A kind of polyamide resin-based suspension sizing agent for carbon fiber and preparation method thereof

A polyamide resin and carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of unfavorable carbon fiber sizing industrial application, high technical difficulty, complex process, etc., and achieve low cost, good amphiphilicity, and good processing Effects of Performance and Interface Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

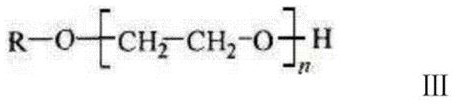

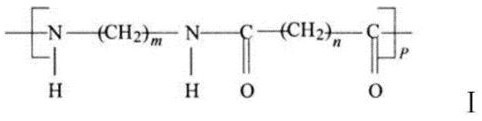

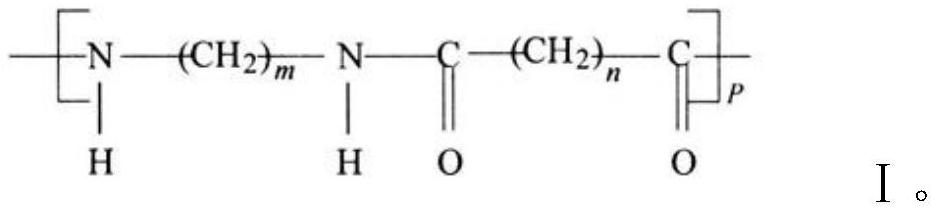

[0034] Mix a certain amount of polyamide resin powder and polyacrylamide evenly for later use; add a certain amount of water into the stainless steel stirring tank A and turn on the mechanical stirring, keep a certain speed, and gradually add the above mixture, and continue stirring for a certain period of time after it is completely added; The above water-containing mixture is transferred to the stainless steel stirring tank B, a certain amount of fatty alcohol polyoxyethylene ether is added, the high-speed emulsifier is turned on, and the material is discharged after emulsifying at a certain speed for a certain period of time. The polyamide powder is from China Petrochemical Co., Ltd., and the polyacrylamide and fatty alcohol polyoxyethylene ether are from BASF Corporation. The solid components of the suspension sizing agents prepared in Examples 1-8 are shown in Table 1, the composition and dosage of the sizing agents are shown in Table 2, and the preparation process paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com