Planar transformer and manufacturing method

A technology of a planar transformer and a manufacturing method, applied in the field of transformers, can solve problems such as poor performance of planar transformers, and achieve the effects of flexible design method, high frequency and small leakage inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

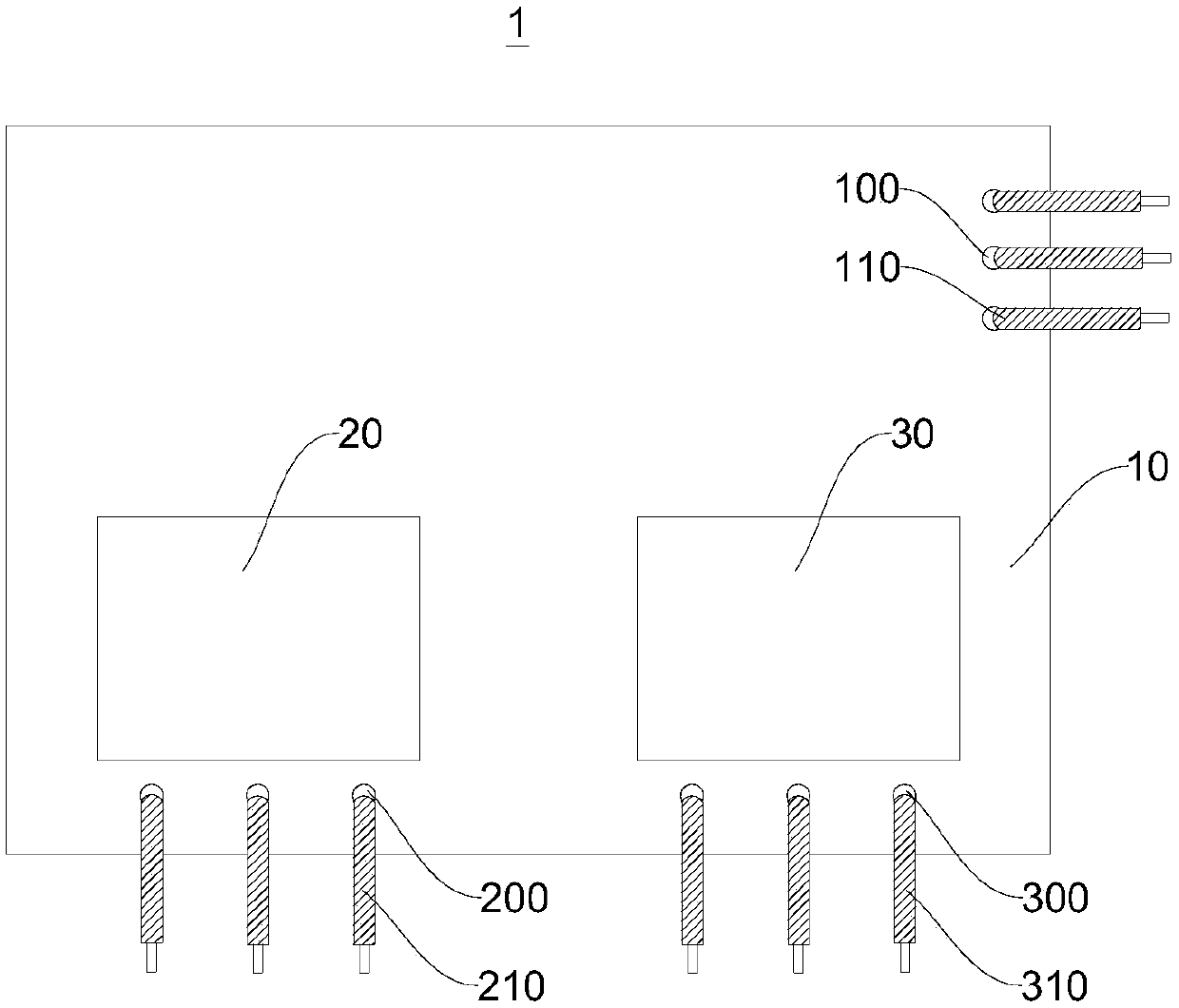

[0035] figure 1 A schematic diagram of the external structure of the planar transformer 1 provided by the embodiment of the present invention is shown. refer to figure 1 , The planar transformer 1 provided by the embodiment of the present invention includes: a PCB board 10 , a first magnetic core 20 , a second magnetic core 30 , an input lead 110 , a first output lead 210 and a second output lead 310 . Wherein, the first magnetic core 20 and the second magnetic core 30 are embedded on the PCB board 10, and the input lead-out hole 100, the first output lead-out hole 200 and the second output lead-out hole 300 are opened through the PCB board 10, and the input lead 110 is soldered On the input lead-out hole 100 , the first output lead 210 is welded on the first output lead-out hole 200 , and the second output lead 310 is welded on the second output lead-out hole 300 .

[0036] The planar transformer 1 can actually be regarded as composed of a first sub-transformer and a second...

no. 2 example

[0047] Figure 6 A flow chart of a method for manufacturing a planar transformer provided by an embodiment of the present invention is shown. See Figure 6 , the method includes:

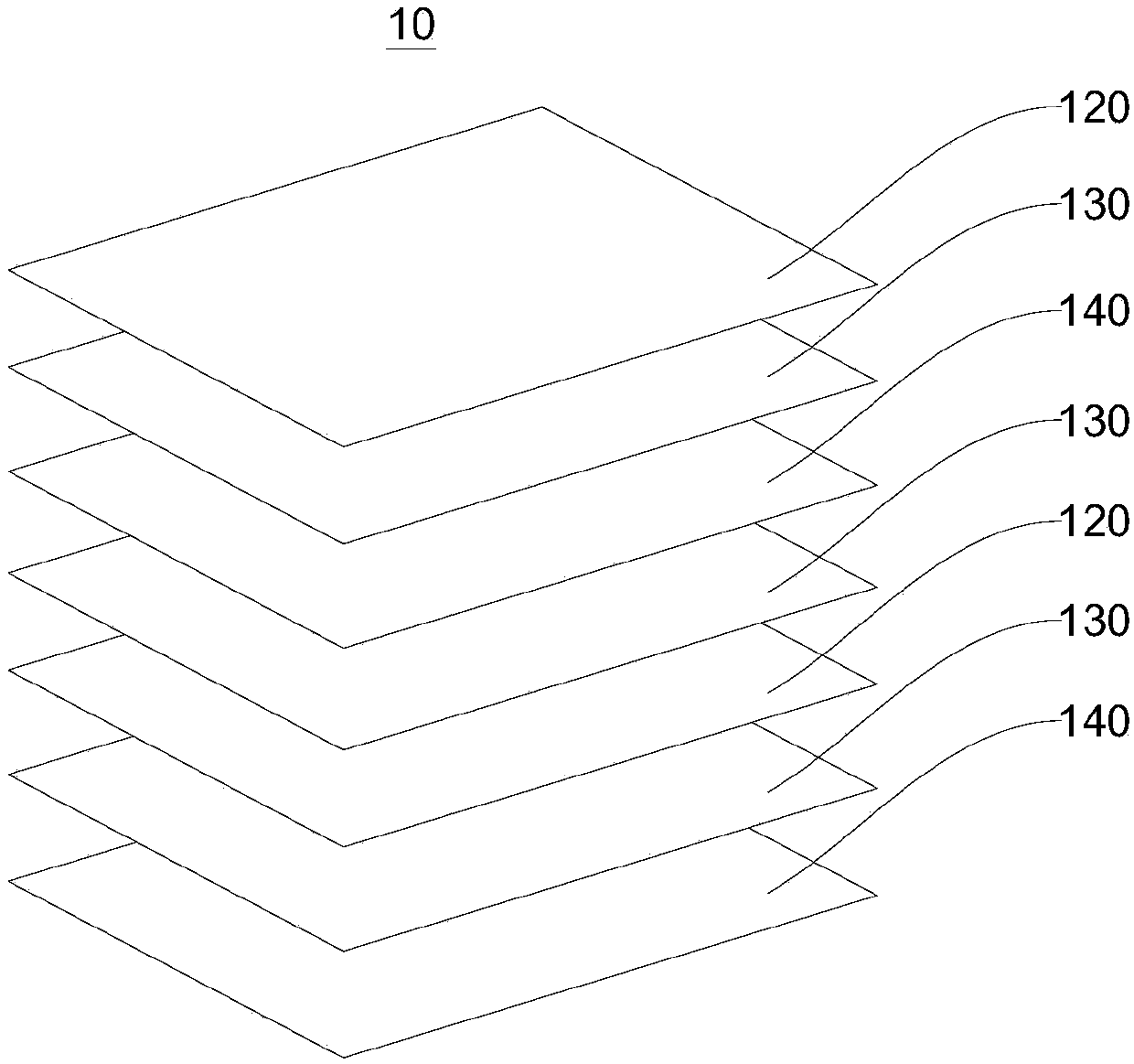

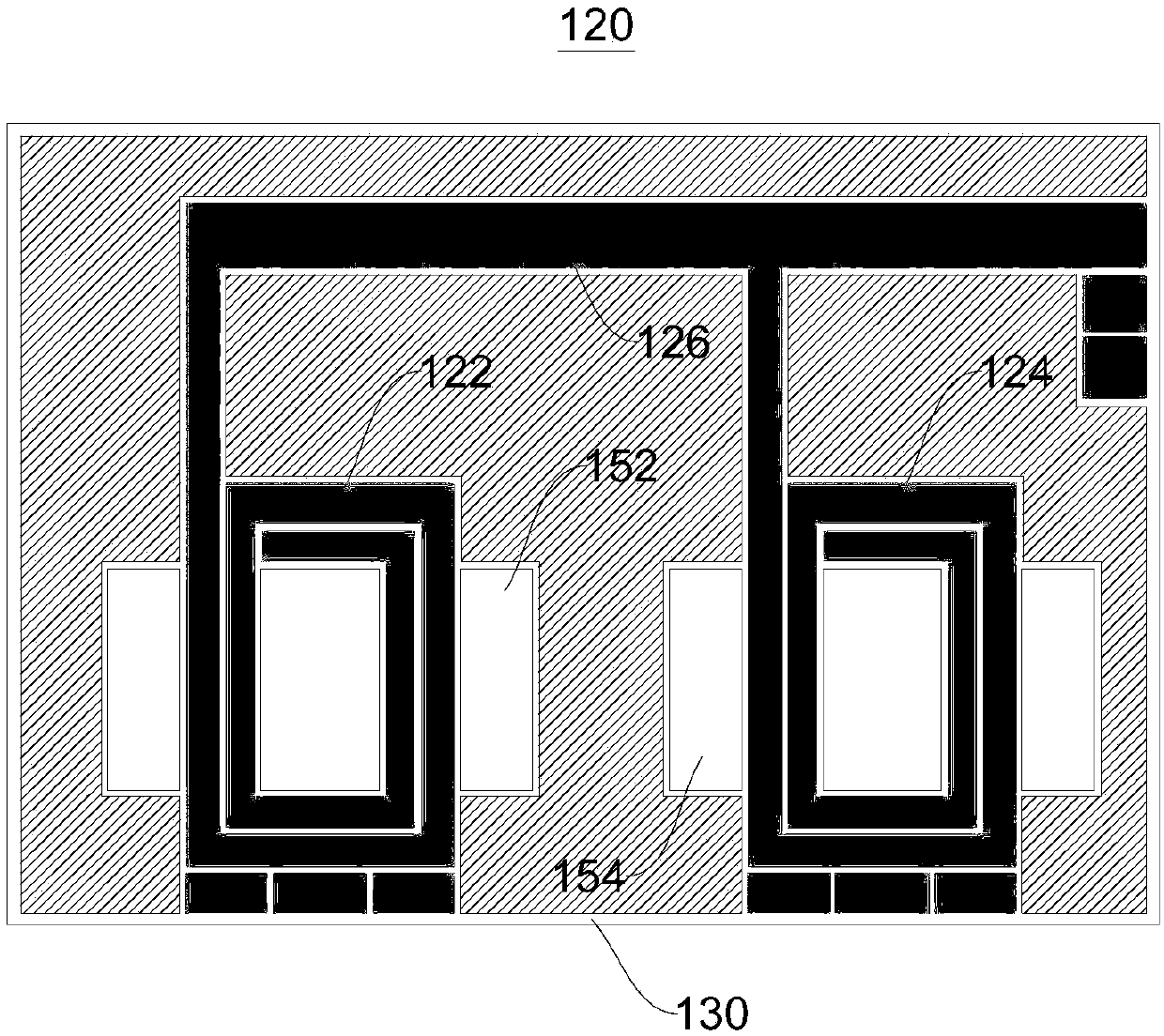

[0048] Step S1: Etching on the primary copper layer 120 produces a first primary winding 122, a second primary winding 124 and a common copper wire 126, the first primary winding 122 and the second primary winding 124 are connected to the common copper wire 126 electrical connections.

[0049] Step S2 : Etching the secondary copper layer 140 to produce the first secondary winding 142 and the second secondary winding 144 .

[0050] In steps S1 and S2, the windings of the first sub-transformer and the second sub-transformer are produced by etching on the copper layer. Compared with the method of winding the copper wire on the magnetic core of the wire-wound transformer, the uncertainty factor is small and consistent. Good performance, convenient for rapid mass production.

[0051] Step S3: stack ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com