Dry-wet separation pulping method for kitchen waste (food waste)

A dry-wet separation and food waste technology, which is applied in chemical instruments and methods, electronic waste recovery, recycling technology, etc., can solve the problems of high moisture content in organic colloidal substances, reduce porosity, improve impact load resistance, The effect that is not easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

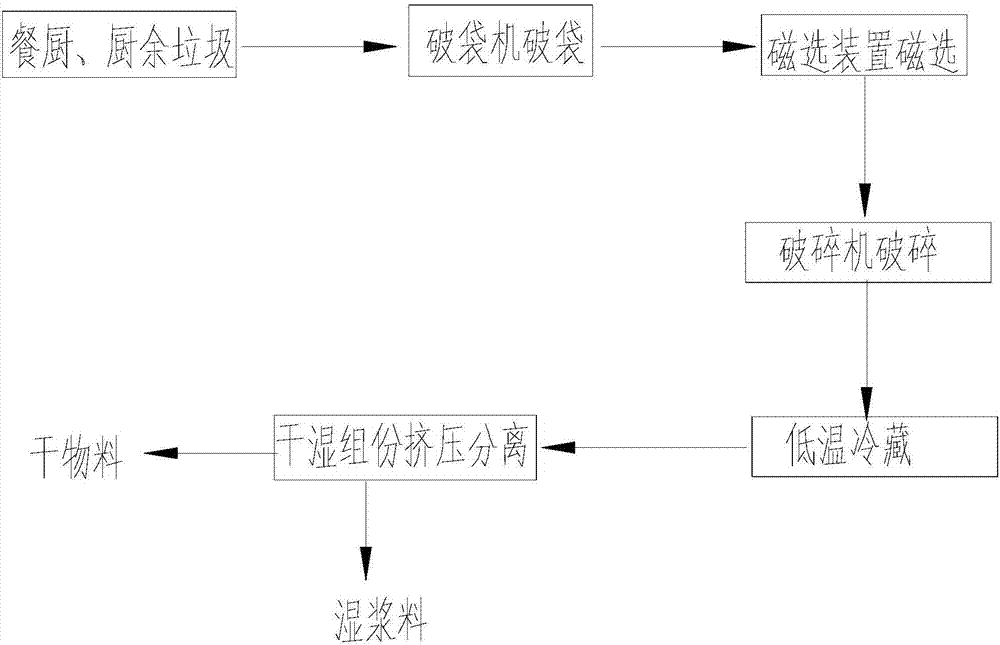

[0025] Examples such as figure 1 As shown, a method for treating kitchen (kitchen waste) waste is used for subdividing the kitchen (kitchen waste) waste so as to obtain better economic benefits and better environmental protection. This method can be mainly divided into low-temperature solidification and solid-liquid separation, and the steps are connected by belt conveying or screw conveying. The steps of the present invention and the equipment used are described in detail below.

[0026] The kitchen (kitchen waste) garbage contains a large amount of organic matter, mainly including some tiles, plastics and the like. The waste is transported to the factory by a special transport vehicle, poured into the discharge hopper, and sent to the bag breaking machine through the conveyor belt for preliminary bag breaking treatment; the follow-up is to obtain a smaller material size and reduce the porosity in the subsequent material extrusion process , to further crush the material. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com