A photocatalytic material cu 2-x s/mn 0.5 cd 0.5 s/mos 2 Its preparation method and application

A photocatalytic material, cu2-xs technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc. solutions, etc., to achieve high commercial application prospects, good photocatalytic performance, and excellent hydrogen production activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

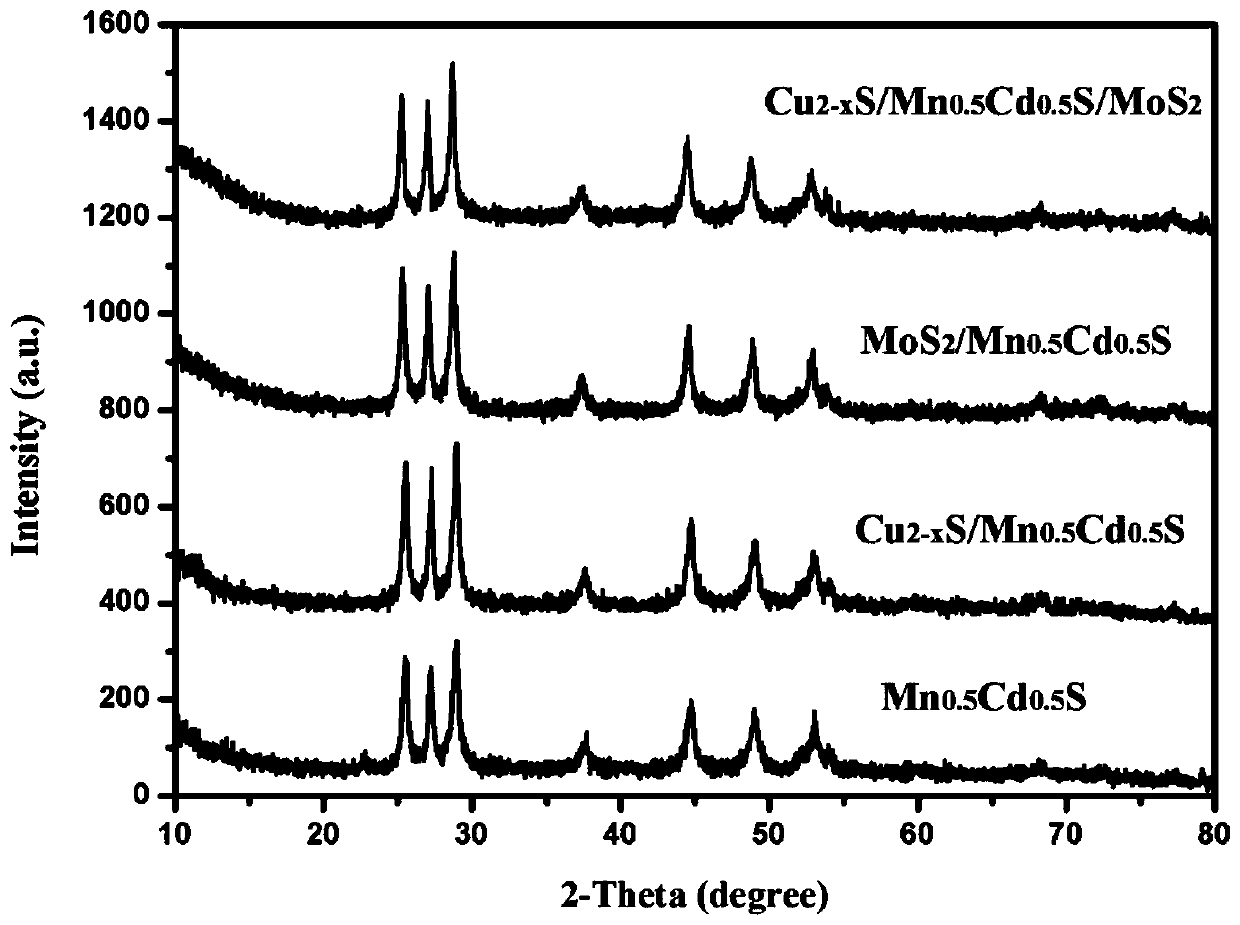

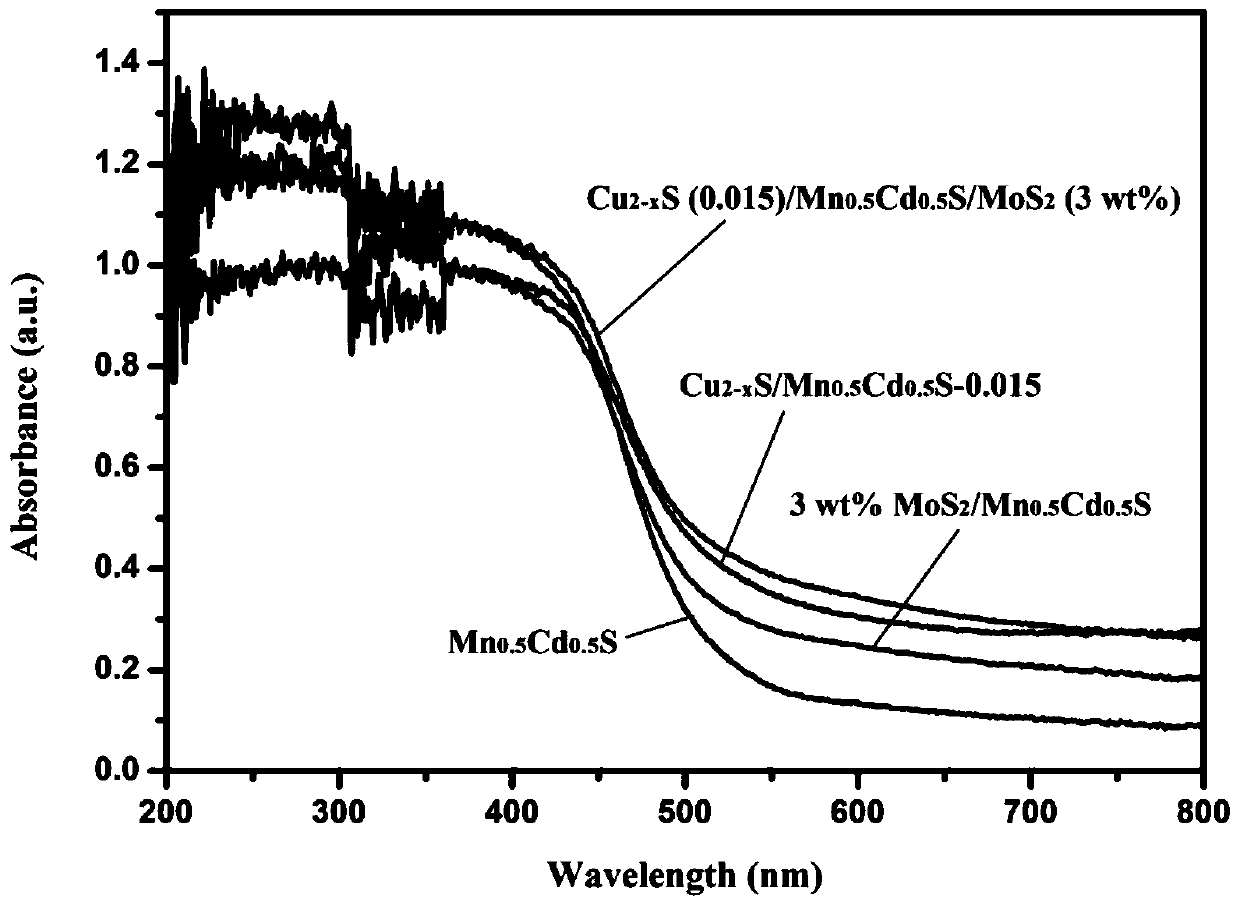

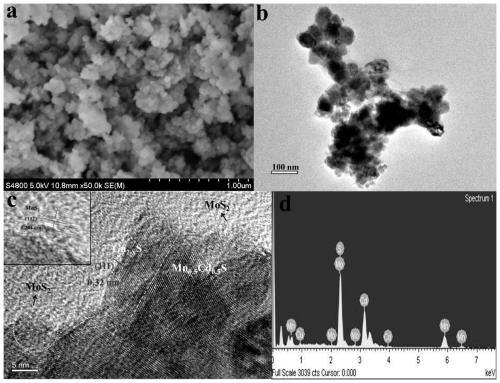

[0037] In one embodiment of the present application, there is provided a Cu 2-x S / Mn 0.5 Cd 0.5 S / MoS 2 The preparation method of composite photocatalytic material, the steps are as follows:

[0038] First prepare the synthetic Mn 0.5 Cd 0.5 The substrate material of S solid solution, and then cleverly use different solubility, in situ loading to get Cu 2-x S-modified Mn 0.5 Cd 0.5 S solid solution, which builds a local P-N junction at the nanoscale. The construction of P-N junction can effectively promote the separation of carriers, and the photogenerated holes flow to Cu 2-x S, photogenerated electrons flow to the base material Mn 0.5 Cd 0.5 S solid solution. The electrons and holes have been effectively separated, and then photoreduction (NH 4 ) 2 MoS 4 A method for directed loading of MoS 2 in Mn 0.5 Cd 0.5 S solid solution on the substrate, thus realizing the space-separated double-cocatalyst-modified Mn 0.5 Cd 0.5 S, as active sites for oxidation and r...

Embodiment 1

[0046] Example 1: Cu 2-x S / Mn 0.5 Cd 0.5 S / MoS 2 Preparation of composite photocatalytic materials

[0047] Specific steps are as follows:

[0048] (1) Preparation of Mn by hydrothermal method 0.5 Cd 0.5 S solid solution:

[0049] 1mmol of Mn(CH 3 COO) 2 4H 2 O and 1 mmol of Cd(CH 3 COO) 2 2H 2 O was dissolved in 35 mL of deionized water and marked as A. 6mmol of L-cystine was dissolved in 35mL of water outside the forest, and the pH value was adjusted to 10.5 with 6mol / L NaOH to dissolve it, marked as B. Slowly add solution A to solution B, continue to stir for 30 minutes, transfer it to a stainless steel reaction kettle, and heat it at 130 degrees for 10 hours.

[0050] (2) Preparation of Cu by in situ ion exchange 2-x S / Mn 0.5 Cd 0.5 S:

[0051] The synthesized Mn 0.5 Cd 0.5 S was ultrasonically dispersed in 100mL of water, and a certain amount of Cu(NO 3 ) 2 The solution was added dropwise to it for ion exchange, while adding Na 2 S and Na 2 SO 3 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com