Distributing method of titanium alloy with high niobium content

A titanium alloy and cloth technology, applied in the field of titanium alloy material processing, can solve the problems of high cost and low efficiency, and achieve the effect of reducing raw material cost, improving production efficiency and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

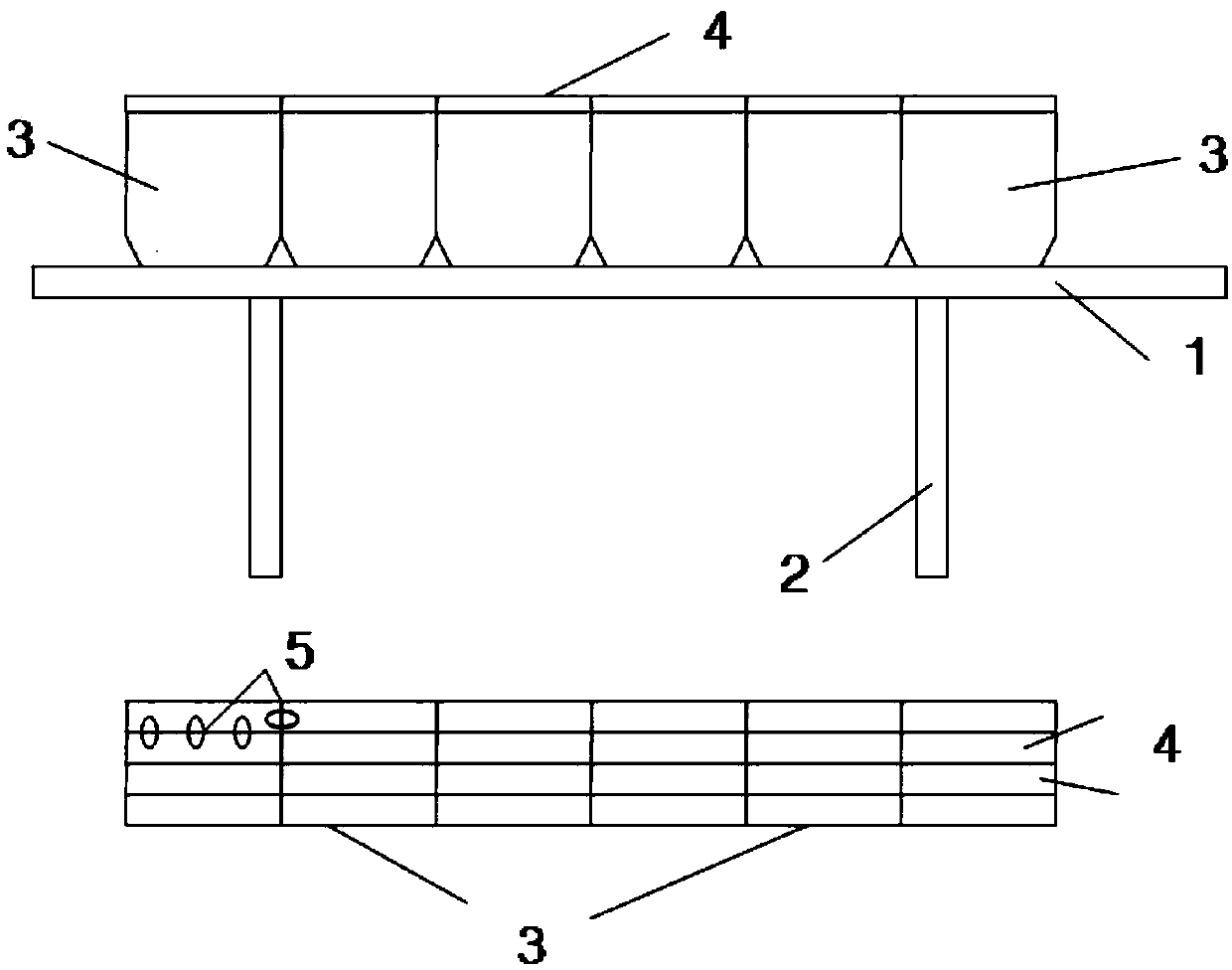

[0022] Use the present invention to distribute Ti-25Nb-25Zr titanium alloy: place the electrode blocks with a single weight of 70kg on the welding platform in sequence, weigh 17.5kg of niobium bars, the thickness of the niobium bars is 3mm, the length is 275mm, and the width is 15mm. Wipe the surface of the niobium bar with ethanol, and then spread the clean niobium bar 3 on the upper surface of the electrode block; then use plasma welding technology to weld the niobium bar, the welding current is 500A, the voltage is 20V, and the number of welding points 5 in the length direction is 3, and the width 1 direction, use argon protection, argon protection time for a single welding spot is 40s, argon flow rate is 4-6L / min, finally, place the same number of electrode blocks on the upper part of the welded niobium bar, and weld them with plasma welding technology , Lower electrode block, welding current 480A, voltage 20V, protection time 60s, argon gas flow 4-6L / min, finally, put the ...

Embodiment 2

[0024] Use the present invention to distribute Ti-13Nb-13Zr titanium alloy: place the electrode blocks with a unit weight of 70kg on the welding platform in sequence, weigh 9.1kg of niobium bars, the thickness of the niobium bars is 3mm, the length is 275mm, and the width is 15mm. Wipe the surface of the niobium bar with ethanol, and then spread the clean niobium bar 4 on the upper surface of the electrode block; then use plasma welding technology to weld the niobium bar, the welding current is 500A, the voltage is 20V, and the number of welding spots 5 in the length direction is 3, and the width 1 direction, protected by an argon protective cover, the argon protection time of a single welding spot is 40s, the argon flow rate is 4-6L / min, finally, the same number of electrode blocks are placed on the upper part of the welded niobium bar, and the plasma welding technology Weld the upper and lower electrode blocks, the welding current is 480A, the voltage is 20V, the protection t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com