Servo motor

A servo motor and magnet technology, applied in the field of servo motors, can solve the problems of easy wear and tear of the stator shaft, high running noise, imperfect precision, etc., and achieve the effect of reducing the heating coefficient, eliminating dead spots, and uniform magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

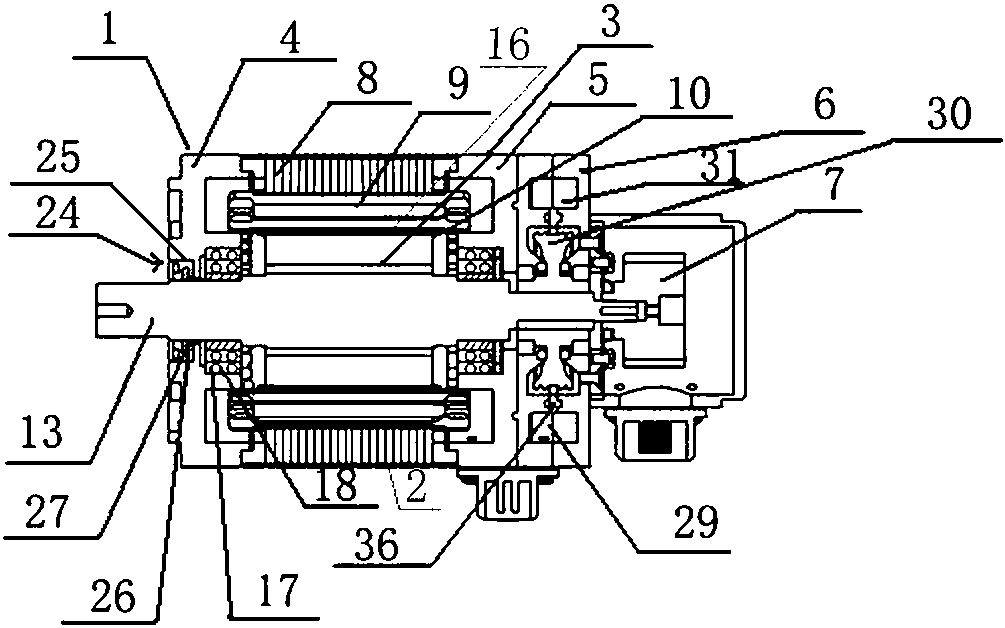

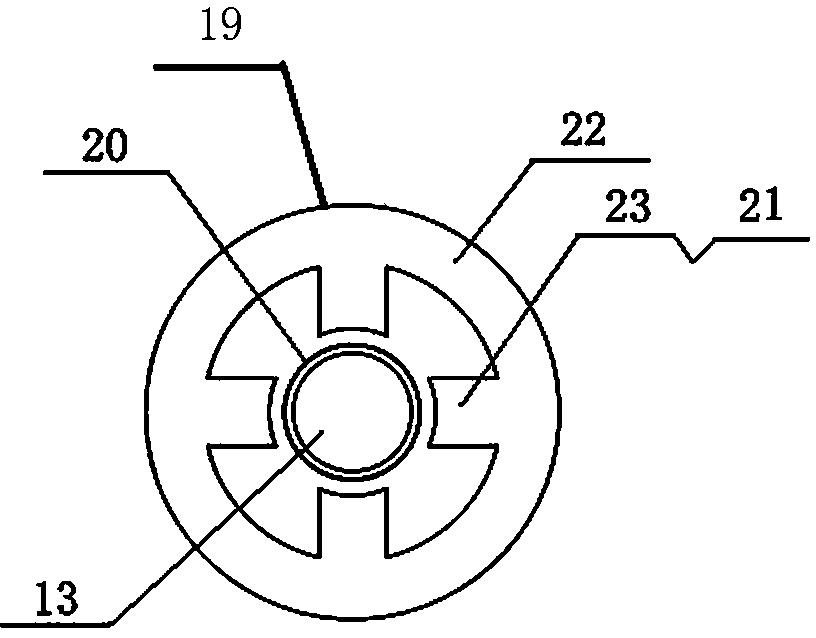

[0031] A servo motor, comprising a motor housing 1, a stator 2, a rotor 3, a front end cover 4, a rear end cover 5, a slip magnetic levitation precise start-stop device 6 and an encoder 7, characterized in that:

[0032] The stator 2 is mainly assembled by a stator silicon steel sheet 8 , a stator three-phase short-pitch coil 9 and an anti-off key 10 . The silicon steel sheet 8 is fixed on the inner wall of the motor housing 1 . The stator coil support 11 is provided with a rotary coil slot 12, and the three-phase short-pitch coils 9 of the stator are respectively installed in the corresponding rotary coil slot 12 according to the design requirements, and are insulated by epoxy resin casting.

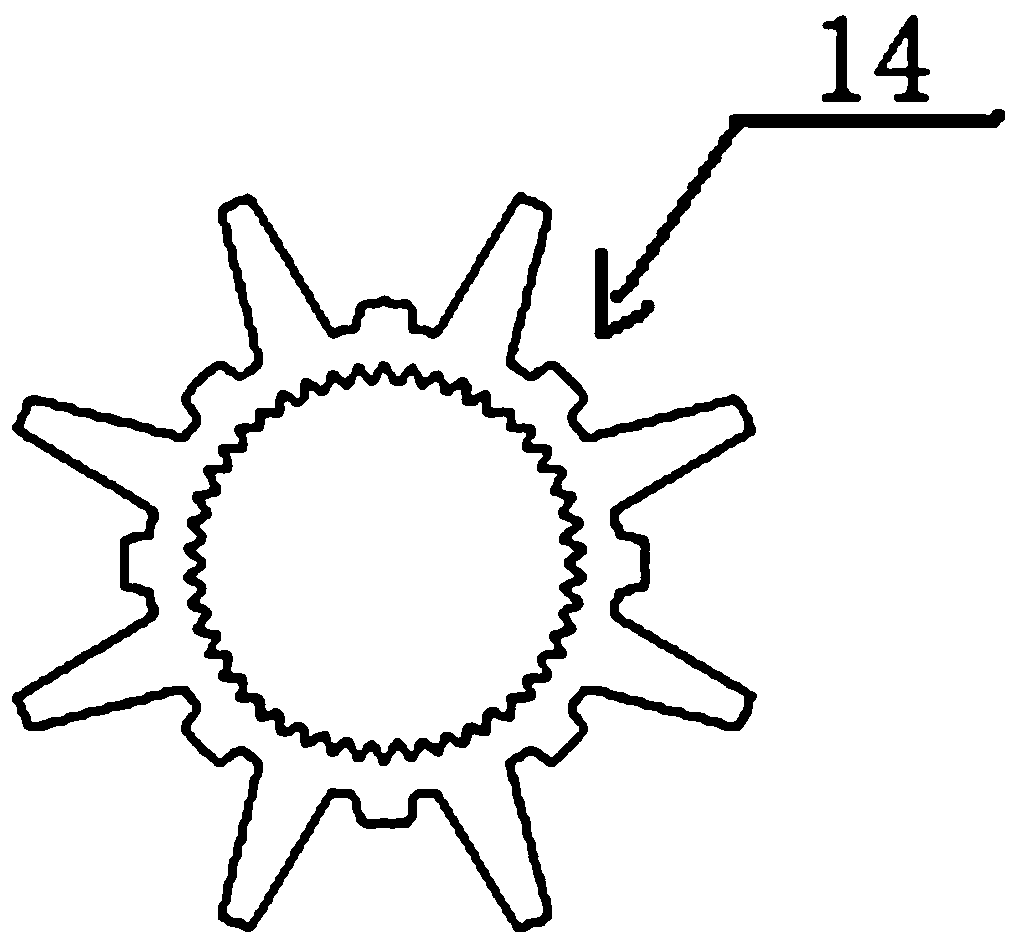

[0033] The rotor 3 is mainly assembled from a main shaft 13, a rotor magnet cage 14, eight pairs of rotor magnets 15, and a magnet engine cover 16. The cross section of the rotor magnetic steel cage 14 is an octagonal star structure; the cross section of the rotor magnetic steel 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com