Simple reaction device

A reaction device and a simple technology, applied in the field of simple reaction devices, can solve the problems such as inability to flexibly adjust the chemical reaction rate, inability to achieve the purpose of energy saving, inability to popularize and use widely, etc., so as to facilitate the adjustment of the chemical reaction rate, structure and material setting. Scientific and reasonable, the effect of preventing corrosion from being damaged and failing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

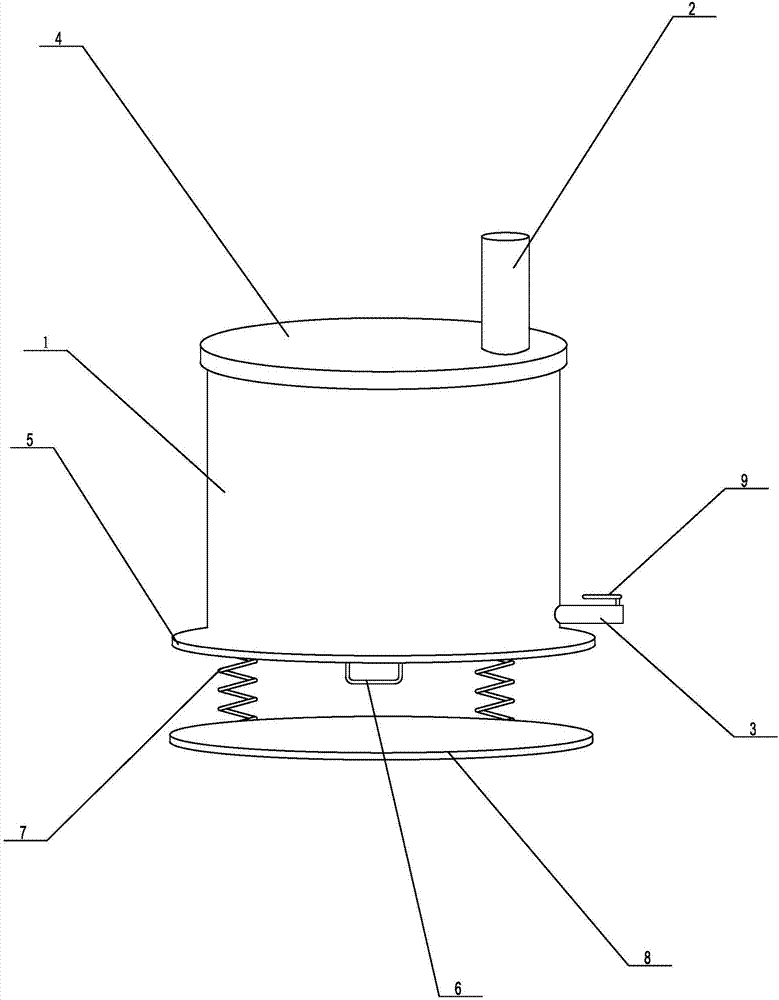

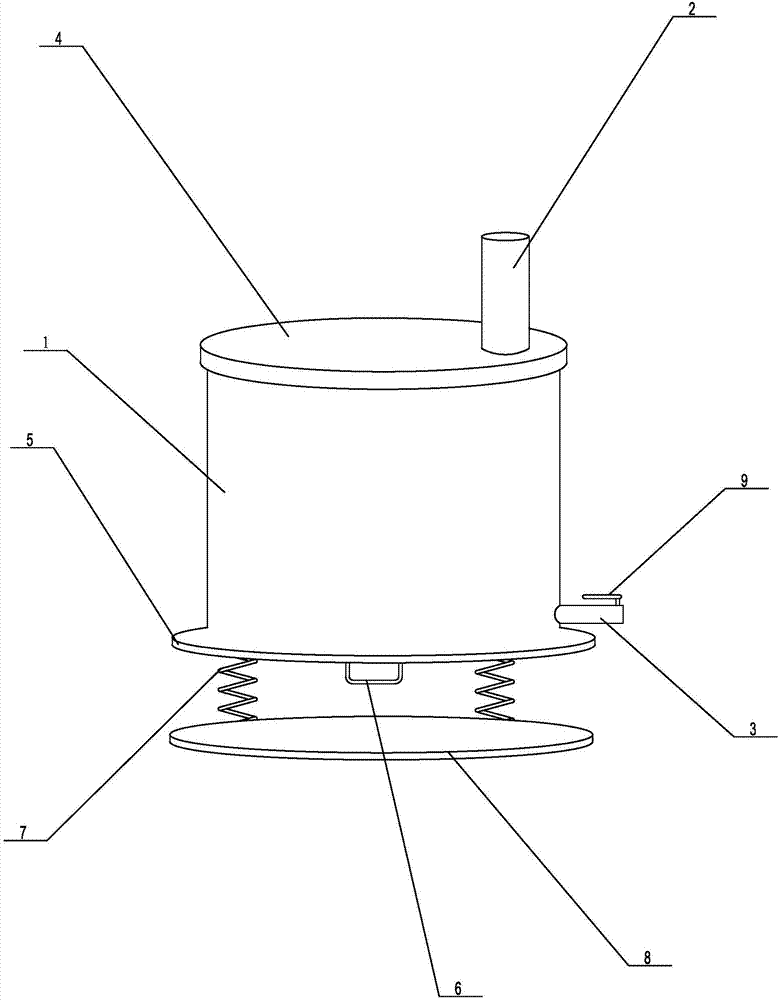

[0016] Such as figure 1 Propose a kind of specific embodiment of the present invention as shown, simple type reaction device, comprise and be cylindrical, and tank body 1 of opening, described tank body 1 is provided with feed pipe 2 and discharge pipe 3, and described feed pipe The pipe 3 is arranged at the lower end of the tank body 1 and is provided with a flow valve 9 thereon. The top end of the tank body 1 is provided with a tank cover 4 which can be connected with it. Through threaded connection, that is, an internal thread is provided on the top of the tank body 1, and an external thread is provided on the tank cover 4, so as to realize the cooperative connection between the tank cover 4 and the tank body 1, and the bottom end of the tank body 1 is connected with an elastic plate 5. The elastic plate 5 is circular, and the diameter of the elastic plate 5 is larger than the diameter of the tank body. Considering anti-corrosion and high-strength performance, the elastic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com