A kind of semi-solid indirect extrusion casting molding method of magnesium matrix composite material

A technology of squeeze casting and composite materials, which is applied in the field of semi-solid indirect squeeze casting of magnesium-based composite materials, which can solve the problems of poor oxidation resistance, uneven distribution of reinforced particles, and poor creep resistance at high temperatures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

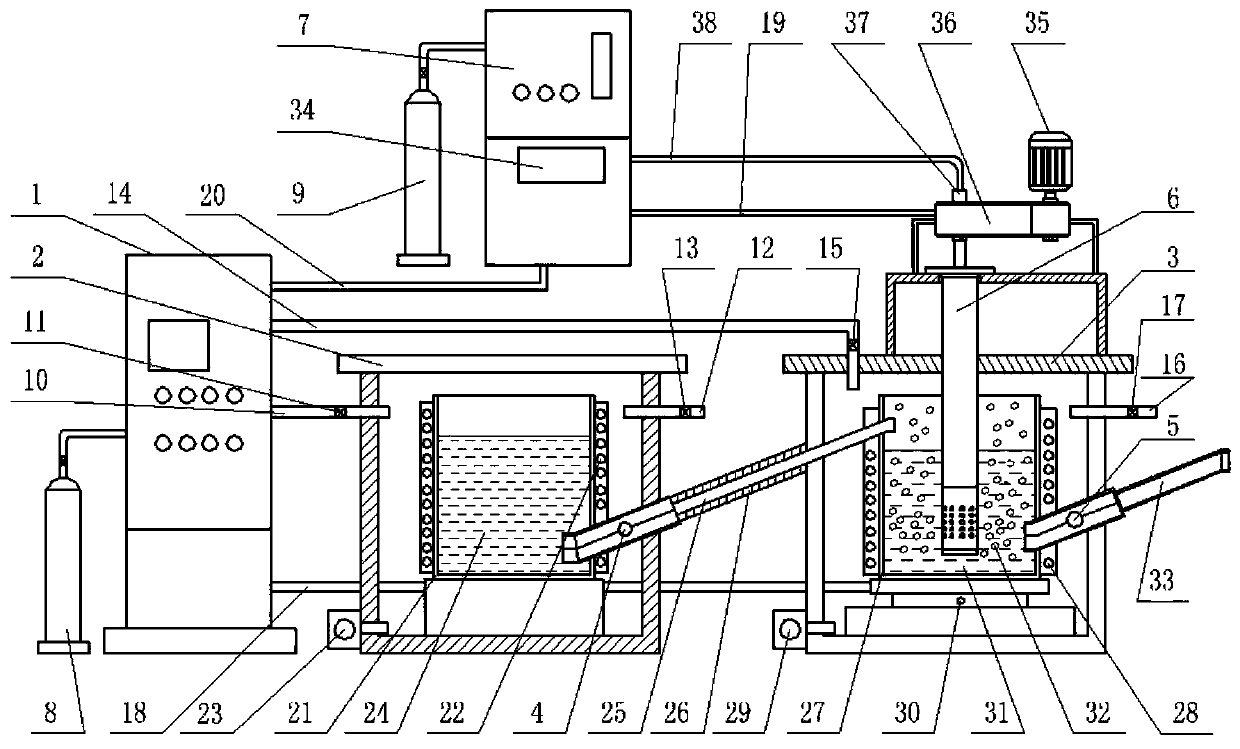

[0062] The present invention will be further described below in conjunction with accompanying drawing:

[0063] figure 1 As shown, it is a state diagram for the preparation of the semi-solid alloy melt of the magnesium-based composite material. The position and connection relationship of each part must be correct and the installation should be firm;

[0064] The whole set of preparation equipment is mainly composed of the main control cabinet 1, the vacuum atmosphere melting furnace 2, the rotary jet stirring furnace 3, the vacuum atmosphere melting furnace electromagnetic pump 4, the rotary jet stirring furnace electromagnetic pump 5, the rotary jet stirring device 6, and the rotary jet stirring device controller 7 composition;

[0065] The main control cabinet 1 controls the vacuum atmosphere melting furnace 2, the rotary jet stirring furnace 3, the vacuum atmosphere melting furnace electromagnetic pump 4, the rotary jet stirring furnace electromagnetic pump 5, the vacuum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com