Shea butter armor nutrition cream and processing method thereof

A technology of nutrient cream and shea butter, which is applied in manicure, pharmaceutical formulations, skin care preparations, etc. It can solve the problems of black hands, long drying time, and large radiation, and achieve the effect of isolating harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

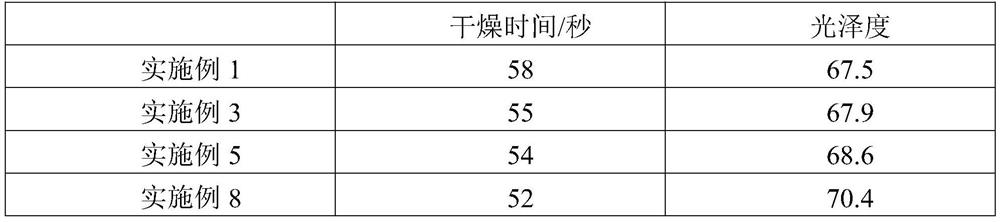

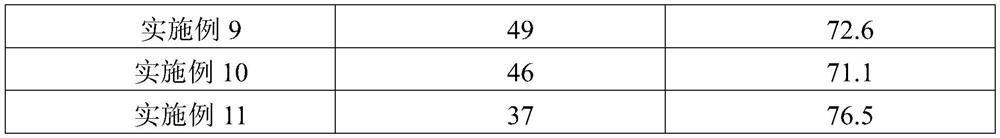

Examples

Embodiment 1

[0055] Shea butter armor nutrient cream comprises the following components by weight:

[0056] 3.2 parts of shea butter, 0.5 parts of rose essential oil, 1 part of silk oil, 0.005 parts of calcium gluconate, 0.1 part of dipotassium glycyrrhizinate, 0.5 parts of sodium stearoyl lactylate, 1.5 parts of squalane, 1 part of ethylhexyl palmitate 0.03 parts of ursolic acid, 20 parts of film-forming agent, 0.5 parts of guar gum, 8 parts of water, 3 parts of n-butanol, 9 parts of ethanol, 2 parts of ethyl acetate, and 1.5 parts of hyaluronic acid.

[0057] The film forming agent is a mixture of epoxy resin and polyvinyl alcohol in a mass ratio of 1:1.

[0058] The processing method of the shea butter armor nutrition cream is as follows: Weigh each raw material by weight, mix the raw materials, stir at a speed of 300 rpm for 45 minutes under the condition of heating in a water bath at 55°C, and cool naturally to obtain milk Mugu Armor Nutrient Balm.

Embodiment 2

[0060] Shea butter armor nutrient cream comprises the following components by weight:

[0061] 3.2 parts of shea butter, 0.5 parts of rose essential oil, 1 part of silk oil, 0.005 parts of calcium gluconate, 0.1 part of dipotassium glycyrrhizinate, 0.5 parts of sodium stearoyl lactylate, 1.5 parts of squalane, 1 part of ethylhexyl palmitate 0.03 parts of ursolic acid, 20 parts of film-forming agent, 0.5 parts of guar gum, 8 parts of water, 3 parts of n-butanol, 9 parts of ethanol, 2 parts of ethyl acetate, and 1.5 parts of hyaluronic acid.

[0062] The film forming agent is epoxy resin modified cornstarch. The preparation method of the epoxy resin-modified cornstarch is as follows, and the parts are all parts by weight: 11 parts of cornstarch are added to 100 parts of water, mixed evenly, gelatinized for 1 hour under the condition of heating in a water bath at 75°C, and the temperature is raised To 90°C, add 4 parts of sodium hydroxide, stir at 90°C at a speed of 200 rpm for ...

Embodiment 3

[0065] Shea butter armor nutrient cream comprises the following components by weight:

[0066] 3.2 parts of shea butter, 0.5 parts of rose essential oil, 1 part of silk oil, 0.005 parts of calcium gluconate, 0.1 part of dipotassium glycyrrhizinate, 0.5 parts of sodium stearoyl lactylate, 1.5 parts of squalane, 1 part of ethylhexyl palmitate 0.03 parts of ursolic acid, 20 parts of film-forming agent, 0.5 parts of guar gum, 8 parts of water, 3 parts of n-butanol, 9 parts of ethanol, 2 parts of ethyl acetate, and 1.5 parts of hyaluronic acid.

[0067] The film forming agent is epoxy resin modified cornstarch. The preparation method of the epoxy resin-modified cornstarch is as follows, and the parts are all parts by weight: 11 parts of cornstarch are added to 100 parts of water, mixed evenly, gelatinized for 1 hour under the condition of heating in a water bath at 75°C, and the temperature is raised To 90°C, add 4 parts of sodium hydroxide, stir at 90°C at a speed of 200 rpm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com