Technology for pretreating wastewater containing phenols through resin adsorption method

A resin adsorption and pretreatment technology, applied in adsorption water/sewage treatment, filtration treatment, special treatment targets, etc., can solve the problems of non-compliance with discharge standards, long treatment time, short service cycle, etc., and achieve easy desorption and regeneration. , low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

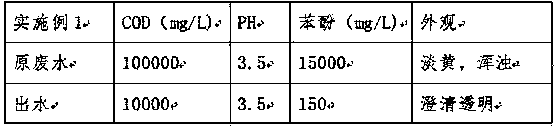

Embodiment 1

[0024] In this embodiment, the resin adsorption method pretreatment process of phenol-containing wastewater includes the following steps:

[0025] (1) Send the wastewater with a pH value of 3.5, a COD content of 100,000 mg / L, and a phenol content of 15,000 mg / L to the pre-stage raw wastewater tank through the filter;

[0026] (2) The waste water entering the former waste water tank is continuously fed into the resin adsorption tower through the adsorption circulation pump, and the flow rate is controlled to 1m 3 / h; the phenol-containing wastewater entering the resin adsorption tower is continuously adsorbed by the XDM-1G resin column in the adsorption tower through two stages of continuous adsorption, and the phenol in the wastewater is adsorbed on it;

[0027] (3) After the resin is adsorbed, the pretreated wastewater passes through the wastewater pump at a rate of 1m 3 / h flow into the sewage treatment tank;

[0028] (4) After every 10 tons of wastewater is treated, the X...

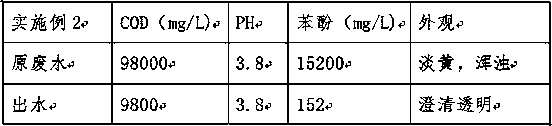

Embodiment 2

[0035] In this embodiment, the resin adsorption method pretreatment process of phenol-containing wastewater includes the following steps:

[0036] (1) Send the wastewater with a pH value of 3.8, a COD content of 98000mg / L, and a phenol content of 15200mg / L to the pre-stage raw wastewater tank through the filter;

[0037] (2) The waste water entering the former waste water tank is continuously fed into the resin adsorption tower through the adsorption circulation pump, and the flow rate is controlled to 2m 3 / h; the phenol-containing wastewater entering the resin adsorption tower is continuously adsorbed by the XDM-1G resin column in the adsorption tower through two stages of continuous adsorption, and the phenol in the wastewater is adsorbed on it;

[0038] (3) After the resin is adsorbed, the pretreated wastewater passes through the wastewater pump at a distance of 3m 3 / h flow into the sewage treatment tank;

[0039] (4) After every 10 tons of wastewater is treated, the XD...

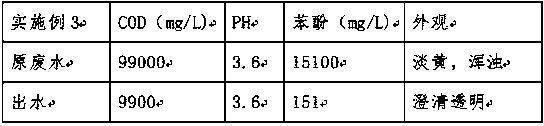

Embodiment 3

[0046] In this embodiment, the resin adsorption method pretreatment process of phenol-containing wastewater includes the following steps:

[0047] (1) Send the wastewater with a pH value of 3.6, a COD content of 99000mg / L, and a phenol content of 15100mg / L to the pre-stage raw wastewater tank through the filter;

[0048] (2) The waste water entering the former waste water tank is continuously fed into the resin adsorption tower through the adsorption circulation pump, and the flow rate is controlled to 2m 3 / h; the phenol-containing wastewater entering the resin adsorption tower is continuously adsorbed by the XDM-1G resin column in the adsorption tower through two stages of continuous adsorption, and the phenol in the wastewater is adsorbed on it;

[0049] (3) After the resin is adsorbed, the pretreated wastewater passes through the wastewater pump at a distance of 3m 3 / h flow into the sewage treatment tank;

[0050] (4) After every 10 tons of wastewater is treated, the XDM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com