Welding system suitable for steel containment welding seam

A steel containment and welding system technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the welding state cannot be controlled in real time, the quality is greatly affected by human factors, and the manual welding of steel containment Low efficiency and other issues, to reduce the impact of human on data, realize real-time display, and reduce the dependence on welder skill level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

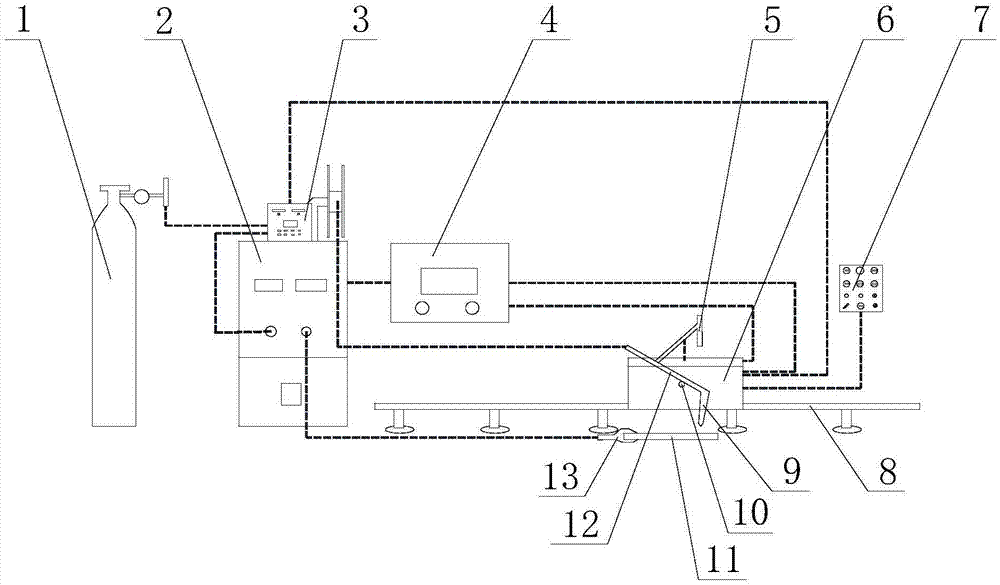

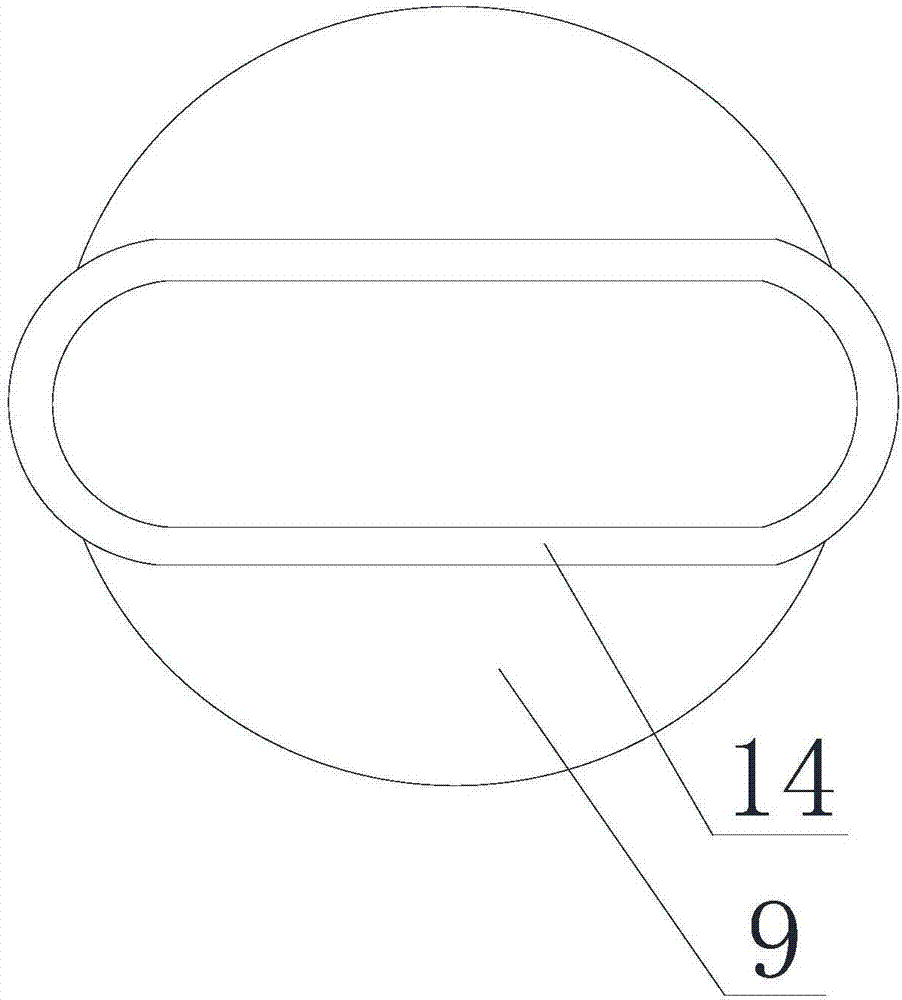

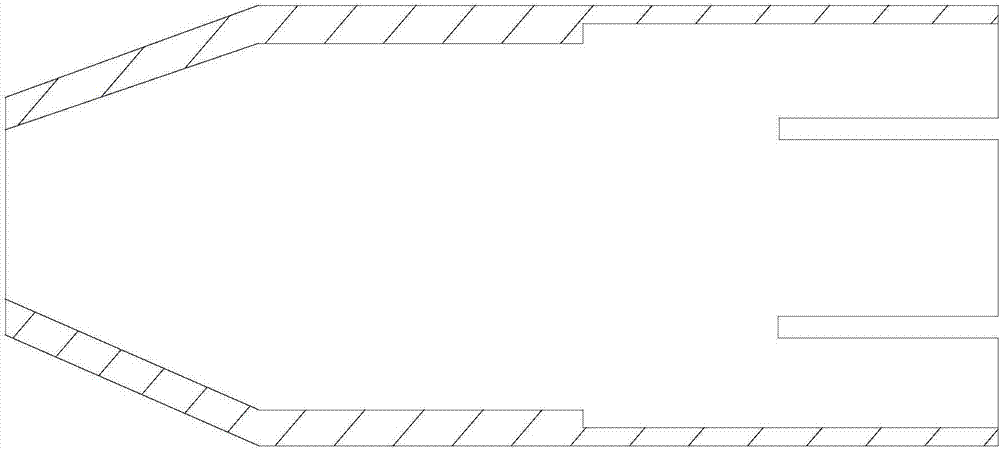

[0030] Such as figure 1 As shown, a welding system suitable for steel containment welds, its hardware structure includes an electrical device, a traveling device, a control device, a record storage device 4 and a visual tracking device 5, and the electrical device includes a power supply 2, a wire feeder 3. Air supply device 1 and welding torch 9, and gas supply device 1 is connected to wire feeder 3, wire feeder 3 is connected to power supply 2, welding torch 9 is connected to wire feeder 3 to send the welding wire through the welding torch, and the traveling device includes welding trolley 6 , the control box 7 and the walking track 8, the control box 7 is connected with the welding trolley 6, the welding trolley 6 is arranged on the walking track 8 and can move along the walking track 8, the welding torch clamping mechanism 12 and the swinger are installed on the welding trolley 6 10. The welding torch clamping mechanism 12 is connected to the swinger 10 and the welding tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com