Steam reheating system for waste incineration boiler

A waste incineration and heating system technology, applied in the field of waste incinerator heating equipment, can solve the problems of weak reheat steam cooling capacity, high temperature corrosion of reheater, and unguaranteed service life, so as to reduce investment cost and floor area, Improve heat transfer efficiency and reduce high temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

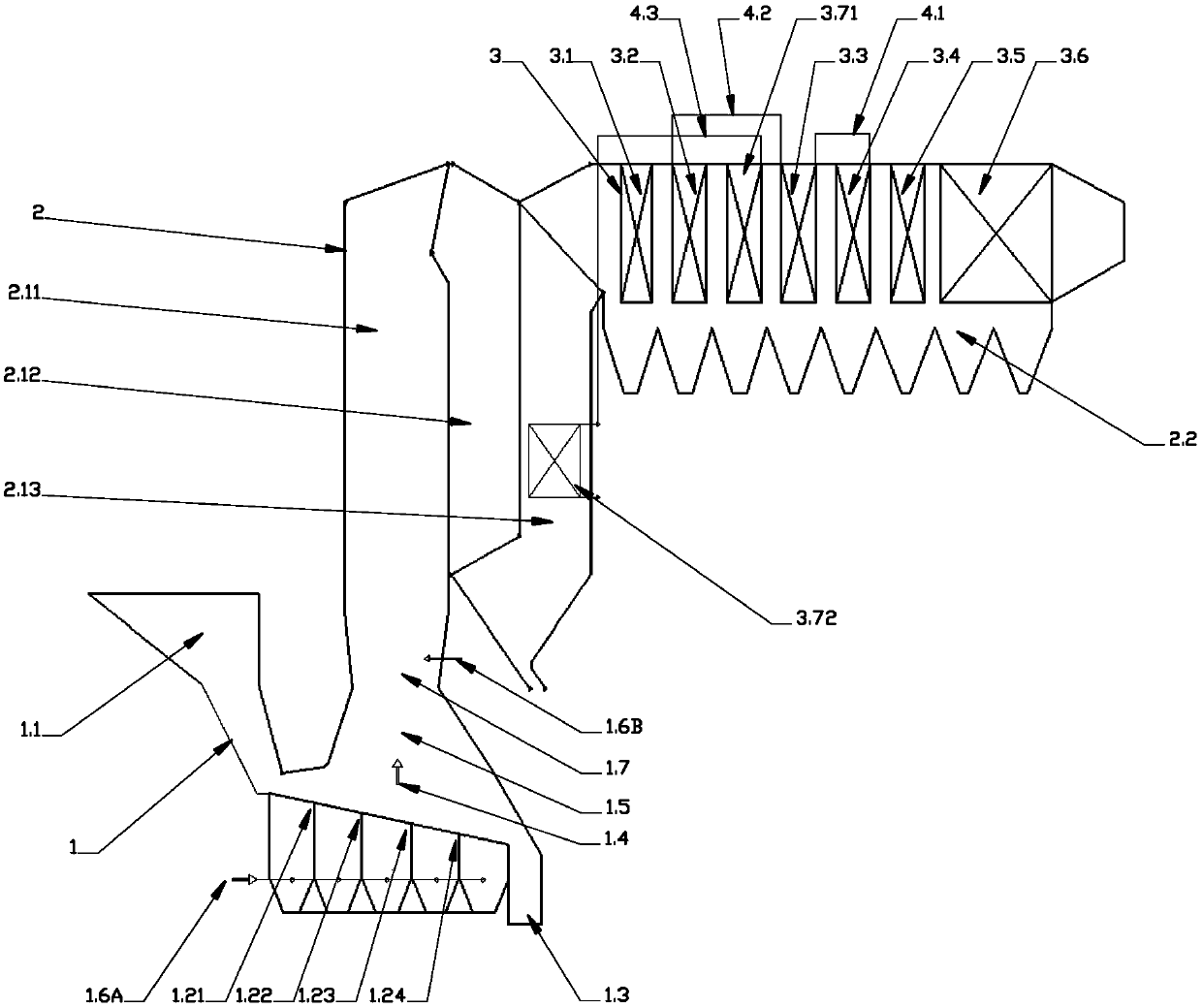

[0027] figure 1 It is a schematic diagram of the structural arrangement of an embodiment proposed by the present invention. As shown in the figure, a waste incineration boiler superheater system mainly includes a grate 1.2, a furnace 1.5, a flue 2 and a heat receiver 3. The grate 1.2 includes a drying section 1.21, a pyrolysis section 1.22, a combustion section 1.23, and a burnout section 1.24, the flue 2 includes the first vertical flue 2.11, the second vertical flue 2.12, the third vertical flue 2.13 and the horizontal flue 2.2, and the heat receiver 3 includes the primary evaporator 3.1, the third superheater 3.2, the second Stage superheater 3.3, stage one superheater 3.4, stage two evaporator 3.5, and economizer group 3.6, arrange stage one evaporator 3.1, stage three superheater 3.2, stage two Superheater 3.3, primary superheater 3.4, secondary evaporator 3.5 and economizer group 3.6.

[0028] figure 1 It shows that the furnace body 1 mainly includes the grate 1.2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com