EPS output shaft

A technology of output shaft and alloy steel, which is applied in the field of alloy steel materials, can solve problems such as wear and tear, and achieve the effects of improving comprehensive performance, suppressing brittleness, and improving oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

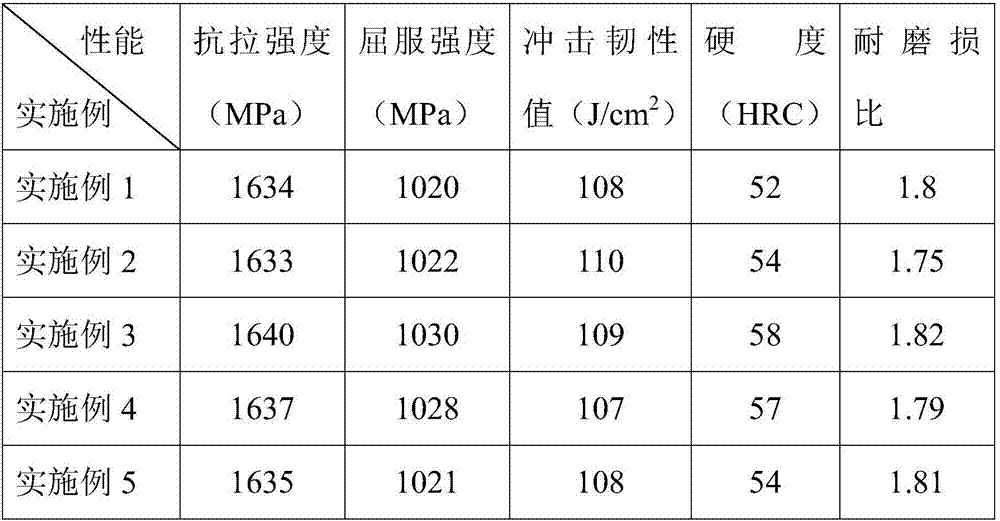

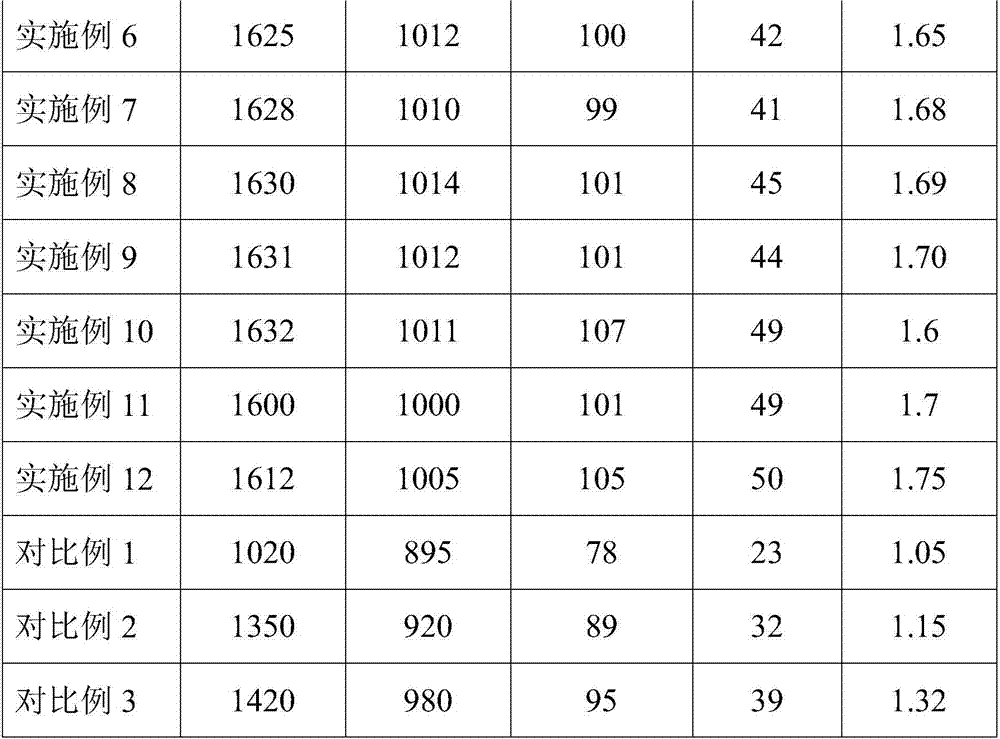

Examples

Embodiment 1

[0031] Press molding: Weigh alloy steel raw materials, ball mill them into powder, and then press them with layered graphite, flake graphite, paraffin, and zinc stearate; wherein, the alloy steel raw materials specifically include the following components by mass percentage: C: 0.24%, Si: 0.26%, Mn: 0.42%, Ni: 0.12%, Cr: 0.95%, Mo: 0.20%, B: 0.02%, the balance is Fe; the amount of layered graphite added is 1.2% of the quality of the alloy steel raw material, The amount of flake graphite added is 0.4% of the mass of the alloy steel raw material, the amount of paraffin wax added is 0.8% of the mass of the alloy steel raw material, the amount of zinc stearate added is 0.65% of the mass of the alloy steel raw material; the pressing pressure is 600MPa ;

[0032] Pre-firing and cooling: pre-fired for 305 minutes in a hydrogen atmosphere at 800°C, and water-cooled to obtain a pre-fired billet;

[0033] Recompression: Recompress the calcined billet at 700MPa;

[0034] Feeding rare e...

Embodiment 2

[0038] Press molding: Weigh alloy steel raw materials, ball mill them into powder, and then press them with layered graphite, flake graphite, paraffin, and zinc stearate; wherein, the alloy steel raw materials specifically include the following components by mass percentage: C: 0.25%, Si: 0.28%, Mn: 0.44%, Ni: 0.13%, Cr: 0.99%, Mo: 0.21%, B: 0.03%, the balance is Fe; the amount of layered graphite added is 1.23% of the quality of the alloy steel raw material, The addition of flake graphite is 0.41% of the mass of the alloy steel raw material, the addition of paraffin is 0.81% of the mass of the alloy steel raw material, the addition of zinc stearate is 0.66% of the mass of the alloy steel raw material; the pressure of pressing is 615MPa ;

[0039] Pre-firing and cooling: Pre-fired for 31 minutes in a hydrogen atmosphere at 807°C, and water-cooled to obtain a pre-fired billet;

[0040] Recompression: Recompress the calcined billet at 705MPa;

[0041] Feeding rare earth wires:...

Embodiment 3

[0045] Press molding: Weigh alloy steel raw materials, ball mill them into powder, and then press them with layered graphite, flake graphite, paraffin, and zinc stearate; wherein, the alloy steel raw materials specifically include the following components by mass percentage: C: 0.26%, Si: 0.29%, Mn: 0.46%, Ni: 0.15%, Cr: 1.05%, Mo: 0.23%, B: 0.035%, the balance is Fe; the amount of layered graphite added is 1.26% of the quality of the alloy steel raw material, The addition of flake graphite is 0.42% of the quality of the alloy steel raw material, the addition of paraffin is 0.83% of the quality of the alloy steel raw material, and the addition of zinc stearate is 0.68% of the quality of the alloy steel raw material; the pressure of pressing is 625MPa ;

[0046] Pre-firing and cooling: pre-fired at 813°C for 32 minutes in a hydrogen atmosphere, and water-cooled to obtain a pre-fired billet;

[0047] Recompression: Recompress the calcined billet at 710MPa;

[0048] Feeding rar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com