Catalytic cracking aid for increasing propylene yield, and preparation method thereof

A technology of catalytic cracking additives and additives, which is applied in the direction of catalytic cracking, hydrocarbon cracking to produce hydrocarbons, and molecular sieve catalysts. Effect of Yield and Propylene Selectivity, Good FCC Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

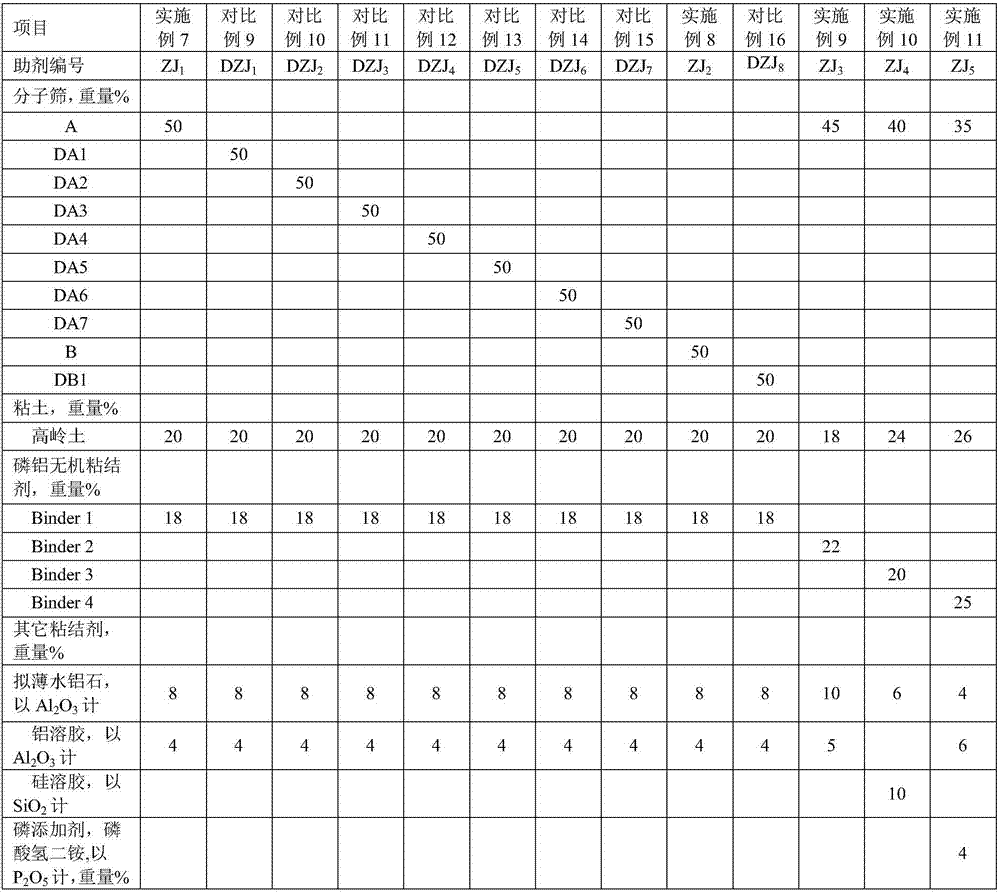

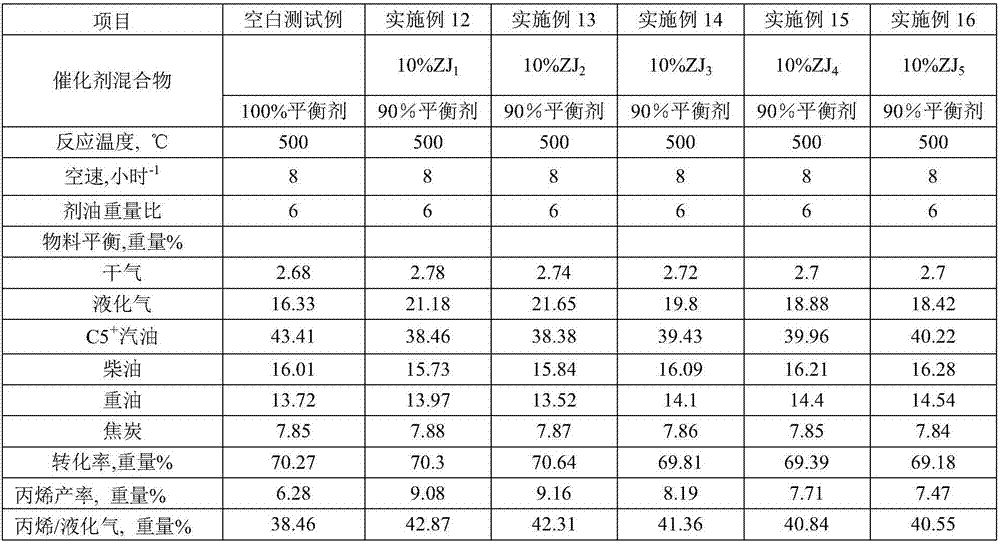

Examples

Embodiment approach

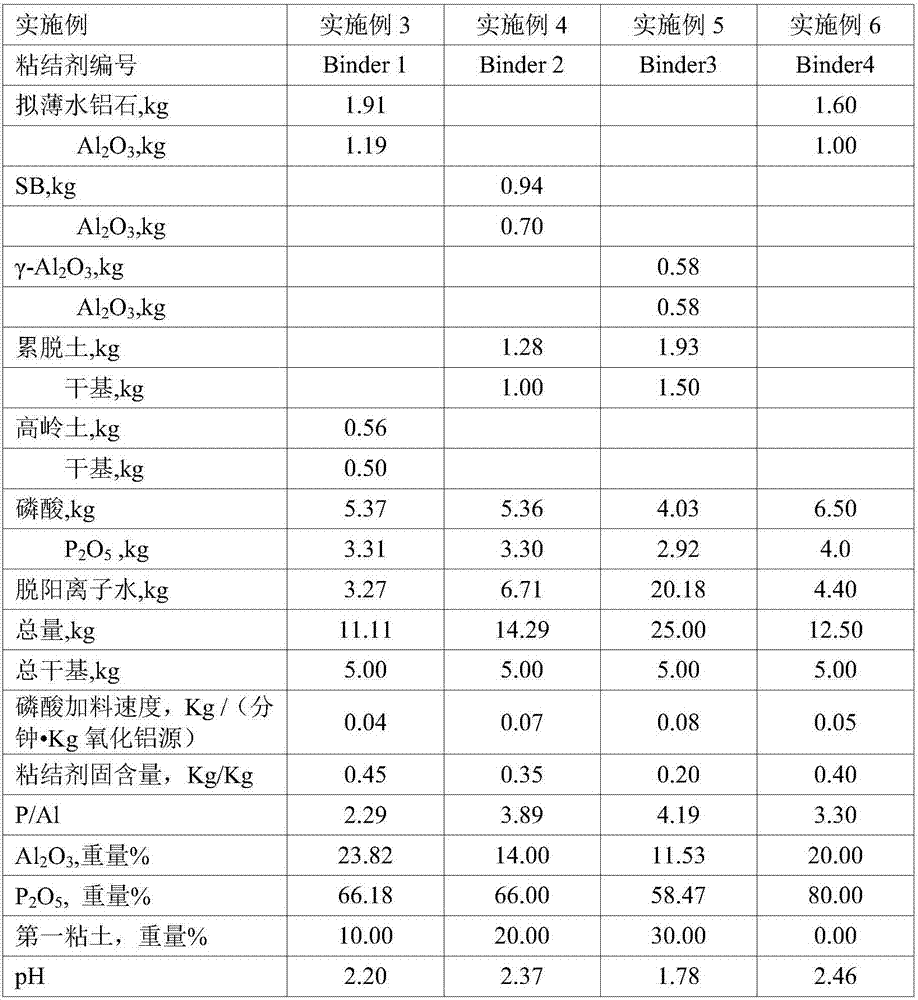

[0031] A specific embodiment, based on the dry basis weight of the phosphorus-aluminum inorganic binder, the phosphorus-aluminum inorganic binder includes Al 2 o 3 15-40% by weight aluminum component, with P 2 o 5 45-80% by weight of the phosphorus component and 0-40% by weight of the first clay based on dry weight, and its P / Al weight ratio is 1.0-6.0, the pH value is 1-3.5, and the solid content is 15- 60% by weight; for example including Al 2 o 3 15-40% by weight aluminum component, with P 2 o 5 A phosphorus component of 45-80% by weight and a first clay of 1-40% by weight on a dry basis; preferably containing Al 2 o 3 15-35% by weight of the aluminum component, as P 2 o 5 50-75% by weight of the phosphorus component and 8-35% by weight of the first clay on a dry basis, the P / Al weight ratio is preferably 1.2-6.0, more preferably 2.0-5.0, and the pH is preferably 1.5 -3.0.

[0032] Another specific embodiment, based on the dry basis weight of the phosphorus-alumi...

Embodiment 1

[0077] Filter the mother liquor from the crystallized IM-5 molecular sieve (produced by Changling Catalyst Factory), wash with water, filter and dry; roast the dried molecular sieve in the air for 6 hours at a roasting temperature of 550°C to remove the templating agent therein Get the above-mentioned molecular sieve 100g (dry basis) and add in 1000g 2.4% by weight of NaOH solution, heat up to 65°C, react for 30min, cool to room temperature rapidly, filter, wash until the filtrate is neutral. Then, add 800g water to the filter cake to make a slurry, add 40g NH 4 Cl, heated to 75°C, exchanged for 1h, to Na 2 O content is lower than 0.2% by weight, filters, washes, and obtains molecular sieve filter cake; Get above-mentioned molecular sieve filter cake 50g (dry basis) and add water and be mixed with the molecular sieve slurry of solid content 10% by weight, add oxalic acid 5g in stirring, then 35g hydrochloric acid ( Mass fraction 10%) and 28g fluosilicic acid (mass fraction 3%...

Embodiment 2

[0093] Filter the mother liquor from the crystallized IM-5 molecular sieve (produced by Changling Catalyst Factory), wash with water, filter and dry; roast the above-mentioned dried molecular sieve in air for 8 hours at a roasting temperature of 550°C to remove the templating agent therein Take 100g (dry basis) of the above-mentioned molecular sieve and add it to 1500g 2.3% by weight of NaOH solution, heat up to 60°C, react for 45min, cool to room temperature rapidly, filter, and wash until the filtrate is neutral. Then, add 800g water to the filter cake to make a slurry, add 40g NH 4 Cl, heated to 75°C, exchanged for 1h, to Na 2 O content is lower than 0.2% by weight, filters, washes, obtains molecular sieve filter cake; Get above-mentioned molecular sieve filter cake 50g (dry basis) and add water and be mixed with the molecular sieve slurry of solid content 10% by weight, add citric acid 4g in stirring, then 10g sulfuric acid ( Mass fraction 10%) and 45g fluosilicic acid (m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com