Integrated electric drive power assembly system

A powertrain and electric drive technology, applied in the direction of electric power devices, power devices, electric components, etc., can solve the problems of limited output torque of the drive system, difficulty in high-load working conditions, increased manufacturing and installation difficulties, etc., to achieve Easy to repair and replace, avoid excessive installation axial size, reduce the effect of mechanical interface and electrical interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be further described below with reference to the drawings and embodiments.

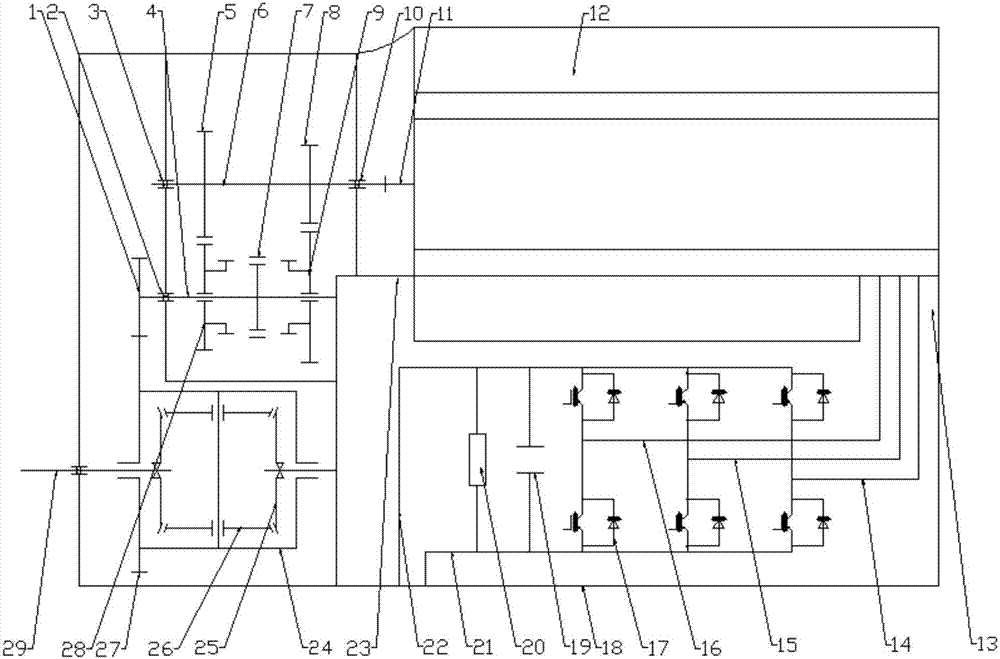

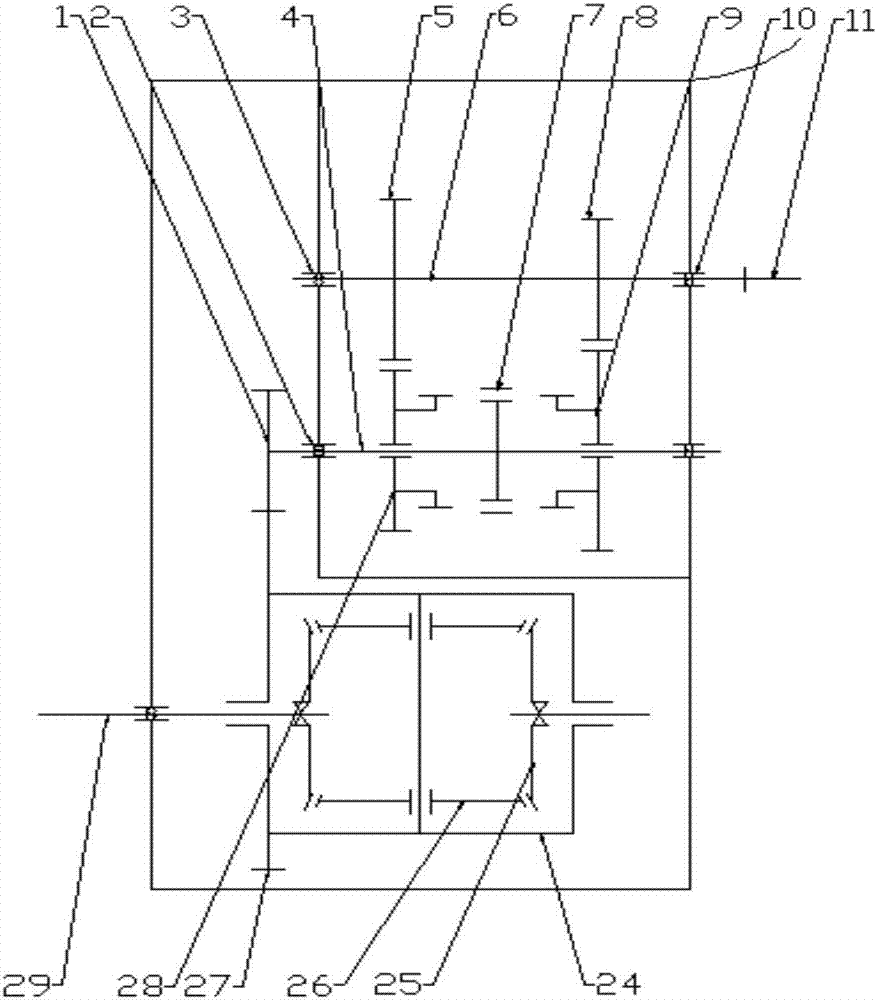

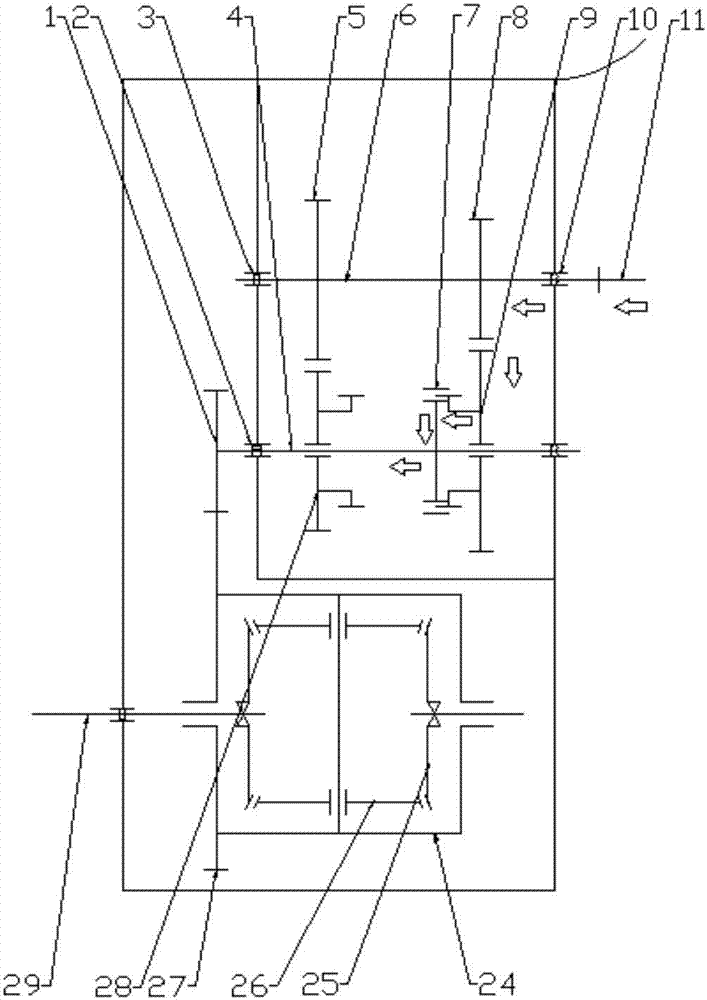

[0028] See figure 1 with figure 2 , The integrated electric drive powertrain system of the present invention includes an inverter 18, a motor 12, a two-speed transmission, a main reducer and left and right half shafts 29. The inverter 18 is composed of a positive bus 22, a negative bus 21, The resistor 20, the capacitor 19, the IGBT group, the three-phase AC output line and the inverter housing are composed of the resistor 20, the capacitor 19, and the IGBT group are arranged between the positive bus 22 and the negative bus 21. The IGBT group is composed of 6 IGBTs 17, An output line is drawn between every two IGBTs, namely U-phase output line 16, V-phase output line 15, and W-phase output line 14, forming a three-phase AC output line. The three-phase AC output line is interfaced with the motor through the inverter 13 is connected to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com