Construction muck regenerated soil treatment technology

A construction waste and soil treatment technology, applied in processing production lines, precipitation, sorting, crushing, cleaning and screening of construction waste, can solve problems such as inability to use for farming, destroying cultivated land, and large dust, and achieving extended periods of time. The effect of ecological industry chain, reducing pollution and avoiding dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

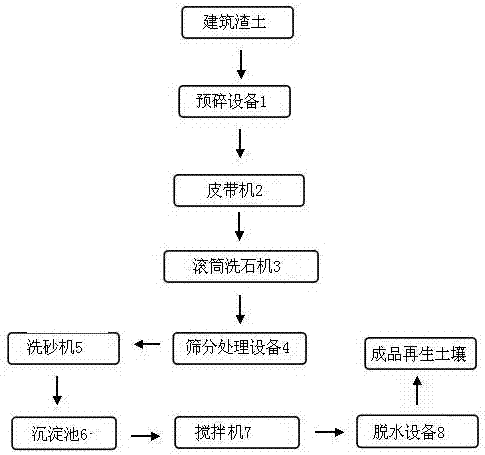

[0019] Embodiment 1: as figure 1 Shown:

[0020] A construction dregs regenerated soil treatment technology, which consists of the following steps: feeding → manual sorting before primary crushing → manual sorting on the conveyor belt machine → passing through the upper iron remover → passing through the lower iron remover → entering the drum stone washing machine and adding water for stirring Grind thoroughly to separate the soil debris→Sieve the mud to screen out the debris→Slurry enters the sand washing machine to remove sand→Mud overflows into the sedimentation tank→Soil settles and solidifies→Enters the mixer to stir with organic matter and additives→Dehydration and solidification→The finished product Plantable soil.

[0021] Before the construction dregs enter the pre-crushing equipment 1 for primary crushing, the operator will pick out the large pieces of sundries. After the construction dregs are initially crushed into materials whose diameter does not exceed the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com