Ruthenium catalyst for anthraquinone hydrogenation to prepare hydrogen peroxide, and preparation method thereof

A ruthenium catalyst and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of poor practicability and achieve good stability and high yield Less, reduce the effect of anthraquinone consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dissolving 0.4g ruthenium trichloride (Ru content 37.7%) in 100ml 1,3-propanediol and stirring to obtain a ruthenium trichloride mixed solution;

[0042] (2) Add 15g of 3.0mm spherical activated alumina carrier formed by rolling balls into the mixed solution obtained in step (1), and further stir for 0.5h;

[0043] (3) Stir and heat the mixed solution obtained in (2) to 180°C, and keep it for 0.5h, filter to obtain the catalyst, then wash off chloride ions with deionized water, and obtain 1% Ru / Al after vacuum drying 2 o 3 Catalyst, and keep it sealed.

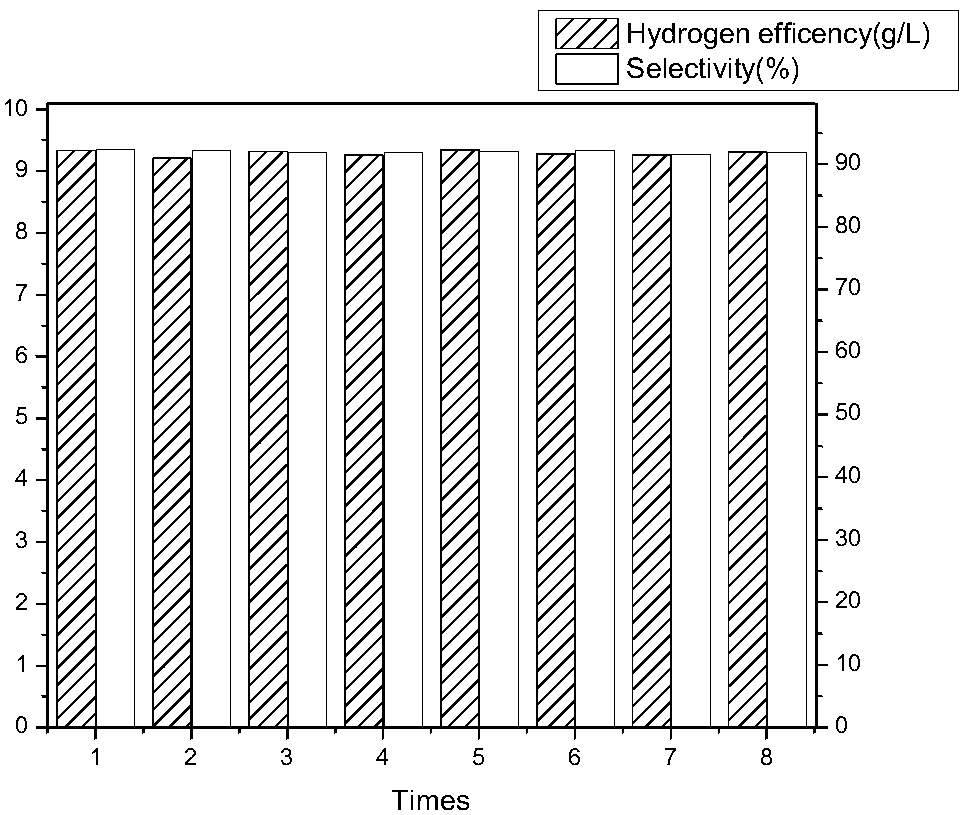

[0044] Add 3g of the above catalyst and 50mL of working solution into a 100mL autoclave, and react at 55°C and 0.3MPa for 1h. The hydrogenation efficiency of the reaction is 8.5g / L, and the selectivity is 95.2%.

Embodiment 2

[0046] (1) 0.2g ruthenium trichloride (Ru content 37.7%) is dissolved in 100ml ethylene glycol and stirred to obtain a ruthenium trichloride mixed solution;

[0047] (2) 15g extruded 3.0mm toothed spherical SiO 2 -Al 2 o 3 The carrier is added to the mixed solution obtained in step (1), and further stirred for 0.5h;

[0048] (3) Stir and heat the mixed solution obtained in (2) to 180°C, and keep it for 0.5h, filter to obtain the catalyst, then wash off the chloride ions with deionized water, and obtain 0.5% Ru / Al after vacuum drying 2 o 3 Catalyst, and keep it sealed.

[0049] Add 3 g of the above catalyst and 50 mL of working solution into a 100 mL autoclave, and react at 55° C. and 0.3 MPa for 1 hour. The hydrogenation efficiency of the reaction is 7.7 g / L, and the selectivity is 97.2%.

Embodiment 3

[0051] (1) 0.5g ruthenium nitrate (Ru content 30%) is dissolved in 100ml glycerol and stirred to obtain ruthenium nitrate mixed solution;

[0052] (2) Add 15 g of extruded 3.0 mm spherical activated alumina carrier into the mixed solution obtained in step (1), and further stir for 0.5 h;

[0053] (3) Stir and heat the mixed solution obtained in (2) to 180°C, and keep it for 0.5h, filter to obtain the catalyst, then wash off chloride ions with deionized water, and obtain 1% Ru / Al after vacuum drying 2 o 3 Catalyst, and keep it sealed.

[0054] Add 3 g of the above catalyst and 50 mL of working solution into a 100 mL autoclave, and react at 55° C. and 0.6 MPa for 1 hour. The hydrogenation efficiency of the reaction is 9.6 g / L, and the selectivity is 93.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com