Cephalosporin C mushroom dreg treatment method, hydrolysate and application thereof

A technology of cephalosporin and treatment method, which is applied in the field of microbial fermentation, can solve the problems that are difficult to meet large-scale industrial application and the amount of bacteria residue is small, and achieve the effects of being suitable for large-scale industrial application, increasing production, and solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

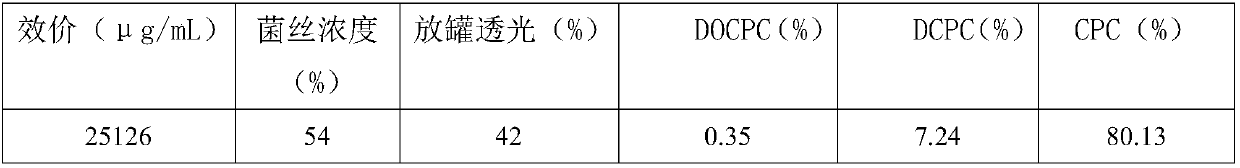

Embodiment 1

[0033] Embodiment 1 bacterial residue processing method of the present invention:

[0034] 1. Mushroom residue pretreatment method:

[0035] Collect the cephalosporin C bacteria residue, add water and stir to dilute to a water content of 40%, then hydrolyze. Adjust the pH to 7.0 to obtain the hydrolyzate of the fungus residue.

[0036] 2. Fermentation method

[0037] (1) Preparation of primary seeds

[0038] Take the slant of the Cephalosporium acremonium eggplant bottle with the preservation number ATCC36225, and prepare a 25% (mg / mL) bacterial suspension. Inoculate into the seed medium according to the inoculum amount of 1%, and cultivate at 27° C. for 50 h at a pH of 7.0.

[0039] Primary seed medium: 20g corn steep liquor, 35mL soybean oil, 13g glucose, 10g sucrose, 0.5g defoamer, 1g calcium carbonate.

[0040] (2) Preparation of secondary seeds

[0041] The primary seeds were inoculated in the medium of the secondary seeds according to 8% inoculum amount, and cultur...

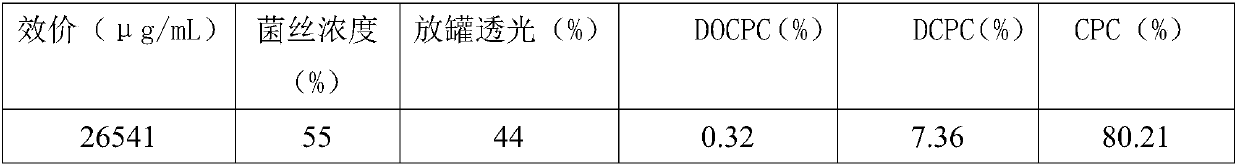

Embodiment 2

[0056] Embodiment 2 Cephalosporin C fermentation method of the present invention

[0057] 1. Mushroom residue pretreatment method:

[0058] Collect cephalosporin C bacteria residue, add water and stir to dilute to water content of 35%, then hydrolyze. , to obtain the hydrolyzate of the fungus slag.

[0059] 2. Fermentation method

[0060] (1) Preparation of primary seeds

[0061] Take the slant of the Cephalosporium acremonium eggplant bottle with the preservation number ATCC36225, and prepare a 25% (mg / mL) bacterial suspension. Inoculate into the seed medium according to the inoculum amount of 1%, and cultivate at 27° C. for 50 h at a pH of 7.0.

[0062] Primary seed medium: 20g corn steep liquor, 35mL soybean oil, 13g glucose, 10g sucrose, 0.5g defoamer, 1g calcium carbonate.

[0063] (2) Preparation of secondary seeds

[0064] The primary seeds were inoculated in the medium of the secondary seeds according to 8% inoculum amount, and cultured at 27° C. for 50 hours at a ...

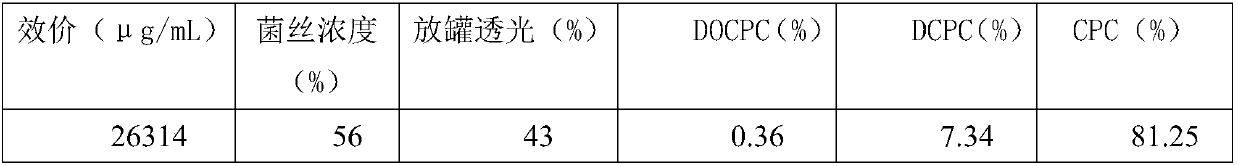

Embodiment 3

[0079] Embodiment 3 The method of fermentative production cephalosporin C of the present invention

[0080] 1. Mushroom residue pretreatment method:

[0081] Collect cephalosporin C bacteria residue, add water and stir to dilute to water content of 35%, then hydrolyze. , to obtain the hydrolyzate of the fungus slag.

[0082] 2. Fermentation method

[0083] (1) Preparation of primary seeds

[0084] Take the slant of the Cephalosporium acremonium eggplant bottle with the preservation number ATCC36225, and prepare a 25% (mg / mL) bacterial suspension. Inoculate into the seed medium according to the inoculum amount of 1%, and cultivate at 27° C. for 50 h at a pH of 7.0.

[0085] Primary seed medium: 20g corn steep liquor, 35mL soybean oil, 13g glucose, 10g sucrose, 0.5g defoamer, 1g calcium carbonate.

[0086] (2) Preparation of secondary seeds

[0087] The primary seeds were inoculated in the medium of the secondary seeds according to 8% inoculum amount, and cultured at 27° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com