Method of preparing polysaccharide emulsion gel from Pickering emulsion

A technology of emulsion gel and emulsion, which is applied in the fields of application, edible oil/fat, food science, etc., can solve the problems that Kedelan has no surface activity and cannot form stable emulsion, and achieves the effect of high emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 2g of wood pulp board into a three-necked flask, add 6mL of deionized water, add 100mL of 85% phosphoric acid, stir at 0°C for 24h, add the cellulose solution to 500mL of deionized water to form flocculent cellulose, and centrifuge until The pH is constant, and a regenerated cellulose suspension with a mass fraction of 0.5-5% is obtained.

[0027] (2) Take 5 g of the regenerated cellulose suspension of step (1) with a mass fraction of 0.5%, add 5 g of sunflower oil, and homogeneously disperse for 3 minutes at a speed of 10,000 rpm in a homogenizer to obtain stable sunflower oil / fiber Vegan Pickering Lotion.

[0028] (3) Add 2wt% curdran to the Pickering emulsion obtained in step (2), stir to obtain a stable polysaccharide emulsion.

[0029] (4) Take 5 g of curdlan suspension with a mass fraction of 2%, add 5 g of sunflower oil, and homogeneously disperse in a homogenizer at a speed of 10,000 rpm for 3 minutes to obtain a sunflower oil / curdan mixture.

[0030] ...

Embodiment 2

[0033] (1) Add 2g of wood pulp board into a three-necked flask, add 6mL of deionized water, add 100mL of 85% phosphoric acid, stir at 0°C for 24h, add the cellulose solution to 500mL of deionized water to form flocculent cellulose, and centrifuge until The pH is constant, and a regenerated cellulose suspension with a mass fraction of 0.5-5% is obtained.

[0034] (2) Take 5 g of the regenerated cellulose suspension of step (1) with a mass fraction of 0.5%, add 5 g of sunflower oil, and homogeneously disperse for 3 minutes at a speed of 10,000 rpm in a homogenizer to obtain stable sunflower oil / fiber Vegan Pickering Lotion.

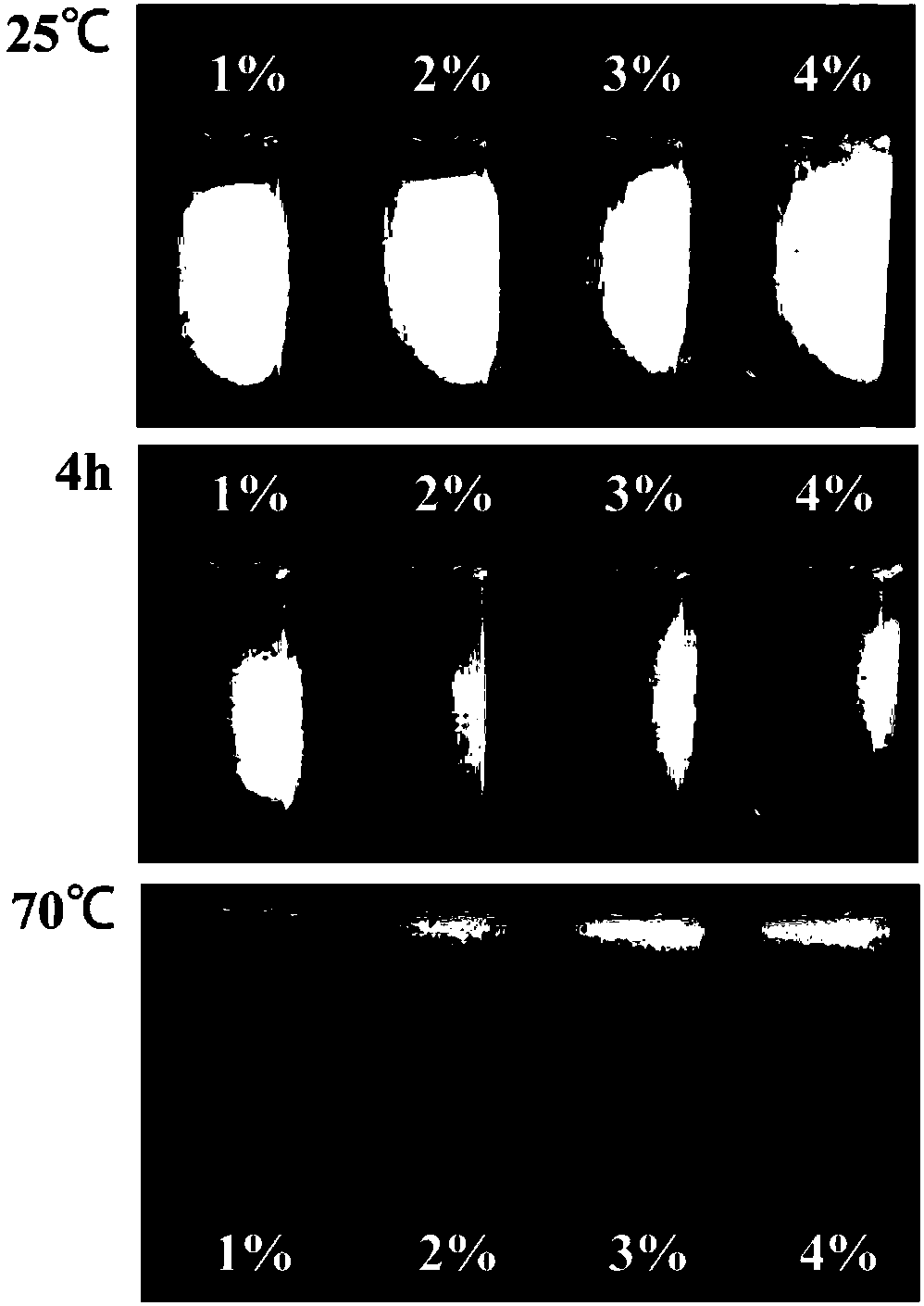

[0035] (3) Add 1wt%, 2wt%, 3wt%, 4wt% of curdlan to the Pickering emulsion obtained in step (2), stir, heat at 70°C, keep warm for 1h, and then cool at 10°C to obtain polysaccharide emulsion gel .

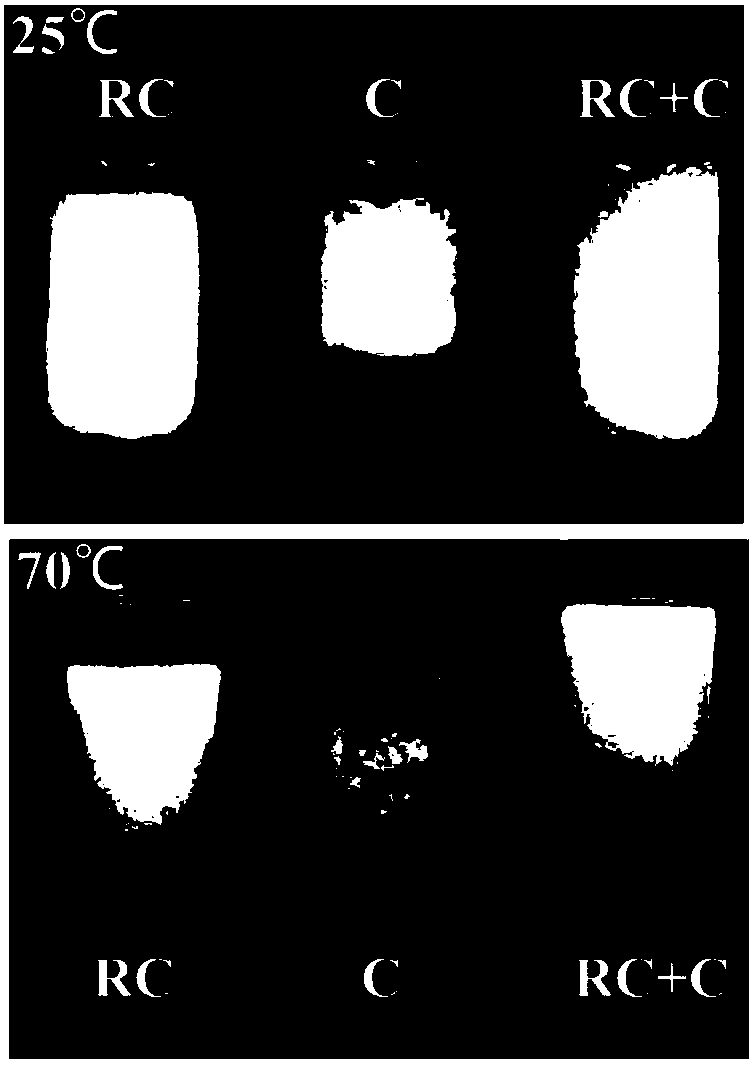

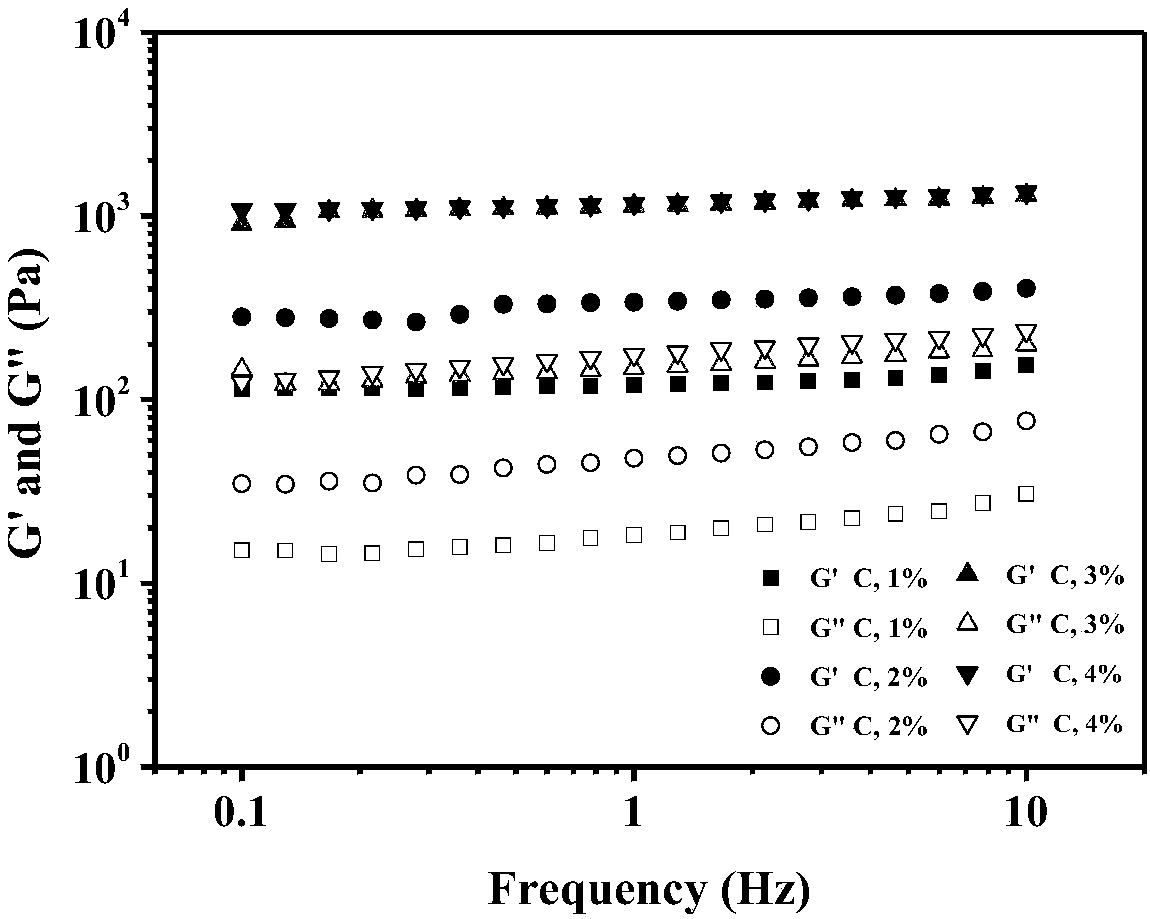

[0036] In order to study the stability of the emulsion and emulsion gel prepared in this example, the samples with different available content were left stand...

Embodiment 3

[0039] (1) Add 2g of wood pulp board into a three-necked flask, add 6mL of deionized water, add 100mL of 85% phosphoric acid, stir at 0°C for 24h, add the cellulose solution to 500mL of deionized water to form flocculent cellulose, and centrifuge until The pH is constant, and a regenerated cellulose suspension with a mass fraction of 0.5-5% is obtained.

[0040] (2) Take 5 g of the regenerated cellulose suspension of step (1) whose mass fraction is 0.3%, 0.5%, and 1%, respectively, add 5 g of sunflower oil, and homogeneously disperse for 3 min at a speed of 10,000 rpm in a homogenizer to obtain Stabilized Sunflower Oil / Cellulose Pickering Emulsion.

[0041] (3) Add 2wt% curdlan to the three Pickering emulsions obtained in step (2), stir, heat at 70°C, keep warm for 1h, and then cool at 10°C to obtain polysaccharide emulsion gel.

[0042] In order to study the stability of the emulsion and emulsion gel prepared in this example, the Pickering emulsion samples with different reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com