Cheese-flavored essence and preparation method thereof

A cheese and flavor technology, applied in the field of cheese flavor essence and preparation thereof, can solve the problems of lack of natural aroma and real taste of taste, insufficient aroma intensity, weakened aroma intensity, etc., and achieve easy process control, easy preservation, enhanced flavor and top fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

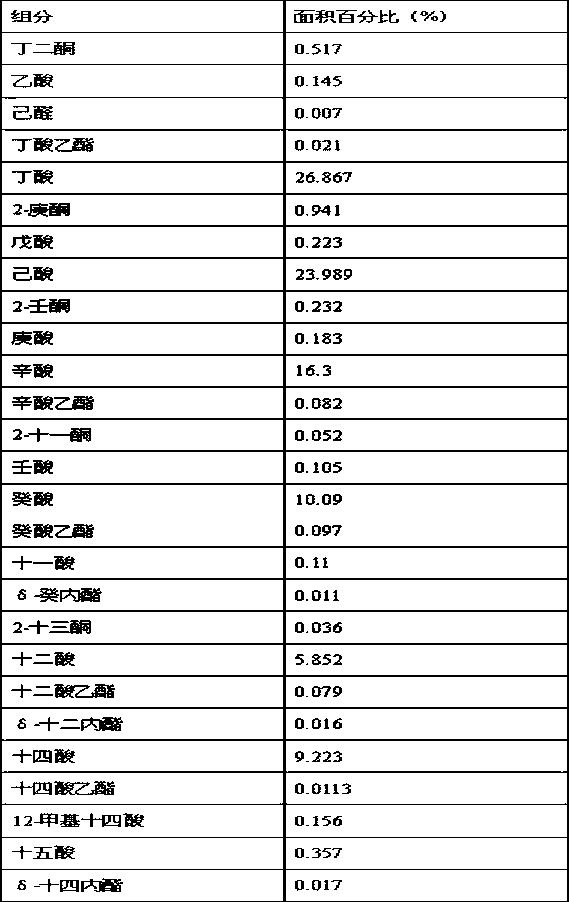

Image

Examples

Embodiment 1

[0024] A cheese flavor flavor, the raw materials of which include 90 parts cheese flavor, 2.5 parts cheese flavor base, 15 parts maltodextrin and 1.5 parts gum arabic in parts by weight;

[0025] [The cheese flavor base is mainly prepared from the following raw materials in parts by weight:

[0026] 0.3 parts of diacetyl, 2 parts of caprylic acid, 0.3 parts of ethyl caprate, 0.25 parts of 2-heptanone, 0.3 parts of 2-nonanone, 0.45 parts of 2-undecone, 0.8 parts of butydecanoic acid, dodecanoic acid 0.25 parts of ethyl ester, 0.5 parts of butyl laurolactone, 0.5 parts of capric acid, 3 parts of butyric acid, 3.5 parts of caproic acid, 87.85 parts of caprylic acid glyceride;

[0027] The cheese flavor is prepared by the following sequence of steps:

[0028] (1) Mix whole milk powder, whey protein powder, New Zealand cream and water in a ratio of 10:10:15:65 by weight, and cut by a high-speed shear at room temperature to obtain a mixed emulsion;

[0029] (2) Heat the above-mentioned mixed...

Embodiment 2

[0037] A cheese flavor flavor, the raw materials of which include 80 parts cheese flavor, 1 part cheese flavor base, 17.5 parts maltodextrin and 2 parts gum arabic by weight;

[0038] The cheese flavor base is mainly prepared from the following raw materials in parts by weight ratio:

[0039] 0.8 part of diketone, 0.2 part of caprylic acid, 0.8 part of ethyl caprate, 0.5 part of 2-heptanone, 0.2 part of 2-nonanone, 0.6 part of 2-undecone, 0.6 part of butydecanoic acid, dodecanoic acid 0.1 part of ethyl ester, 1.5 parts of butyl laurolactone, 0.3 part of capric acid, 1 part of butyric acid, 5 parts of caproic acid, 95 parts of glyceryl caprylate;

[0040] The cheese flavor is prepared by the following sequence of steps:

[0041] (1) Mix whole milk powder, whey protein powder, New Zealand cream and water in a ratio of 10:10:15:65 by weight, and cut by a high-speed shear at room temperature to obtain a mixed emulsion;

[0042] (2) Heat the above-mentioned mixed emulsion to 80-82℃, and hea...

Embodiment 3

[0050] A cheese flavor flavor, the raw materials of which include 85 parts by weight of cheese flavor, 2.5 parts of cheese flavor base, 11 parts of maltodextrin and 1.5 parts of gum arabic;

[0051] The cheese flavor base is mainly prepared from the following raw materials in parts by weight ratio:

[0052] 0.6 parts of diacetyl, 4 parts of octanoic acid, 0.5 parts of ethyl decanoate, 0.1 parts of 2-heptanone, 0.5 parts of 2-nonanone, 0.2 parts of 2-undecone, 1.5 parts of butydecanoic acid, dodecanoic acid 0.4 part of ethyl ester, 1 part of butyl laurolactone, 1 part of capric acid, 5 parts of butyric acid, 0.5 part of caproic acid, 65 parts of glyceryl caprylate;

[0053] The cheese flavor is prepared by the following sequence of steps:

[0054] (1) Mix whole milk powder, whey protein powder, New Zealand cream and water in a ratio of 10:10:15:65 by weight, and cut by a high-speed shear at room temperature to obtain a mixed emulsion;

[0055] (2) Heat the above mixed emulsion to 81-83°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com