Magnetorheological elastomer integral forming device based on multi-field coupling effect

A magnetorheological elastomer and molding device technology, applied in the fields of material science and instrumentation, can solve the problems that the microscopic chain structure cannot be adapted to the application environment, increase unfavorable influencing factors, and the process is cumbersome, so as to simplify the material preparation process. , the effect of reducing adverse factors and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

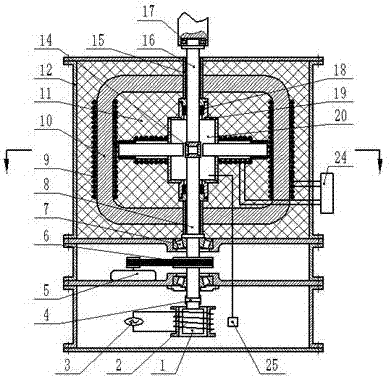

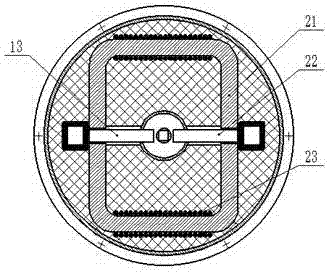

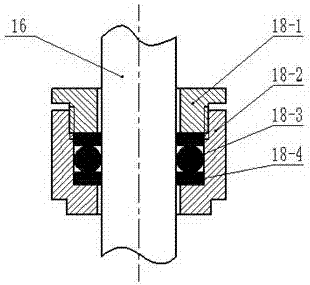

[0026] Example 1 Preparation of natural rubber-based magnetorheological elastomer with inclined chain-like microstructure using the inventive device

[0027] During material preparation, the mixed mixture is injected into the mold 14, and the mold 14 is placed in the holding furnace 20 of the integrated magnetorheological elastomer molding device. In the pre-structuring stage, the power frequency induction power supply 3 is controlled to make the temperature in the mold 14 Stabilize at 80°C, do not activate the motor 5, control the excitation power supply 24 to pass the same current through the two coils 9 and 23, so that a slanted uniform magnetic field with a field strength of 600mT at an angle of 45° to the horizontal line is generated around the mold, and the outside is controlled. Set the pressure machine (not shown in the figure) to load 1MP pressure for 20 minutes, the soft magnetic particles in the mixed material form a chain arrangement in the direction of the magnetic...

Embodiment 2

[0028] Example 2 Preparation of a natural rubber-based magnetorheological elastomer with a helical chain microstructure using the inventive device

[0029]During material preparation, the mixed mixture is injected into the mold 14, and the mold 14 is placed in the holding furnace 20 of the integrated magnetorheological elastomer molding device. In the pre-structuring stage, the power frequency induction power supply 3 is controlled to make the temperature in the mold 14 Stable at 80°C, start the motor 5 to drive the small pulley 6 and the mold 14 to rotate at a certain angular speed, control the excitation power supply 24 to pass a certain amount of current on the coils 9 and 23, so that a spiral field strength along the vertical direction is generated around the mold For a uniform magnetic field of 600mT, control an external press (not shown in the figure) to load 1MP pressure for 20 minutes, and the soft magnetic particles in the mixed material form a chain arrangement in the...

Embodiment 3

[0030] Example 3 Preparation of Polyurethane-Based Magnetorheological Elastomer with Horizontal Chain Microstructure Using the Invention Device

[0031] During material preparation, the mixed mixture is injected into the mold 14, and the mold 14 is placed in the holding furnace 20 of the integrated magnetorheological elastomer molding device. In the pre-structuring stage, the power frequency induction power supply 3 is controlled to make the temperature in the mold 14 Stable at 60°C, do not activate the motor 5, control the excitation power supply 24 to pass current on the coil 23, so that a uniform magnetic field with a field strength of 600mT along the horizontal direction is generated around the mold, and control the external press (not shown in the figure) Load 1MP pressure for 30 minutes, the soft magnetic particles in the mixed material form a chain arrangement in the direction of the magnetic field and initially solidify; then in the curing molding stage, turn off the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com