A laser welding method for the narrow space of the casing

A laser welding, narrow space technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of reducing welding deformation problems, long life, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

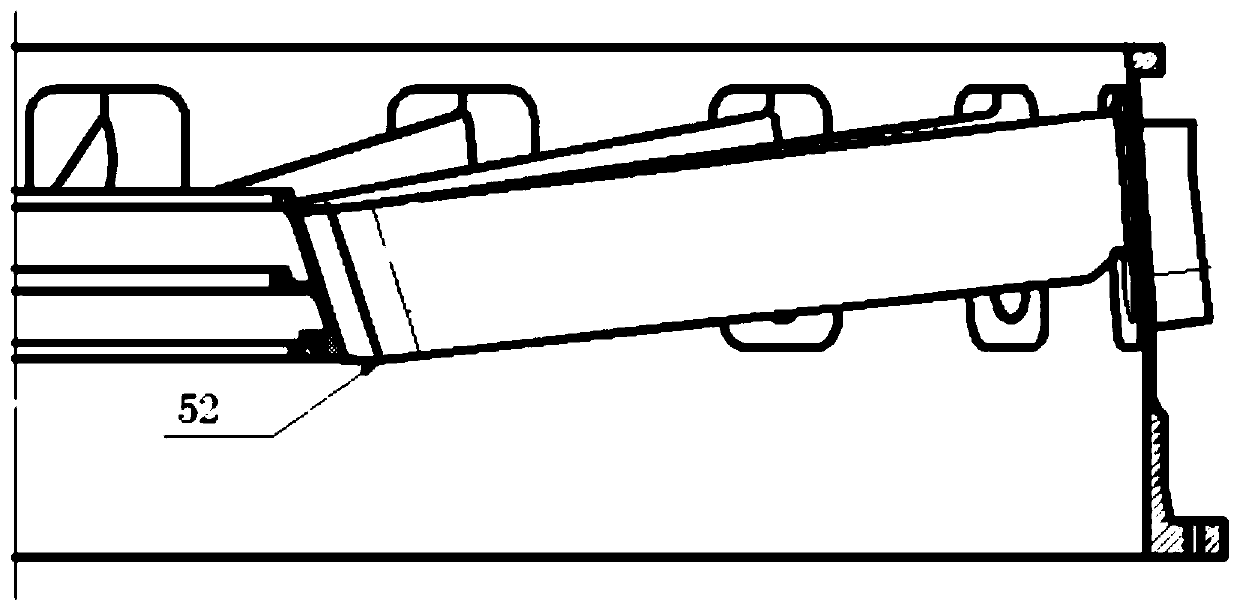

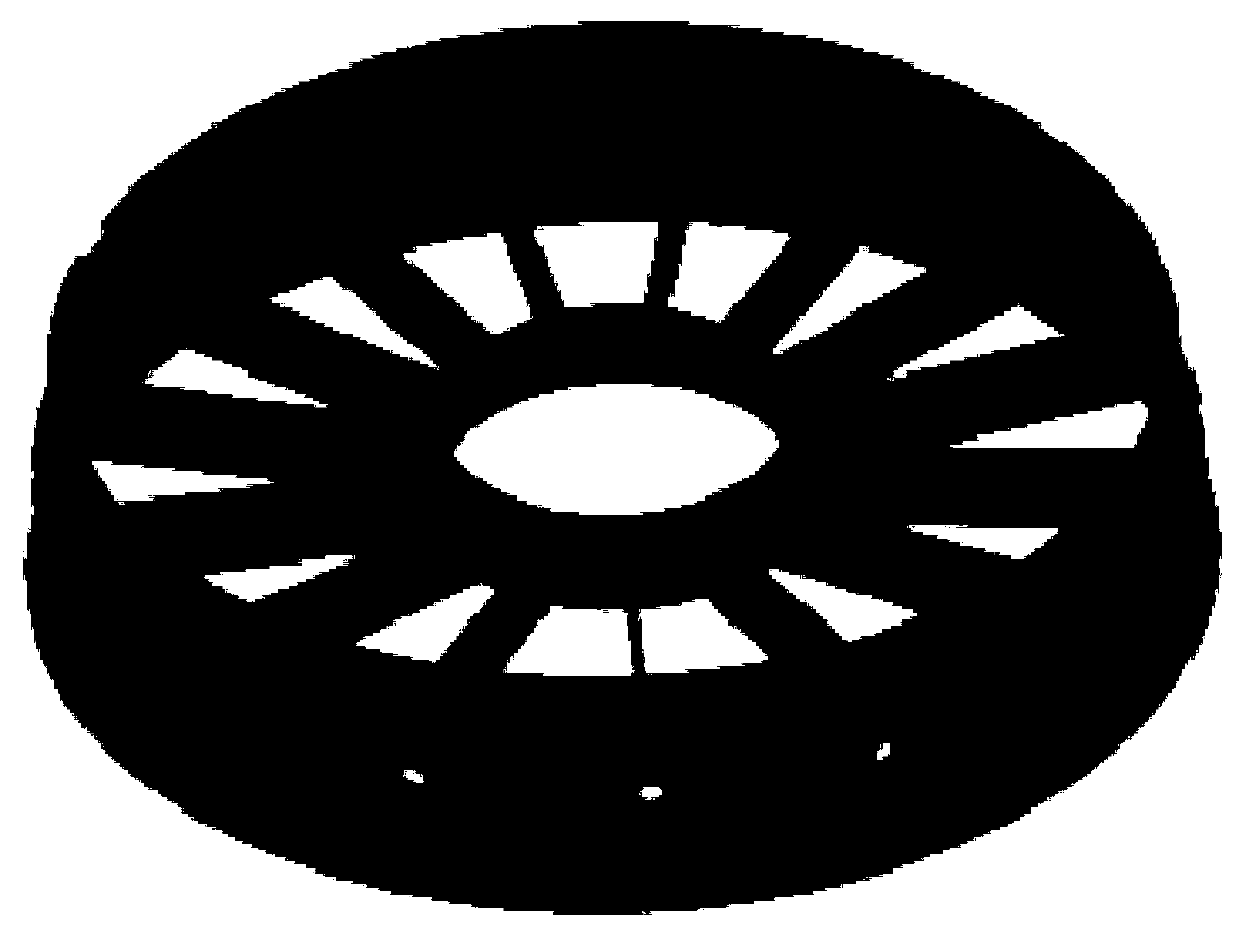

[0031] A laser welding method for the narrow space of the casing, the schematic diagram of the three-dimensional model of the casing is as follows figure 2 shown, including the following steps:

[0032] Step 1, preparation before welding:

[0033] Before welding, use acetone to remove oil stains on the joint section of the part and the 8-12mm area on both sides of the joint;

[0034] Step 2, assembly tack welding:

[0035] Assemble the fixed support plate, the outer casing and the front section of the inner ring on the welding tool, and use argon arc welding to position the front section of the inner ring and the fixed support plate to ensure that the matching gap is ≤ 0.1mm;

[0037] (1) Using robot fiber laser welding equipment with galvanometer laser swing welding head, the focal length of the laser head is more than 300mm, to ensure the accessibility of the laser, so that the end of the welding seam reaches the bottom of the surface to b...

Embodiment 2

[0042] A laser welding method for the narrow space of the casing, the schematic diagram of the three-dimensional model of the casing is as follows figure 2 shown, including the following steps:

[0043] Step 1, preparation before welding:

[0044] Before welding, use acetone to remove oil stains on the joint section of the part and the 8-12mm area on both sides of the joint;

[0045] Step 2, assembly tack welding:

[0046] Assemble the fixed support plate, the outer casing and the front section of the inner ring on the welding tool, and use argon arc welding to position the front section of the inner ring and the fixed support plate to ensure that the matching gap is ≤ 0.1mm;

[0048] (1) Using robot fiber laser welding equipment with galvanometer laser swing welding head, the focal length of the laser head is more than 300mm, to ensure the accessibility of the laser, so that the end of the welding seam reaches the bottom of the surface to b...

Embodiment 3

[0053] A laser welding method for the narrow space of the casing, the schematic diagram of the three-dimensional model of the casing is as follows figure 2 shown, including the following steps:

[0054] Step 1, preparation before welding:

[0055] Before welding, use acetone to remove oil stains on the joint section of the part and the 8-12mm area on both sides of the joint;

[0056] Step 2, assembly tack welding:

[0057] Assemble the fixed support plate, the outer casing and the front section of the inner ring on the welding tool, and use argon arc welding to position the front section of the inner ring and the fixed support plate to ensure that the matching gap is ≤ 0.1mm;

[0059] (1) Using robot fiber laser welding equipment with galvanometer laser swing welding head, the focal length of the laser head is more than 300mm, to ensure the accessibility of the laser, so that the end of the welding seam reaches the bottom of the surface to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com