New epoxy resin curing agent and preparation method thereof

An epoxy resin curing and epoxy resin technology, applied in the field of new epoxy resin curing agent and its preparation, can solve the problems of poor compatibility, easy deposition of flame retardants, affecting flame retardant effect, etc., so as to reduce curing The effect of stable temperature, flame retardant performance and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

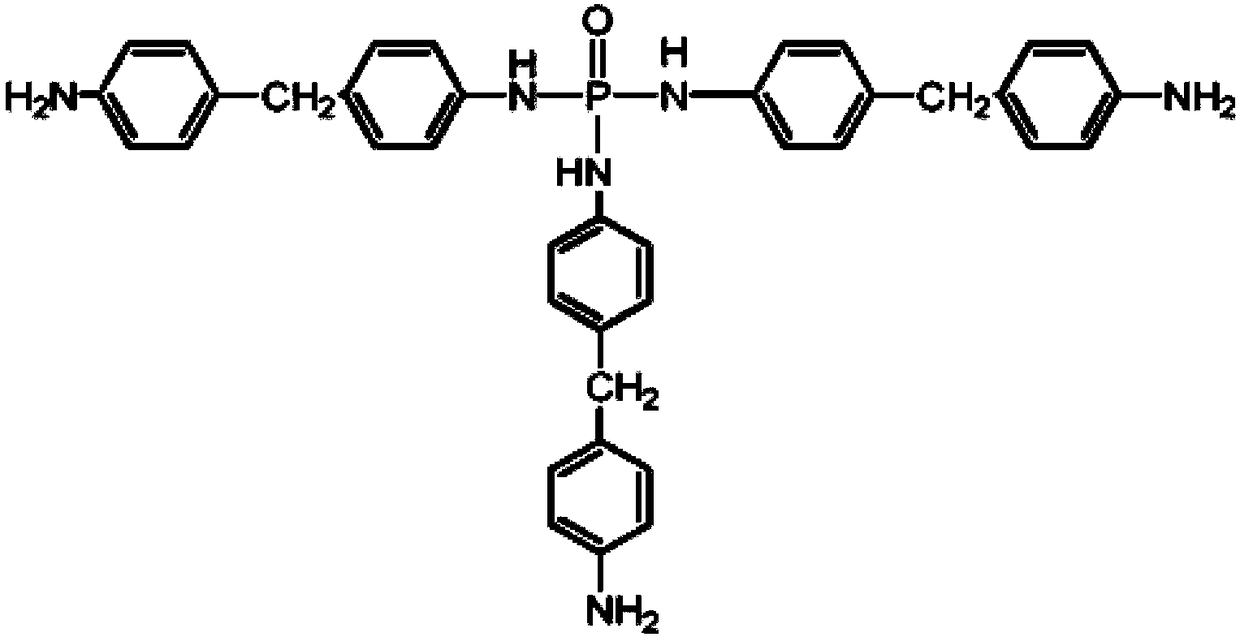

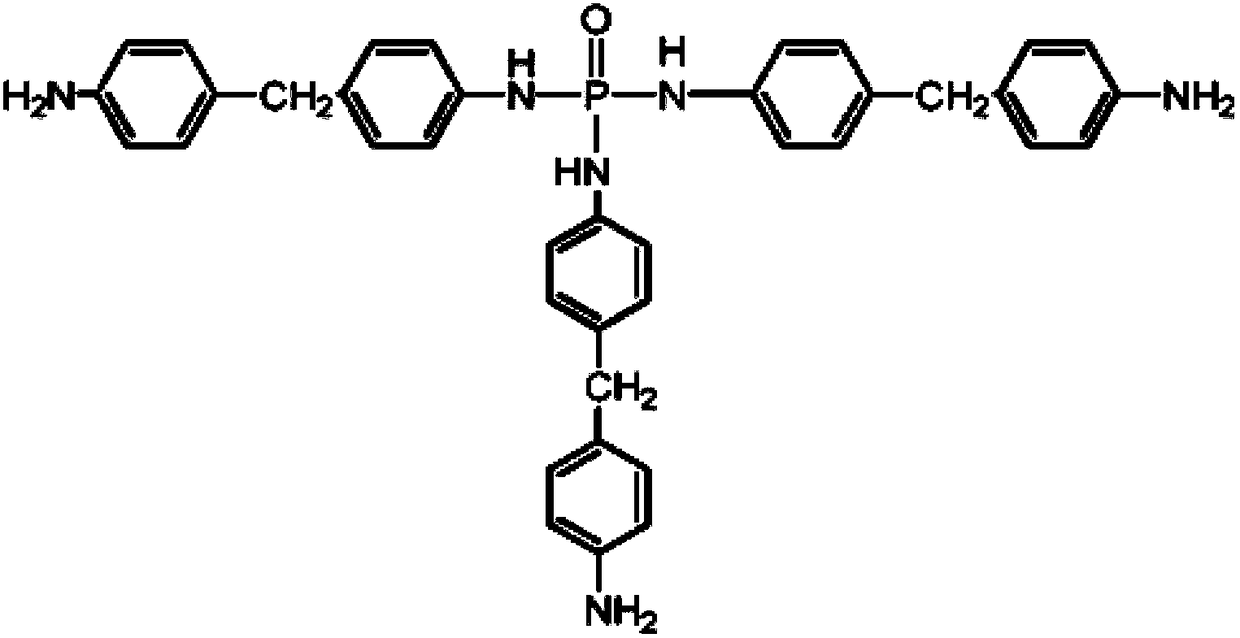

Image

Examples

Embodiment 1

[0019] Embodiment 1 of the present invention provides a kind of novel epoxy resin curing agent and preparation method thereof, and its method is as follows:

[0020] 1) Preparation of modified epoxy resin: dissolve 10g isophorone diamine and 2.6g phenylphosphorus dichloride in 20g dimethylformamide (analytical pure), add 0.01g methanol (analytical pure) as Catalyst, heat up to 120 ° C and stir for 1 hour. After the reaction, the product obtained is washed several times with a mixed solution of ethyl acetate and petroleum ether, filtered and dried to obtain the product, and then the product is added to 100g YDF-170 epoxy resin Warming up to 140°C for 1.5 hours to obtain a modified epoxy resin;

[0021] 2) Preparation of novel epoxy resin curing agent: under the condition of 130°C, 26g of phenylphosphorous dichloride was added to the reactor, and then 8g of diethyl phosphite was added, stirred and reacted for 4 hours to obtain the novel epoxy resin Oxygen resin curing agent;

...

Embodiment 2

[0025] Embodiment 2 of the present invention provides a kind of novel epoxy resin curing agent and preparation method thereof, and its method is as follows:

[0026] 1) Preparation of modified epoxy resin: 20g isophorone diamine, 5.5g phenylphosphorus dichloride are dissolved in 40g dimethylformamide, add 0.01g methanol (analytical pure) as catalyst, heat up to Stir and react at 110°C for 1.5 hours. After the reaction, wash the product obtained several times with a mixed solution of ethyl acetate and petroleum ether, filter and dry to obtain the product, and then add the product to 100g of YDF-170 epoxy resin and heat up to 160°C Reaction 2 hours obtains modified epoxy resin;

[0027] 2) Preparation of novel epoxy resin curing agent: under the condition of 105°C, 26g of phenylphosphorous dichloride was added to the reactor, then 8g of diethyl phosphite was added, stirred and reacted for 3 hours to obtain the novel epoxy resin Oxygen resin curing agent;

[0028] 3) Add 36.1 g...

Embodiment 3

[0031] Embodiment 3 of the present invention provides a kind of novel epoxy resin curing agent and preparation method thereof, and its method is as follows:

[0032] 1) Preparation of modified epoxy resin: 30g isophorone diamine, 7.9g phenylphosphorus dichloride are dissolved in 50g dimethylformamide, add 0.01g triethanolamine (analytical pure) as catalyst, heat up Stir the reaction at 115°C for 2 hours. After the reaction, the product obtained is washed several times with a mixed solution of ethyl acetate and petroleum ether, filtered and dried to obtain the product, and then the product is added to 100g of YDF-170 epoxy resin and heated to 150 ℃ reaction for 2 hours to obtain modified epoxy resin;

[0033] 2) Preparation of novel epoxy resin curing agent: under the condition of 120°C, 26g of phenylphosphorous dichloride was added to the reactor, then 8g of diethyl phosphite was added, stirred and reacted for 3.5 hours to obtain the novel epoxy resin Oxygen resin curing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com