Method for preparing biomass gas, activated carbon and products thereof

A technology of biomass gas and activated carbon, which is applied in the field of preparation of biomass gas, co-product gas and activated carbon, and preparation of activated carbon, which can solve the problems of low specific surface area of activated carbon and low utilization rate of straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

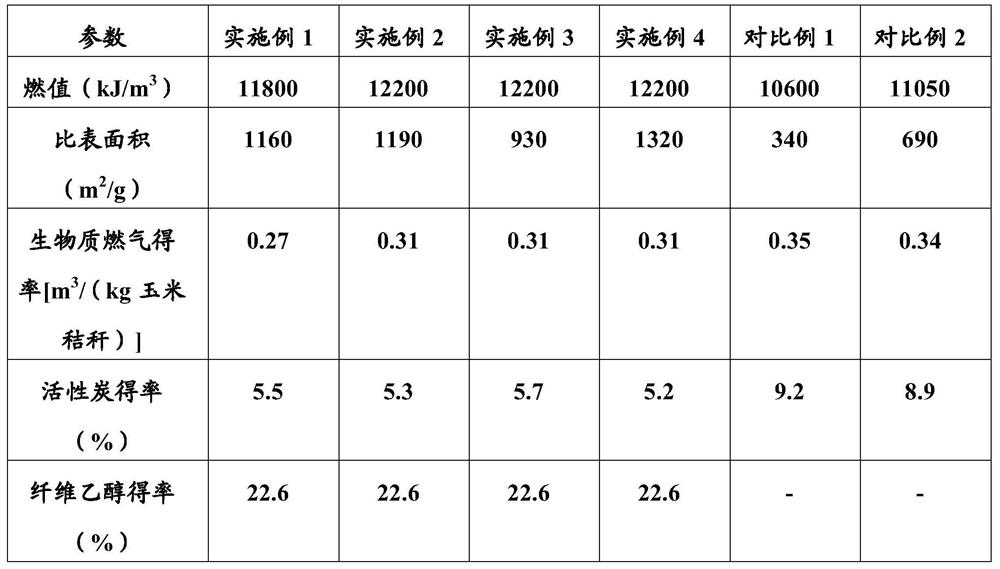

Embodiment 1

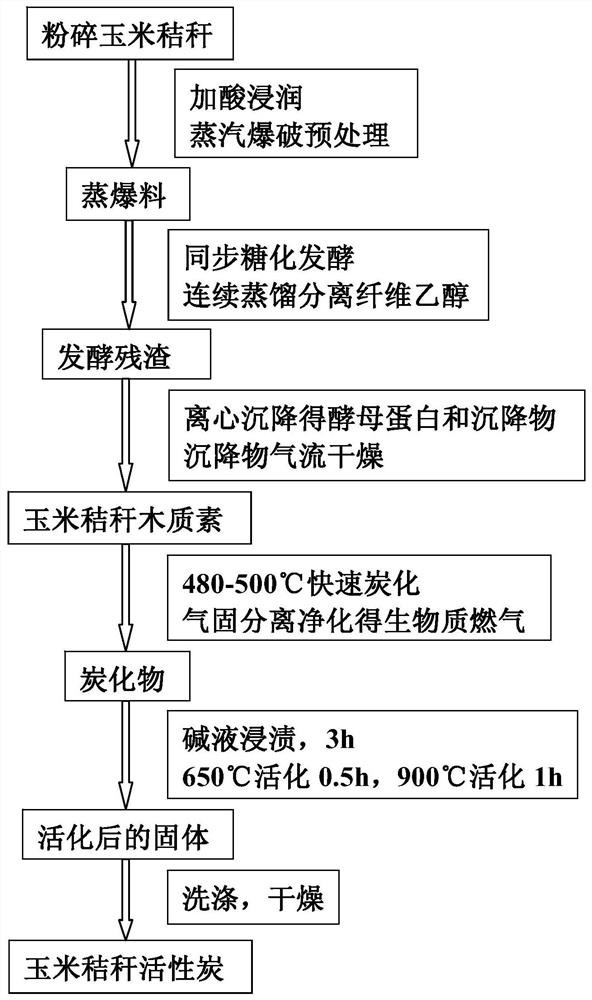

[0069] refer to figure 1 The process shown is to co-produce gas and activated carbon from corn stalks.

[0070] The particle size of the corn stalk is between 20 mm and 30 mm, and the water content is ≤12% (w / w). The corn stalks are soaked with a sulfuric acid solution with a mass concentration of 0.25% for 2 hours, and the dosage of the sulfuric acid solution is 0.40-0.45 kg / (kg corn stalks). Then, the corn stover was pretreated by continuous steam explosion at 195 °C for 6 min. The obtained steamed material is subjected to synchronous saccharification and fermentation reaction, wherein the substrate mass concentration is 10%, the amount of cellulase is 22 FPU / (g cellulose), the yeast concentration is 5g / L, the reaction temperature is 35°C, and the synchronous saccharification and fermentation time 96 hours. The reaction product is continuously distilled to remove cellulosic ethanol, and then after centrifugal sedimentation, the upper light phase component—yeast protein is...

Embodiment 2

[0072] refer to figure 1 The process shown is to co-produce gas and activated carbon from corn stalks.

[0073] The particle size of the corn stalk is between 20 mm and 30 mm, and the water content is ≤12% (w / w). The corn stalks are soaked with a sulfuric acid solution with a mass concentration of 0.25% for 2 hours, and the dosage of the sulfuric acid solution is 0.40-0.45 kg / (kg corn stalks). Then, the corn stover was pretreated by continuous steam explosion at 195 °C for 6 min. The obtained steamed material is subjected to synchronous saccharification and fermentation reaction, wherein the substrate mass concentration is 10%, the amount of cellulase is 22 FPU / (g cellulose), the yeast concentration is 5g / L, the reaction temperature is 35°C, and the synchronous saccharification and fermentation time 96 hours. The reaction product is continuously distilled to remove cellulosic ethanol, and then centrifuged to remove the upper light phase component—yeast protein, and the rema...

Embodiment 3

[0075] refer to figure 1 The process shown is to co-produce gas and activated carbon from corn stalks.

[0076] The particle size of the corn stalk is between 20 mm and 30 mm, and the water content is ≤12% (w / w). The corn stalks are soaked with a sulfuric acid solution with a mass concentration of 0.25% for 2 hours, and the dosage of the sulfuric acid solution is 0.40-0.45 kg / (kg corn stalks). Then, the corn stover was pretreated by continuous steam explosion at 195 °C for 6 min. The obtained steamed material is subjected to synchronous saccharification and fermentation reaction, wherein the substrate mass concentration is 10%, the amount of cellulase is 22 FPU / (g cellulose), the yeast concentration is 5g / L, the reaction temperature is 35°C, and the synchronous saccharification and fermentation time 96 hours. The reaction product is continuously distilled to remove cellulosic ethanol, and then after centrifugal sedimentation, the upper light phase component—yeast protein is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com