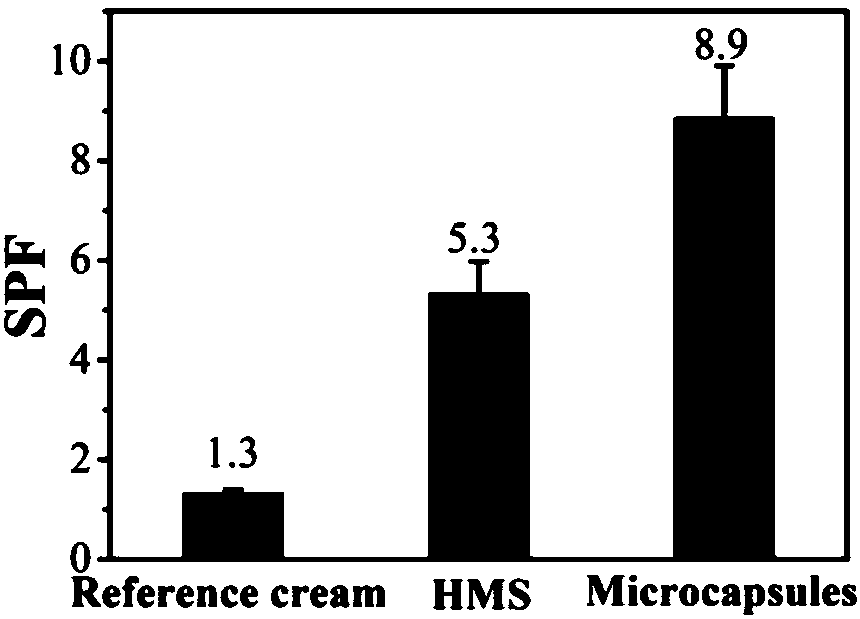

Sun protection microcapsule taking poly(ethylene glycol) diacrylate as wall material and preparation method thereof

A technology of polyethylene glycol diacrylate and microcapsules, which is applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of microcapsules that have not been reported before, and achieve the improvement of UV protection effect with a simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of oil phase: Add 10 g of homosalate (HMS) into a 100 ml beaker, add 0.1 g of dibenzoyl peroxide (BPO) and stir evenly under heating at 50° C. to obtain an oil phase.

[0032] (2) Preparation of water phase: 10g polyvinyl alcohol (degree of hydrolysis is 88%) powder is joined in the beaker, then add 90g deionized water, stir 2h in 80 ℃ of water baths, make polyvinyl alcohol (degree of hydrolysis is 88%) 88%) was completely dissolved, and made into 10% polyvinyl alcohol aqueous solution as emulsifier solution for subsequent use. 10 g of the above-mentioned 10% polyvinyl alcohol aqueous solution, 2 g of polyethylene glycol diacrylate (molecular weight: 200) and 27.9 g of deionized water were respectively added into a 100 ml beaker, and the water phase was obtained after stirring evenly.

[0033] (3) Preparation of sunscreen microcapsules: Add the water phase (39.9g) in step (2) to the oil phase (10.1g) in step (1), mix the two phases and homogenize for 3mi...

Embodiment 2

[0037] (1) Preparation of the oil phase: 15 g of octyl salicylate was added to a 100 ml beaker, and then 0.1 g of dibenzoyl peroxide (BPO) was added and stirred evenly under heating at 50° C. to obtain the oil phase.

[0038] (2) Preparation of the water phase: Add 10g of polyvinyl alcohol (the degree of hydrolysis is 88%) into a beaker, then add 90g of deionized water, and stir in a water bath at 80°C for 2 hours to completely dissolve the polyvinyl alcohol to obtain 10% polyvinyl alcohol aqueous solution is the emulsifier solution for later use. 7.5 g of the above-mentioned 10% polyvinyl alcohol aqueous solution, 2 g of polyethylene glycol diacrylate (molecular weight: 200) and 25.4 g of deionized water were respectively added into a 100 ml beaker, and the water phase was obtained after stirring evenly.

[0039] (3) Preparation of sunscreen microcapsules: Add the water phase (34.9g) in step (2) to the oil phase (15.1g) in step (1), mix the two phases and homogenize for 3min ...

Embodiment 3

[0042] (1) Preparation of the oil phase: Add 10 g of octocrylene and 5 g of octyl salicylate into a 100 ml beaker, then add 0.1 g of dibenzoyl peroxide (BPO) and stir evenly under heating at 50 ° C to obtain oil Mutually.

[0043] (2) Preparation of the water phase: Add 10g of polyvinyl alcohol (the degree of hydrolysis is 88%) into a beaker, then add 90g of deionized water, and stir in a water bath at 80°C for 2 hours to completely dissolve the polyvinyl alcohol to obtain 10% polyvinyl alcohol aqueous solution is the emulsifier solution for later use. 7.5 g of the above-mentioned 10% polyvinyl alcohol aqueous solution, 2 g of polyethylene glycol diacrylate (molecular weight: 400) and 25.4 g of deionized water were respectively added into a 100 ml beaker, and the water phase was obtained after stirring evenly.

[0044](3) Preparation of sunscreen microcapsules: Add the water phase (34.9g) in step (2) to the oil phase (15.1g) in step (1), mix the two phases and homogenize for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com