Integrated antenna shell for Mars exploration landing rover and preparation method thereof

A patrol and shell technology, applied in antennas, antenna parts, radiation unit covers, etc., can solve the problems of poor resistance to high and low temperature cycle performance in space, long molding cycle, and poor dimensional stability of components, so as to eliminate the need for placement. The effect of structural space, improving space utilization, and simplifying structural form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing an integrated antenna housing for a Mars exploration and landing rover, comprising the following steps:

[0035] Step 1, shell forming mold manufacturing;

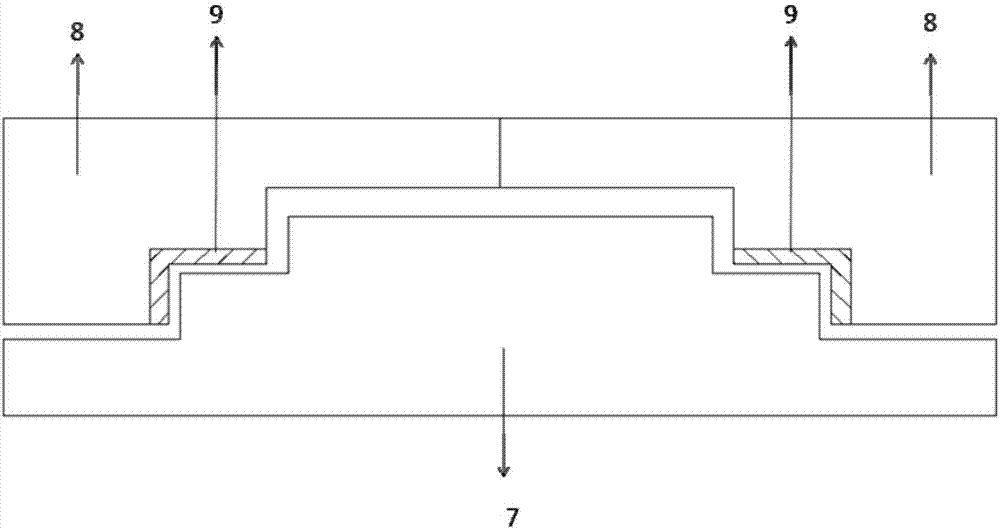

[0036] Such as image 3As shown, the shell forming mold is made of steel, including the main body male mold 7, the block female mold 8 and the "L-shaped" auxiliary silicone rubber soft mold 9, which is used for curing the shell 1, and the "L-shaped" auxiliary silicone rubber The soft mold 9 is located at the step-shaped surface contact position between the main body male mold 7 and the segmented female mold 8, the outer segmented female mold 8 is pressed tightly on the main body male mold 7, and each segmented female mold 8 is in a free state without pins, screws, etc. Fixed connection in a position-limiting way, through the freely movable external block female mold 8 and the internal "L-shaped" auxiliary silicone rubber soft mold 9 to jointly realize the pressure transfer load; wherein, the ...

Embodiment 1

[0054] A method for preparing an integrated antenna housing for a Mars exploration and landing patrol device, comprising the following steps:

[0055] Step 1, shell forming mold manufacturing;

[0056] Such as image 3 As shown, the shell forming mold is made of steel, including the main body male mold 7, the block female mold 8 and the "L-shaped" auxiliary silicone rubber soft mold 9, which is used for curing the shell 1, and the "L-shaped" auxiliary silicone rubber soft mold Die 9 is located at the step-shaped surface contact position between main body male die 7 and segmented female die 8, the outer segmented female die 8 is tightly pressed on the main body male die 7, and each segmented female die 8 is in a free state without pins, screws, etc. It is fixedly connected in a positional way, and the external segmented female mold 8 that can move freely and the internal "L-shaped" auxiliary silicone rubber soft mold 9 jointly realize the pressure transfer load; among them, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com