Methyl ethyl ketone peroxide production system and production process

A technology of methyl ethyl ketone peroxide and production system, applied in the field of methyl ethyl ketone peroxide production system and production process, can solve problems such as difficult control, personal casualty equipment, easy misoperation, etc., to eliminate hidden dangers of explosion, protect personal safety, and prevent misoperation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

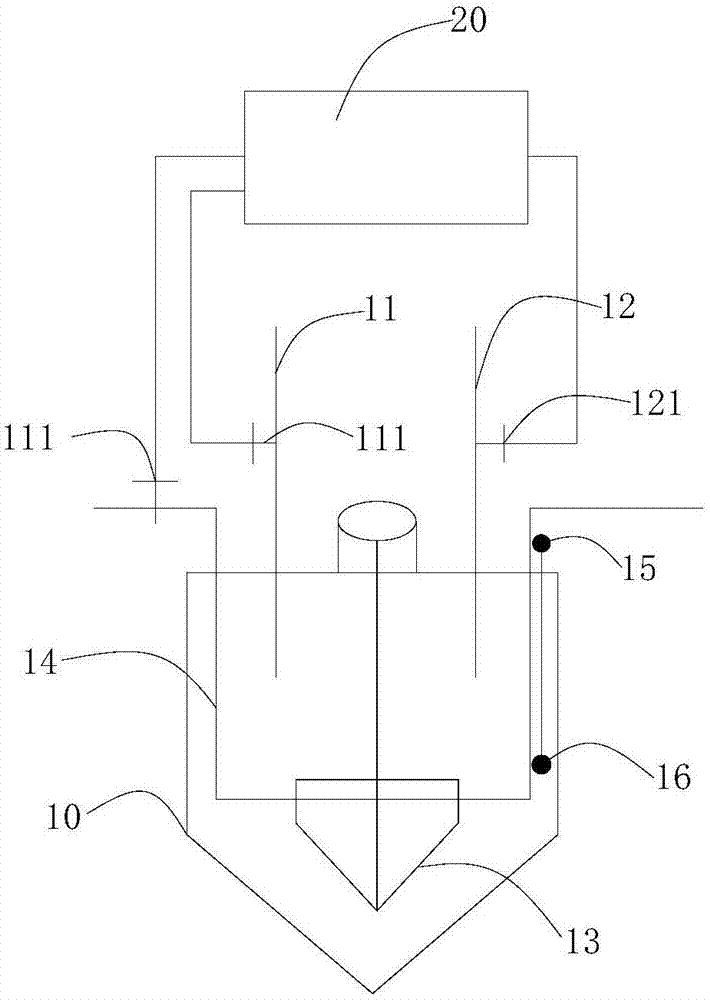

[0053] The methyl ethyl ketone peroxide production system comprises a reactor, the reactor is provided with a butanone feed pipe and a hydrogen peroxide burette, the said butanone feed pipe is provided with a feed valve, and the hydrogen peroxide burette is provided with a drip valve; A stirring device and a cooling device are arranged in the reaction kettle, and the stirring device includes a stirring paddle and a motor that drives the stirring paddle to rotate;

[0054] The methyl ethyl ketone peroxide production system also includes a controller and a display connected to the controller, the controller presets the temperature and the reaction temperature of the cooling water in the cooling device; the reactor is provided with a cooling water temperature sensor and a reaction The temperature sensor, the cooling water temperature sensor and the reaction temperature sensor are respectively connected to the controller signal, the temperature signal sensed by the cooling water te...

Embodiment 2

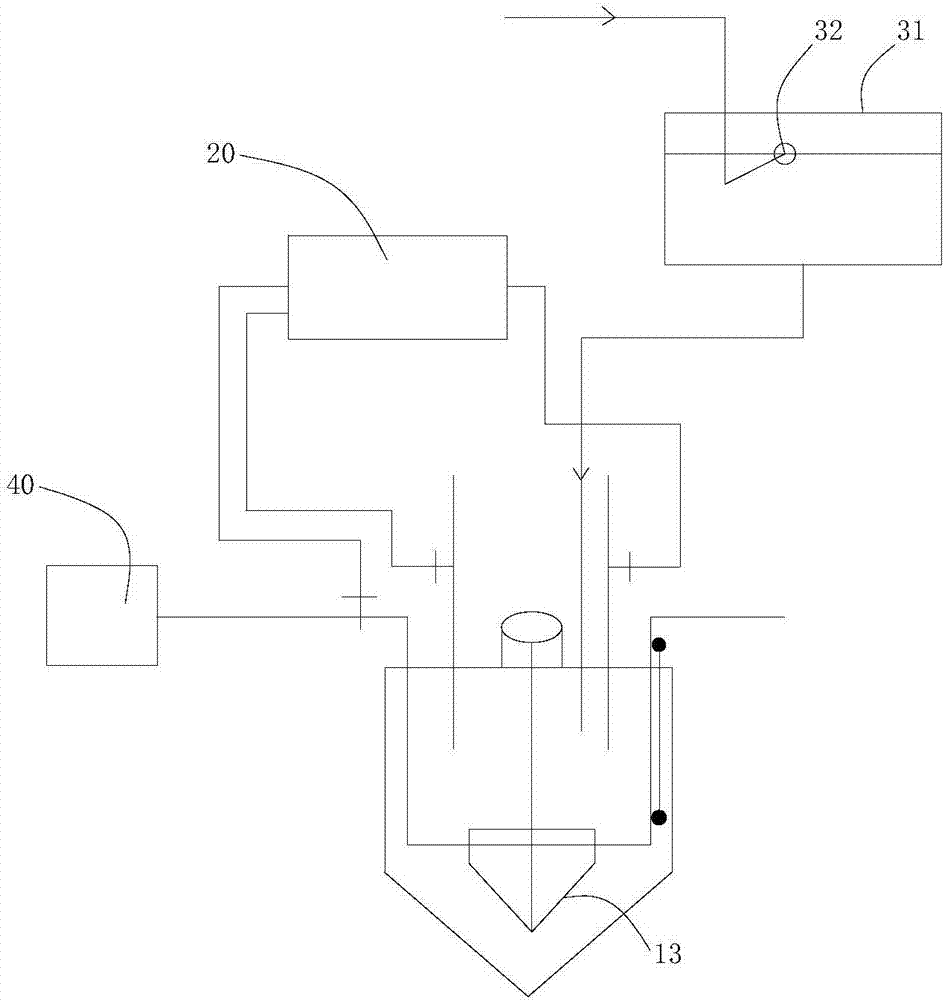

[0057] The methyl ethyl ketone peroxide production system comprises a reactor, the reactor is provided with a butanone feed pipe and a hydrogen peroxide burette, the said butanone feed pipe is provided with a feed valve, and the hydrogen peroxide burette is provided with a drip valve; A stirring device and a cooling device are arranged in the reaction kettle, and the stirring device includes a stirring paddle and a motor that drives the stirring paddle to rotate;

[0058] The methyl ethyl ketone peroxide production system also includes a controller, a display connected to the controller and an alarm, and the temperature and the reaction temperature of the cooling water in the preset cooling device are preset in the controller; the reaction kettle is provided with a cooling water temperature sensor and a reaction temperature sensor, the cooling water temperature sensor and the reaction temperature sensor are connected to the controller signal respectively, the temperature signal...

Embodiment 3

[0062] The production technique of methyl ethyl ketone peroxide adopts the methyl ethyl ketone peroxide production system described in the embodiment of the present invention 1 to produce, and this production process comprises the following steps:

[0063] 1) Add butanone and dimethyl phthalate to the reaction kettle through the butanone feed pipe after metering, and put low-temperature water not exceeding 10°C into the cooling device to cool down the material; then pump the hydrogen peroxide Put it into the metering tank for metering. After the metering is completed, put it into the burette and slowly add it to the reactor, keeping the temperature of the reactor at 22°C; After stirring for 1 hour, let it stand for stratification, the lower layer is the water layer, and the water layer is divided into the waste water treatment tank for treatment.

[0064] 2) Then add diethylene glycol, methanol, and dimethyl phthalate into the reaction kettle, and after fully stirring, the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com