Nutritional bean dregs, production method thereof and dietary bean dregs

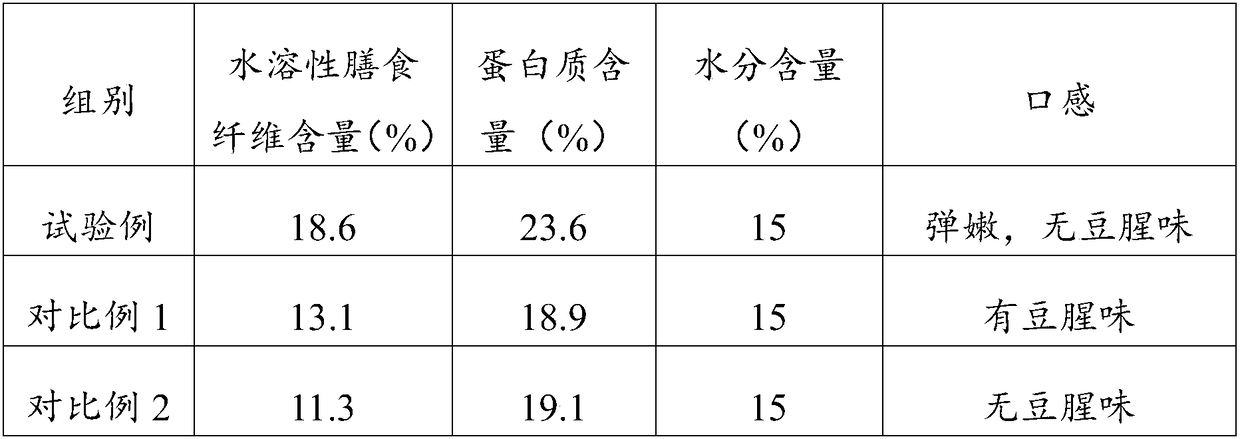

A technology of bean dregs and nutrition, which is applied in the direction of food science, food ingredients as taste improvers, etc., can solve the problems of uneven quality of bean dregs, low nutritional content, poor taste, etc., and achieve tender taste, easier absorption, and increased content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Nutritional okara, the protein content in the okara is 20wt%, the water-soluble dietary fiber content in the okara is 10wt%, and the particle size of the nutritious okara is 0.01mm.

[0039] The preparation method of above-mentioned nutritious bean dregs comprises the following steps:

[0040] (1) Soak soybeans;

[0041] (2) beating and crossing a 140-mesh sieve to obtain soybean milk;

[0042] (3) Cooking: The soybean milk obtained in step (2) is continuously boiled in a sealed device, first at 55°C, then at 75°C, and finally at 95°C to obtain cooked slurry;

[0043] (4) slurry separation: the cooked slurry obtained in step (3) is separated to obtain slag;

[0044] (5) Extruding: extruding the slag obtained in step (4) at 100° C. for 5 minutes to obtain the nutritious okara, the water content of which is 20%.

Embodiment 2

[0046] Nutritional okara, the protein content in the okara is 21.3wt%, the water-soluble dietary fiber content in the okara is 12.2wt%, and the particle size of the nutritious okara is 0.009mm.

[0047] The preparation method of above-mentioned nutritious bean dregs comprises the following steps:

[0048] (1) Soak soybeans;

[0049] (2) beat an oar, cross 170 mesh sieves, obtain soya-bean milk;

[0050] (3) Cooking: the soybean milk obtained in step (2) is continuously boiled in a sealed device, first at 65°C for 3 minutes, then at 85°C for 3 minutes, and finally at 105°C for 3 minutes, Obtain cooked slurry;

[0051] (4) slurry separation: the cooked slurry obtained in step (3) is separated to obtain slag;

[0052] (5) Extruding: extruding the slag obtained in step (4) at 140° C. for 3 minutes to obtain the nutritious okara, the water content of which is 18%.

Embodiment 3

[0054] Nutritional okara, the protein content in the okara is 20.6wt%, the water-soluble dietary fiber content in the okara is 13.6wt%, and the particle size of the nutritious okara is 0.0075mm.

[0055] The preparation method of above-mentioned nutritious bean dregs comprises the following steps:

[0056] (1) Soak soybeans: add water to the soybeans, do not cross the soybeans, the hardness of the water is less than 2 degrees, the chromaticity<5 degrees, and the conductivity<20ns / cm, add sodium carbonate to the water, and adjust the pH of the solution to 8. Soak at 35°C for 5 hours;

[0057](2) beating and passing through a 200-mesh sieve to obtain soybean milk;

[0058] (3) Cooking: the soybean milk obtained in step (2) is continuously boiled in a sealed device, first at 55°C for 5 minutes, then at 75°C for 5 minutes, and finally at 95°C for 5 minutes, Obtain cooked slurry;

[0059] (4) slurry separation: utilize centrifugation to separate the cooked slurry obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com