Method for removing silicon in negative hardness wastewater

A hardness and waste water technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of difficult removal of effluent silicon compounds, failure to achieve expected results, low lime utilization rate, etc., to increase Silicon removal rate, wide range, and the effect of reducing the amount of sludge discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

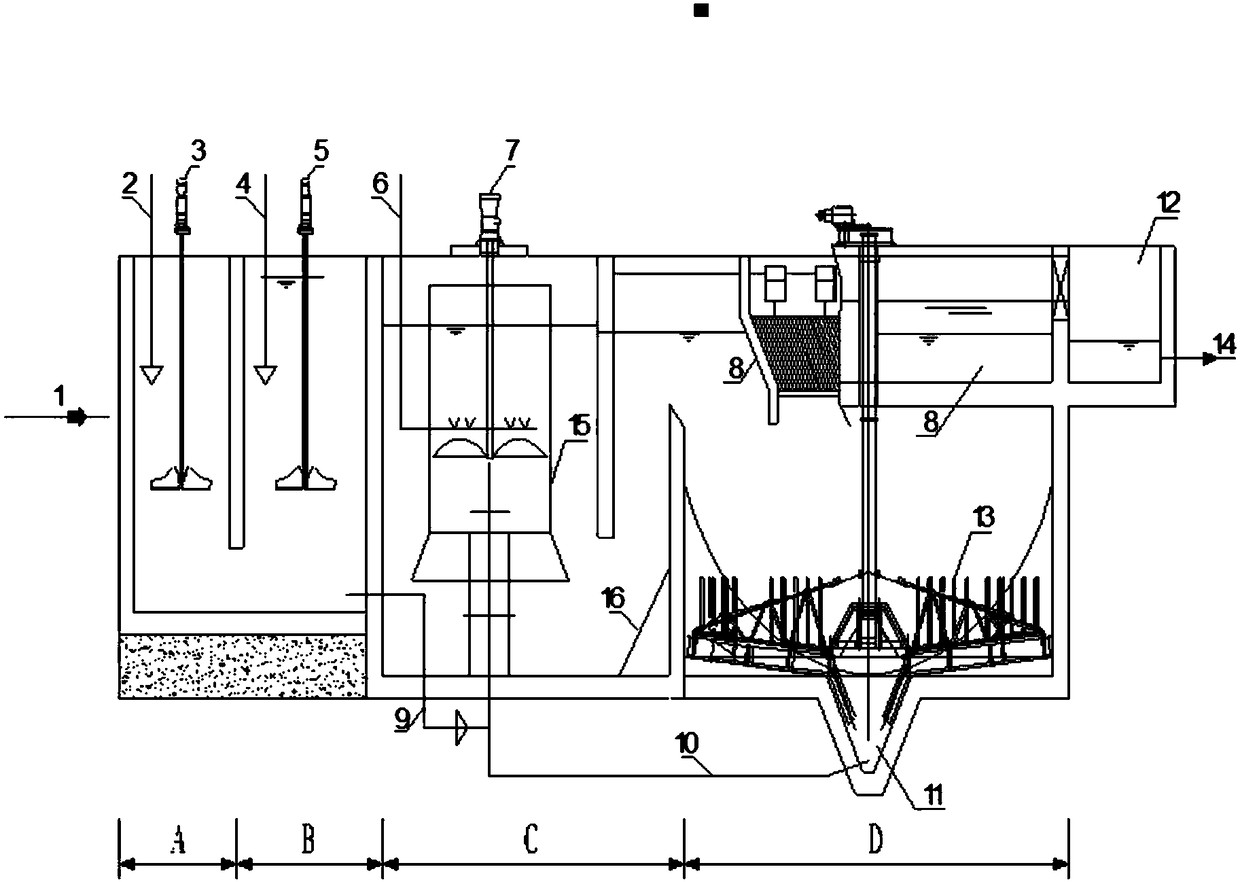

[0020] The water quality of an oilfield waste water contains 1740mg / L of silicon (as SiO 2 After lime and calcium chloride dosing area A, the amount of lime added is 2.1g / L, calcium chloride is 3.1g / L, rapid stirring and reaction in area A for 20min, and PAC is added in coagulation area B 100mg / L, the fast stirring time is 3min in the B area; 1.0mg / L PAM is added in the flocculation area C, and the slow stirring time is 12min in the D area; in the precipitation-concentration area D, the mud and water are separated rapidly, and the clear water is upward The sludge is separated into the sump through the inclined pipe, and the sludge sinks downward. The sludge is concentrated by the thickening sludge scraper and then discharged, and 4% of the sludge is returned to the flocculation zone C; the final effluent quality contains 11.9mg / L of silicon, The silicon removal rate reaches 99.3%.

Embodiment 2

[0022] The water quality of a gasification sewage water contains 98mg / L of silicon (as SiO 2 After lime and calcium chloride dosing area A, add lime at 0.26g / L and calcium chloride at 0.5g / L, stir and react in area A for 18min; add PAC at coagulation area B at 100mg / L, the fast stirring time in B area is 3min; the flocculation area C dosing PAM is 0.5mg / L, and the slow stirring time in D area is 12min; in the precipitation-concentration area D, the mud and water are separated rapidly, and the clear water flows upward , separated into the sump through the inclined tube, the sludge sinks, the sludge is concentrated by the thickening sludge scraper and then discharged, and 6% of the sludge is returned to the flocculation zone C; the final effluent quality contains 12.5mg / L of silicon, except The silicon rate reaches 87.2%.

Embodiment 3

[0024] The water quality of a water plant's reclaimed water contains 200mg / L of silicon (as SiO 2 After lime and calcium chloride dosing area A, add lime at 1.2g / L and calcium chloride at 2.1g / L, stir and react in area A for 20min; add PAC at coagulation area B at 100mg / L L, fast stirring time in B area is 3min; flocculation area C dosing PAM is 1.0mg / L, slow stirring time in D area is 12min; in precipitation-concentration area D, mud and water are separated rapidly, clear water flows upwards, The sludge is separated into the sump through the inclined tube, the sludge sinks, the sludge is concentrated by the thickening sludge scraper and then discharged, and 6% of the sludge is returned to the flocculation zone C; the final effluent quality contains 13.9mg / L of silicon, and the silicon is removed The rate reached 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com