Corrosion-resistant freeze-thaw resistant mortar and preparation method thereof

A technology of anti-freeze-thaw and mortar, which is applied in the field of anti-corrosion freeze-thaw anti-freeze mortar and its preparation, and can solve problems such as destruction, freeze-thaw denudation, and persistent hazards of dam bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

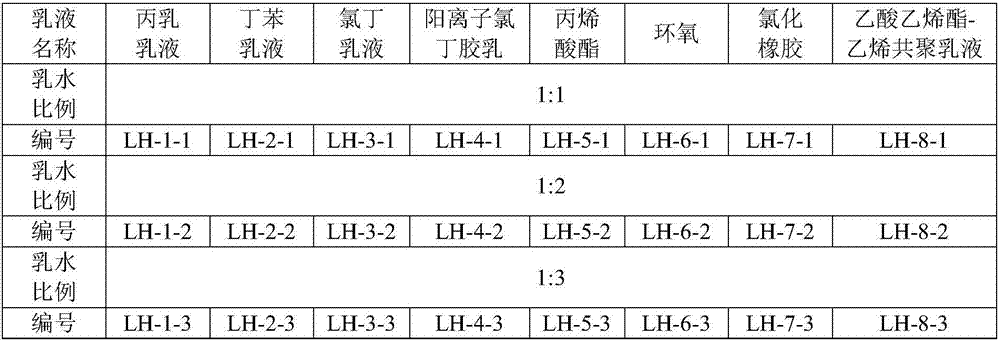

Image

Examples

Embodiment 1-4

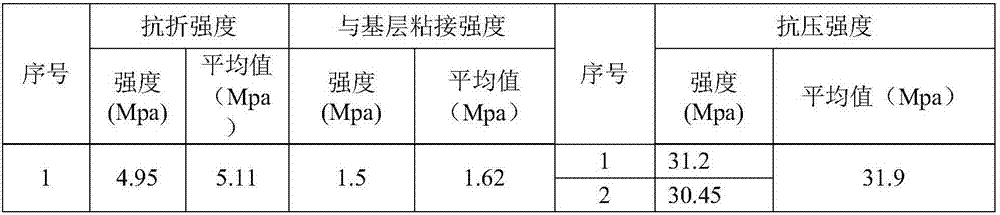

[0083] The emulsion formula is: in terms of mass percentage, 20wt% of cationic neoprene latex, 20wt% of vinyl acetate-ethylene copolymer emulsion, and the rest is drinking water;

[0084] The powder formula is as shown in Table 9 below. The specific preparation process is as follows: mix the powder and emulsion at a mass ratio of 4:1 at 300rpm and stir for 5 minutes to obtain a mortar product, in which the particle size of the coarse sand is 1.5mm, and the mesh particle size of the fine sand is 20-100 Mesh, the length of the hollow fiber is 6mm.

[0085] Table 9 mortar powder formula (kg)

[0086] group

Embodiment 5

[0088] The specific formula and preparation process are the same as in Example 4, except that among the PP fibers, the length of the PP fibers below 6 mm is 1 kg, and the length of the remaining PP fibers is 12 mm.

Embodiment 6

[0090] The specific formula and preparation process are the same as in Example 4, except that the particle size of the coarse sand is 1.2mm, the mesh particle size of the fine sand is 40-60 mesh, and the length of the hollow fiber is 5mm. Among the PP fibers, the length of the PP fibers below 5mm is 1.5kg, and the length of the remaining PP fibers is 13mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com