Full-speed range control method of built-in permanent magnet synchronous motor based on fuzzy controller

A permanent magnet synchronous motor and fuzzy controller technology, applied in the direction of controlling generators, controlling electromechanical brakes, controlling electromechanical transmissions, etc., can solve the problems of unable to meet online adjustment parameters, high stability and weak, and difficult to obtain satisfactory control effects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The fuzzy controller-based full-speed range control method of the built-in permanent magnet synchronous motor of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

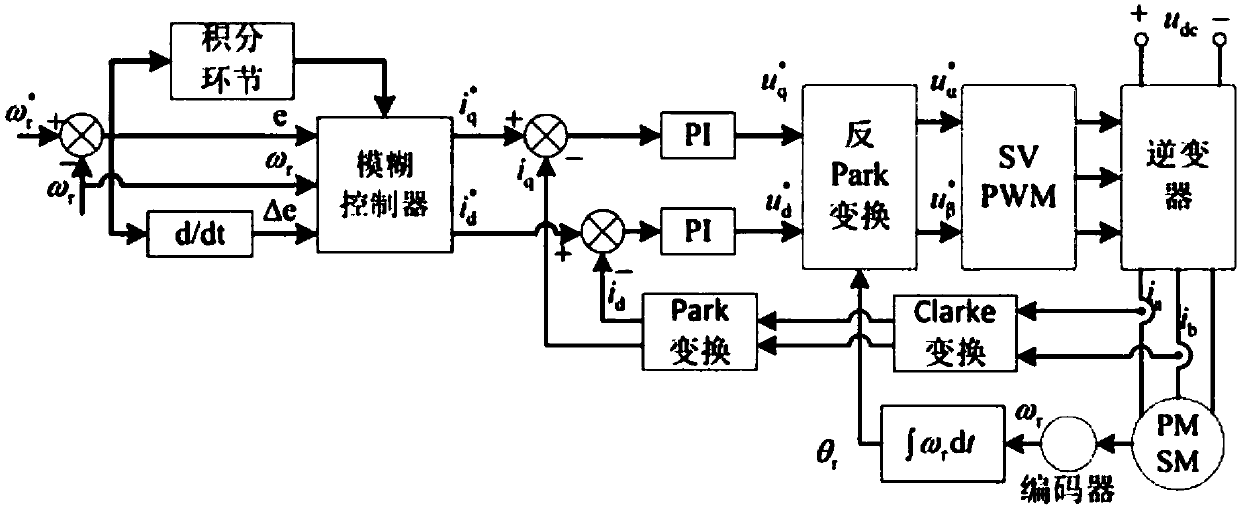

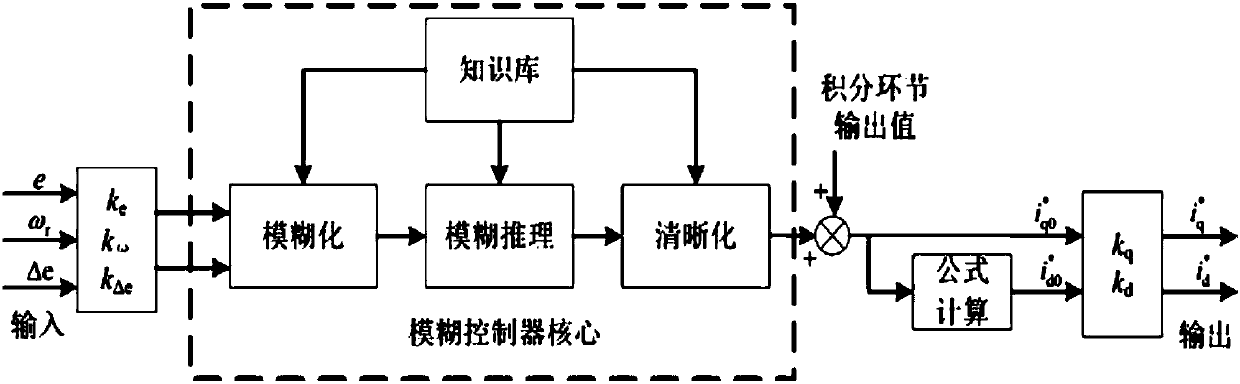

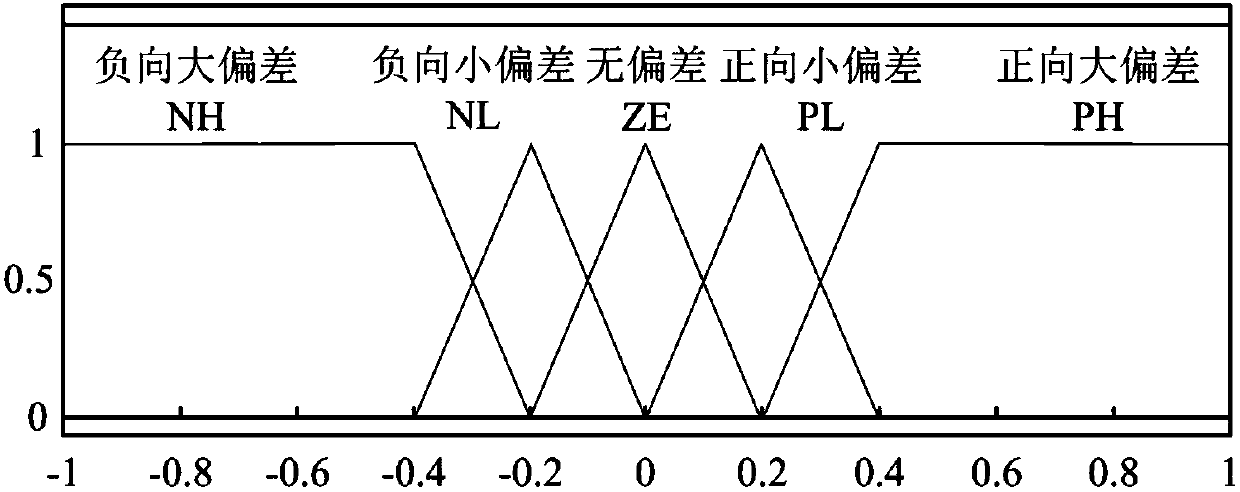

[0082] Such as figure 1 As shown, the fuzzy controller-based built-in permanent magnet synchronous motor full-speed domain control method of the present invention includes the following steps:

[0083] 1) Collect the three-phase stator current i of the built-in permanent magnet synchronous motor a i b i c , and carry out coordinate transformation to obtain the stator current direct axis component i d and stator current quadrature axis component i q ; The pulse signal is collected by the encoder installed on the motor, and the pulse signal is converted into the rotor position angle θ and the mechanical speed ω of the motor r ;

[0084] Collect the three-phase stator current i of the built-in permanent magnet synchronous motor through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com