Laser ignition combustion chamber for titanium fire test

A technology of laser ignition and combustion chamber, applied in the application field of titanium alloys, can solve the problems such as the inability to meet the development needs of advanced engines, and achieve the effects of reducing power, compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

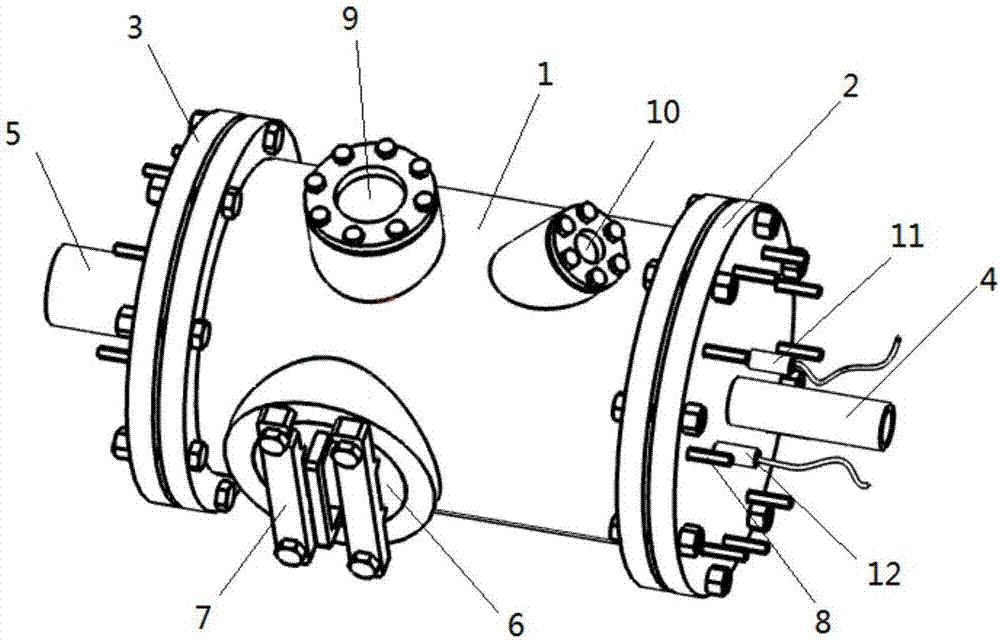

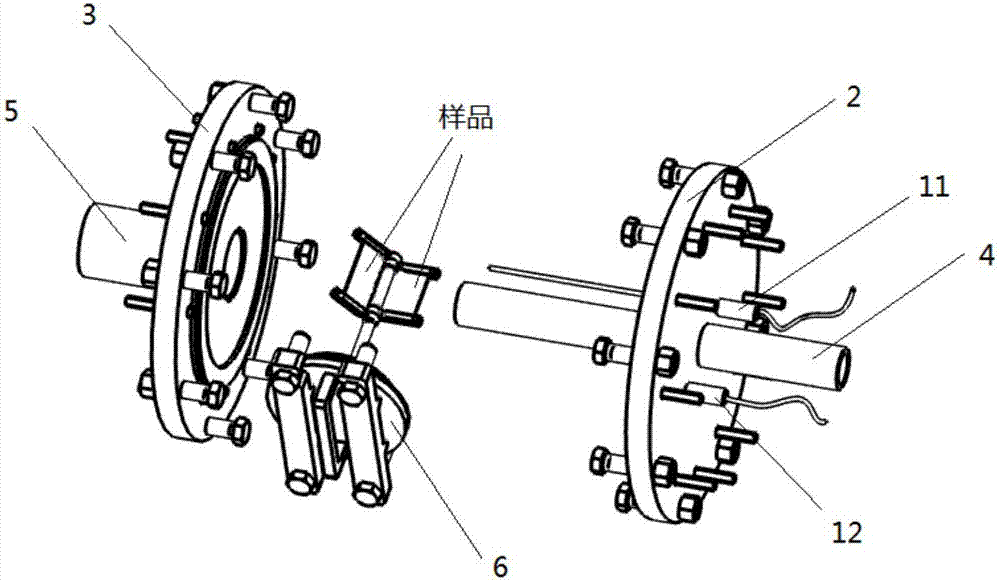

[0050] like figure 1 , 2 As shown in , 3, the shell (1) has a circular cross-section and is made by integral casting. Tables (101), (102), (103) have diameters of 200mm, 120mm and 80mm, respectively. The boss (101) installs the sample holder (6), which is pressed onto the boss (101) by two pressure plates, and the test sample is clamped to the sample holder (6) by the inner and outer splints (601) (602). The observation window (9) is made of quartz glass with a diameter of 88mm. It is fixed to the boss (102) of the observation window by a cover plate with holes through bolts. When the equipment is running, a high-speed camera can be installed directly above the observation window to observe the samples in the cavity. situation, or install an infrared temperature sensor to measure the sample temperature. The laser incident window (10) is located in front of the observation window (9), is made of zinc selenide, and has a diameter of 32mm. The body axis is at an angle of 45°,...

Embodiment 2

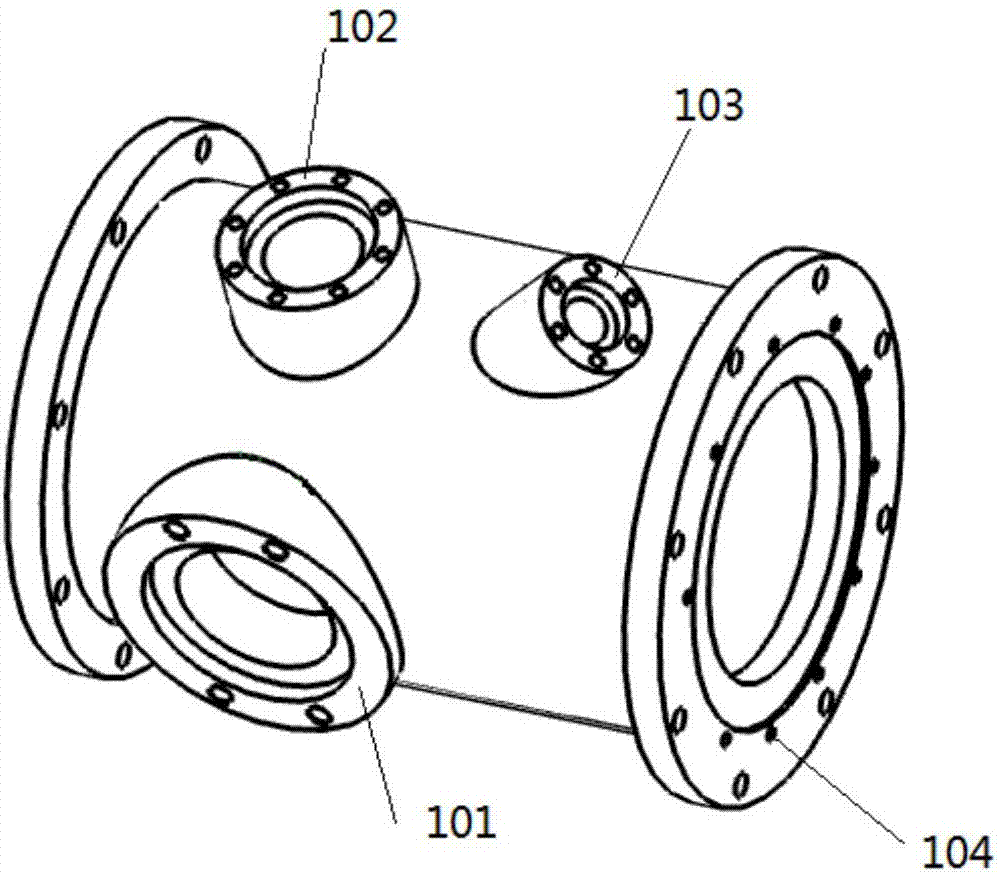

[0052] The shell (1) has a rectangular cross-sectional shape and is welded by four plates with cooling channels (104), and the three bosses (101), (102), and (103) are connected to the shell (1) by welding On the upper side, the boss (102) and the boss (103) are arranged on the upward side, the opening (101) is arranged on the side, so that the observation window (9) on the opening (102) is located directly above the test sample, and the opening (103 The laser incident window (10) on the ) is located at the oblique top of the test sample, the material of the observation window (9) is quartz glass, the material of the laser incident window (10) is zinc selenide, the observation window (9) and the laser incident window (10) There is a sealing ring between the opening of the casing and the casing to prevent the leakage of high temperature and high pressure gas. The opening (103) is arranged obliquely so that the laser beam incident perpendicular to the laser incident window (10) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com