Preparation method for graphene-ceramic composite material

A ceramic composite material and ceramic composite technology, applied in the field of graphene composite materials, can solve the problems of unfavorable mixing and dispersion of ceramic powder, increase of process cycle and cost, environmental hazards, etc., and achieve the effect of low cost, optimized performance and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation of graphene ceramic composite material, comprises the steps:

[0039] Step 1, get 10g average particle diameter and be that the magnesium powder of 100 μ m and 90g average particle diameter be the Al of 200nm 2 o 3 The powder is ball milled for 1 hour and mixed evenly;

[0040] Step 2, place the uniformly mixed raw material powder in the graphite mold of the combustion reaction device, in the carbon dioxide gas of 0.5MPa, use a 50A tungsten coil to induce the self-propagating combustion reaction between the magnesium powder in the raw material and carbon dioxide, and cool the device Finally, a gray-black graphene ceramic composite powder is obtained.

[0041] Step 3: Using spark plasma sintering, the graphene ceramic composite powder is sintered under a pressure of 60 MPa at 1500° C. for 30 minutes in vacuum to obtain a graphene ceramic composite material with a diameter of 30 mm and a thickness of 3 mm.

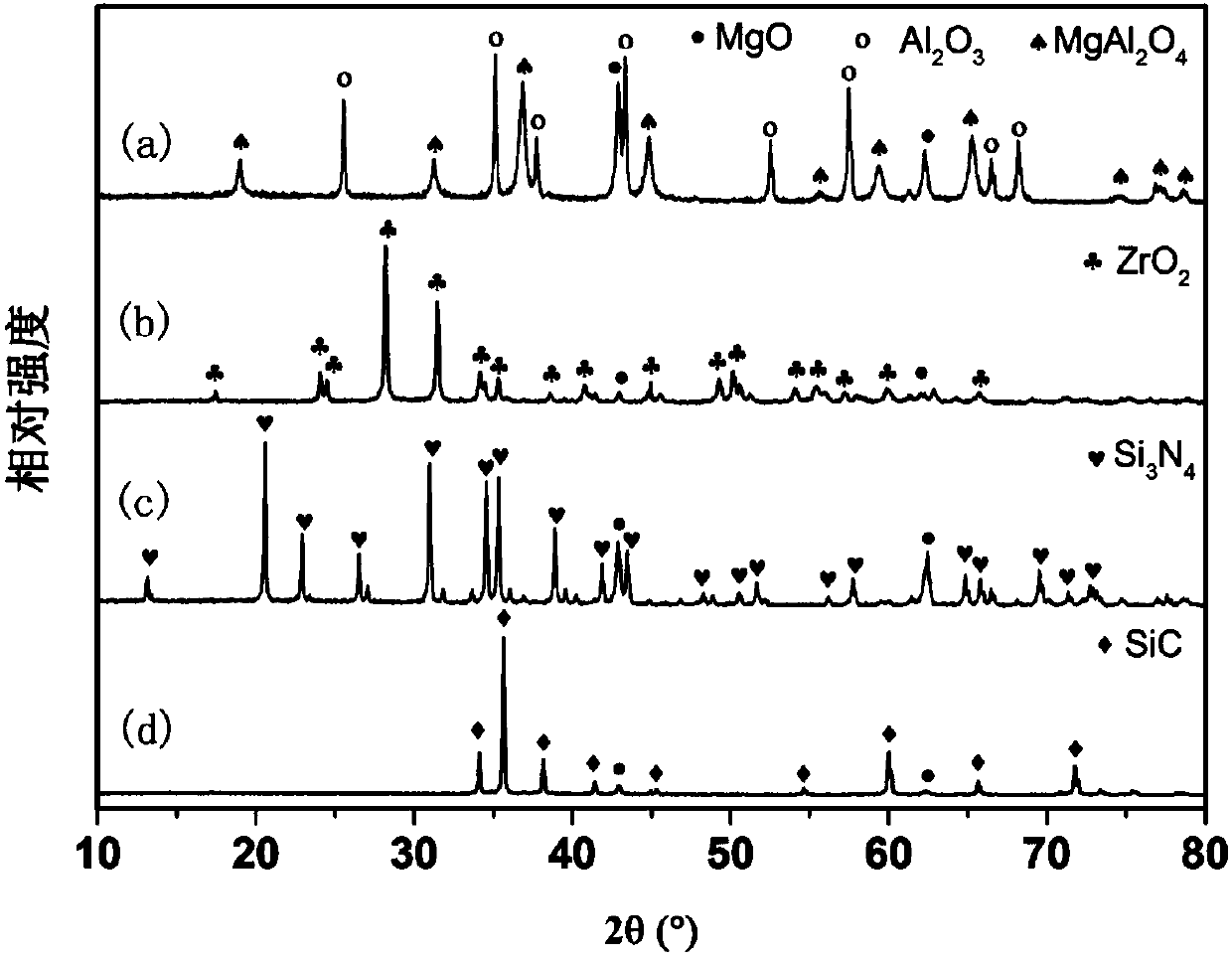

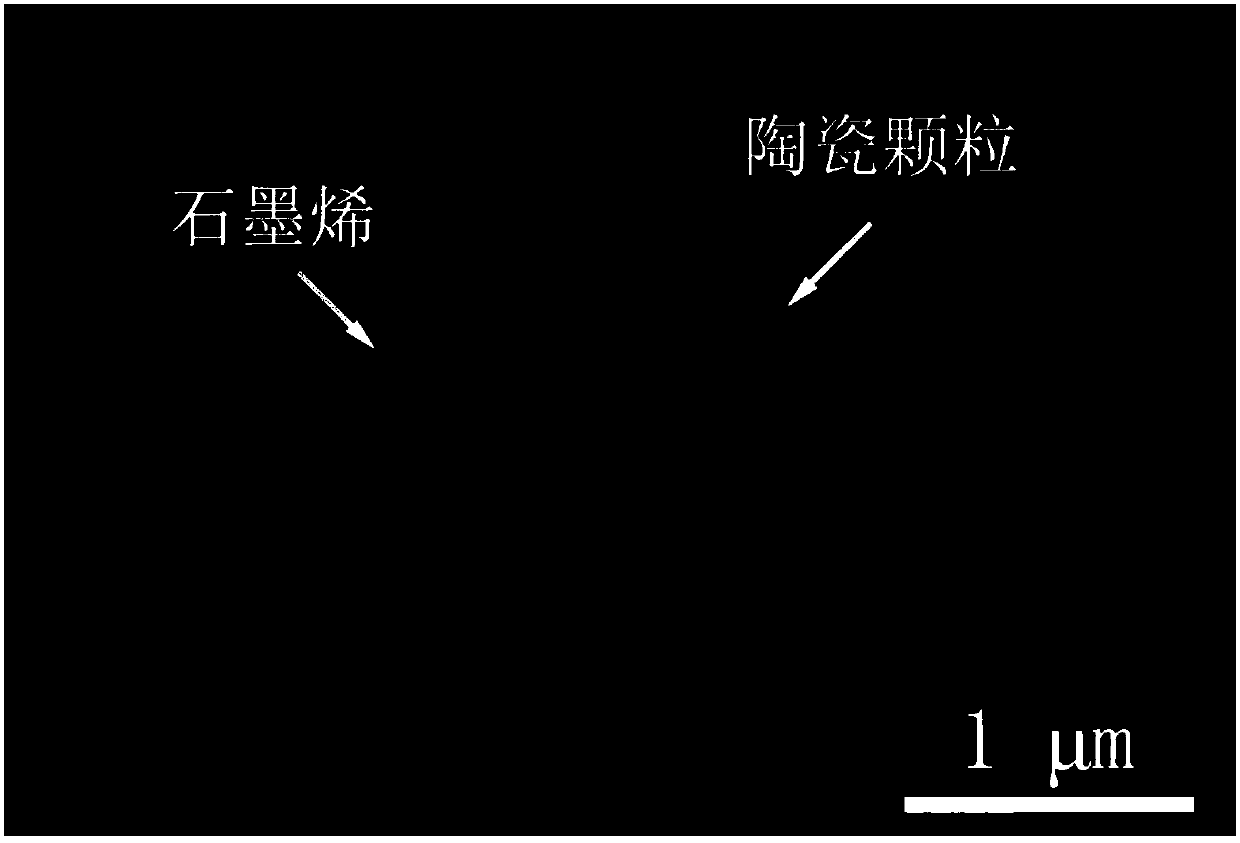

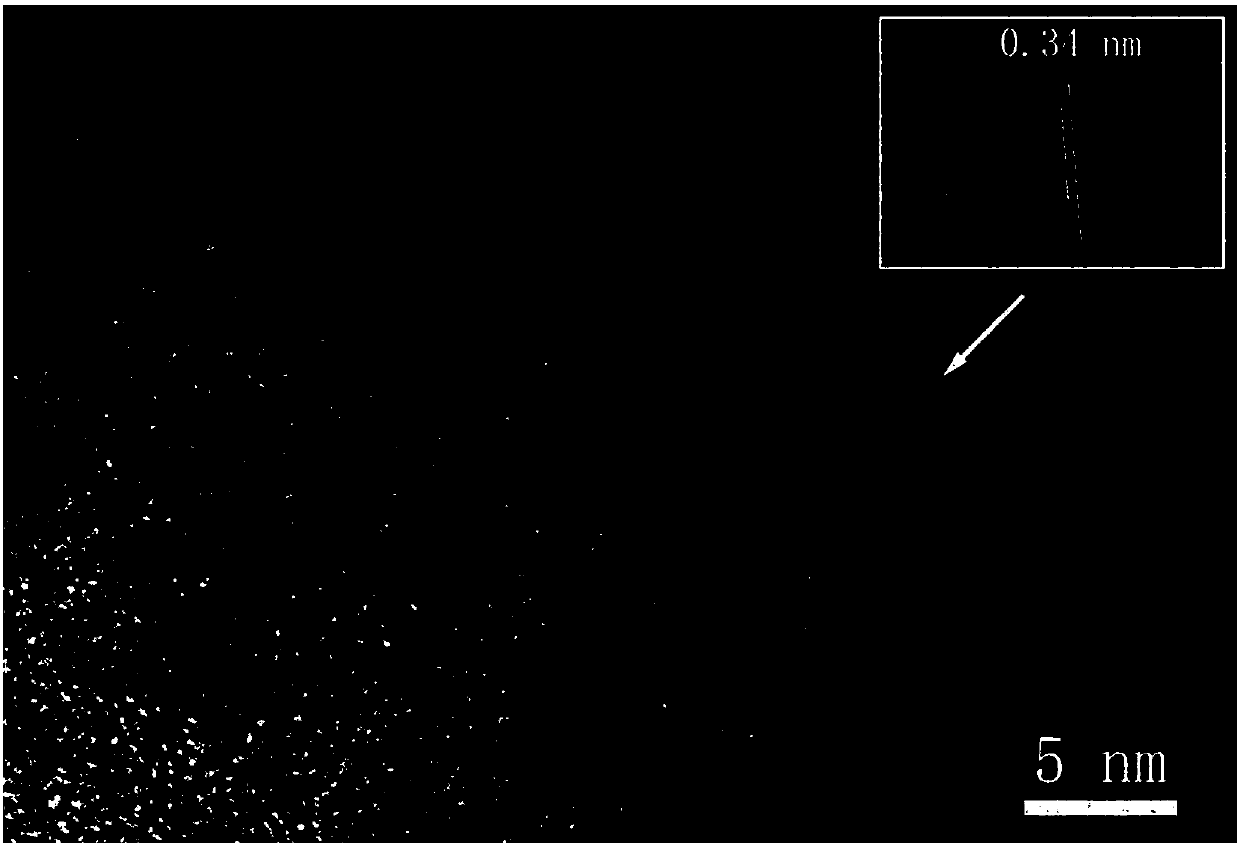

[0042] figure 1 Middle (a) is the X-ra...

Embodiment 2

[0048] A kind of preparation of graphene ceramic composite material, comprises the steps:

[0049] Step 1, take 9g of magnesium powder with an average particle size of 45 μm and 9.69g of MgO powder with an average particle size of 100nm and 62.31g of Al with an average particle size of 200nm 2 o 3 The powder is ball milled for 1 hour and mixed evenly;

[0050] Step 2, place the uniformly mixed raw material powder in the graphite mold of the combustion reaction device, in the carbon dioxide gas of 1.0MPa, use a 40A tungsten coil to induce the self-propagating combustion reaction between the magnesium powder in the raw material and carbon dioxide, and cool the device Finally, a gray-black graphene ceramic composite powder is obtained.

[0051] Step 3: Using spark plasma sintering, the graphene ceramic composite powder is sintered under a pressure of 60 MPa at 1400° C. for 20 minutes in vacuum to obtain a graphene ceramic composite material with a diameter of 10 mm and a thickn...

Embodiment 3

[0057] A kind of preparation of graphene ceramic composite material, comprises the steps:

[0058] Step 1, getting 10g average particle diameter is that the magnesium powder of 25 μm and 68g average particle diameter are the ZrO of 500nm 2 Powder and 2g of Y with an average particle size of 50nm 2 o 3 The powder is ball milled for 1 hour and mixed evenly;

[0059] Step 2, place the uniformly mixed raw material powder in the graphite mold of the combustion reaction device, in the carbon dioxide gas of 2.0MPa, use a 30A tungsten coil to induce the self-propagating combustion reaction between the magnesium powder in the raw material and carbon dioxide, and cool the device Finally, a gray-black graphene ceramic composite powder is obtained.

[0060] Step 3: Using pressureless sintering, the graphene ceramic composite powder is formed by cold isostatic pressing under a pressure of 200 MPa, and then sintered at 1500° C. for 4 hours under vacuum to obtain a graphene ceramic compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com