Two-dimensional MOF/ carbon oxide material composite thin film and its preparation method and application

A composite film and carbon oxide technology, which is applied in radioactive purification, nuclear engineering, etc., can solve the problems of forming graphite flakes and easy stacking of graphene, and achieve strong adsorption capacity, strong repeatability, and high adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

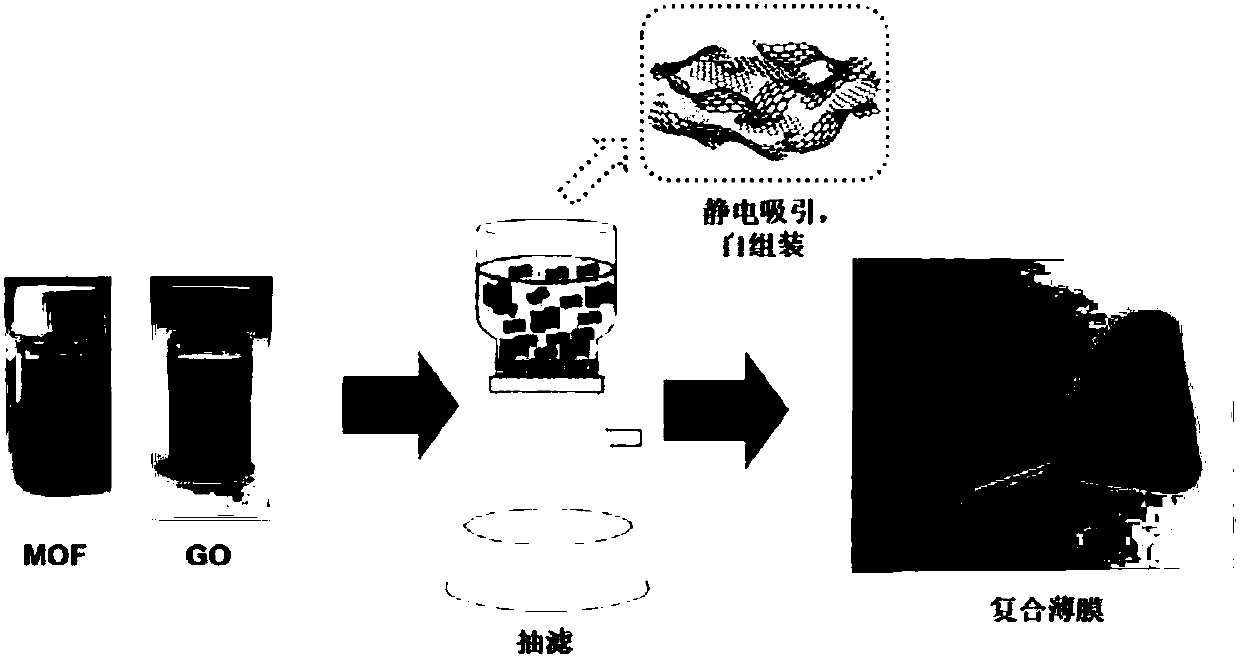

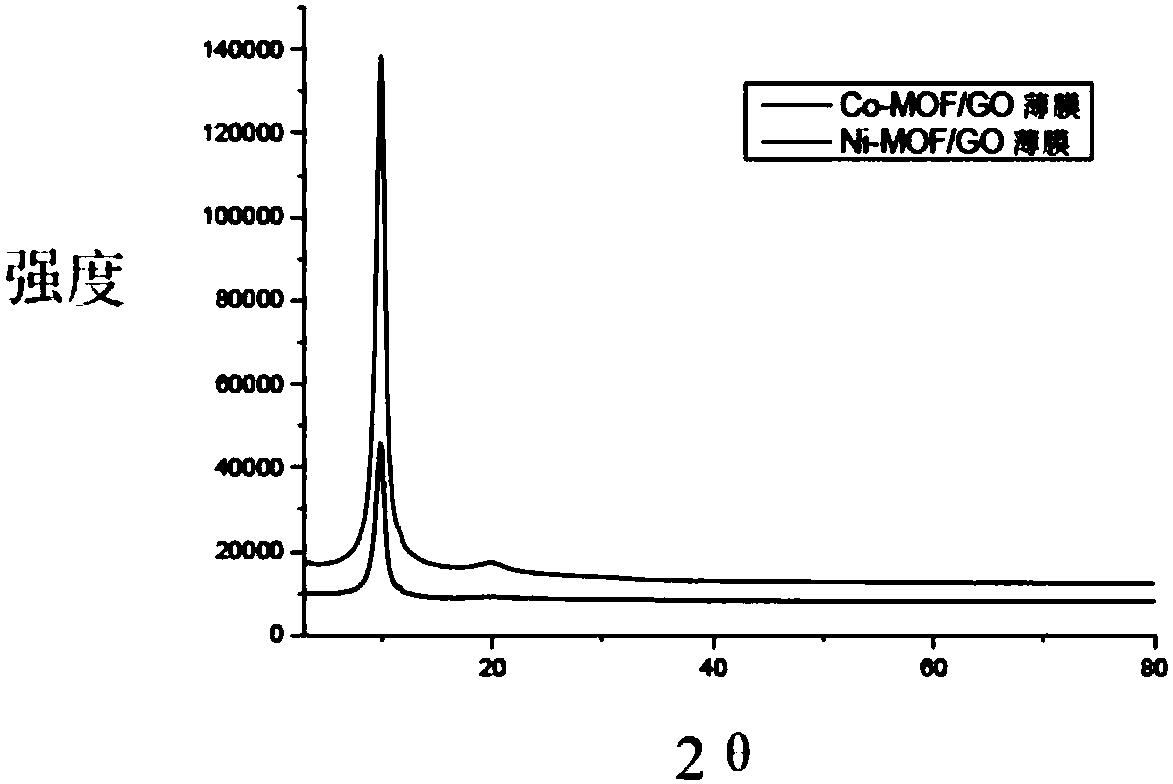

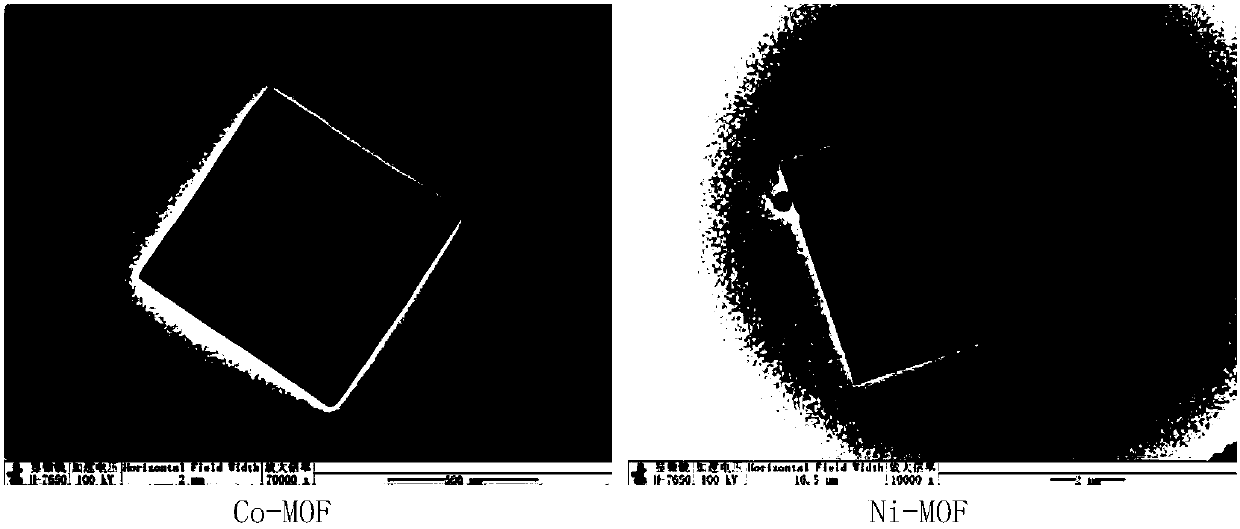

[0075] This example involves the preparation of Co-MOF / GO composite thin films.

[0076] Preparation of GO

[0077] 20g of expandable graphite was placed in a crucible, and the crucible was placed in a muffle furnace at 1100°C for 15 seconds to rapidly expand to obtain expanded graphite. Weigh 1g of expanded graphite and place it in an 800ml beaker. Use a graduated cylinder to measure 200ml of concentrated sulfuric acid and add it to the beaker containing the expanded graphite. Put a rotor in the beaker and stir at room temperature for 10 minutes to make it evenly mixed. Then, weigh 10 g of potassium permanganate, slowly add it into the beaker, then put the beaker into a water bath, heat the liquid in the beaker to 60° C. and keep it warm for 24 hours for oxidation. After oxidation, 25ml of hydrogen peroxide was added at 0°C to react excess potassium permanganate, and then 25ml of concentrated hydrochloric acid was added. Finally, the reaction product was centrifuged and was...

Embodiment 2

[0084] This example involves the preparation of Ni-MOF / GO composite thin films.

[0085] According to the process of Example 1, Ni-MOF was prepared by using 0.015 mmol of Ni(NO3)2·6H2O as the precursor solution, and Ni-MOF / GO was obtained by suction filtration with GO for 24 hours, and the prepared composite Thin film materials are characterized by a series of morphology and structure.

Embodiment 3

[0087] This example relates to the preparation of Mn-MOF / GO composite thin films.

[0088] According to embodiment 1 process, with the Mn of 0.015mmol (NO 3 ) 2 ·6H 2 O is the precursor solution to prepare Mn-MOF, and after 24 hours of suction filtration with GO, the Mn-MOF / GO composite film can be obtained, and a series of morphological and structural characterizations of the prepared composite film material are performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com