High-strength dust-proof quicklime desiccant packaging film and production method thereof

A production method and technology of quicklime, applied in packaging, wrapping paper, packaged food, etc., can solve problems such as poor water permeability, poor drying effect, and low tear strength, and achieve good gas passage performance and ensure no lint , Improve the effect of heat sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

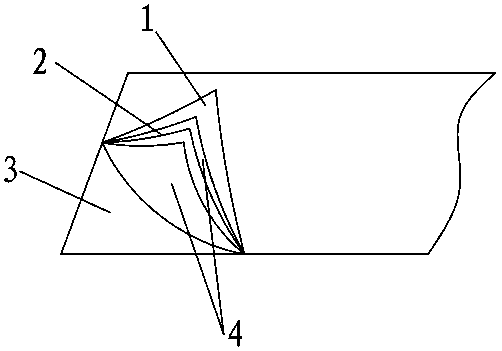

[0037] Example 1: Structure of high-strength dust-proof quicklime desiccant packaging film

[0038] like figure 1 As shown, the high-strength dust-proof quicklime desiccant packaging film includes PET spunbond non-woven fabric 1, milky white PE breathable film 2 and perforated breathable PE film 3, PET spunbond non-woven fabric 1, milky white PE breathable film 2 and perforated The breathable PE films 3 are compounded by AD adhesive 4 (polyurethane two-component adhesive). Among them, the weight of PET spunbonded non-woven fabric 1 is 40-80g / m 2 ; Milky white PE breathable film weighs 20-40g / m2 in 2 grams 2 ; The diameter of the air holes in the perforated air-permeable PE film 3 is 0.5-3 mm, and the distance between the air holes is 1-5 mm.

Embodiment 2

[0039] Embodiment 2: the production method of high-strength dust-proof quicklime desiccant packaging film

[0040] 1) Take the PET spunbonded nonwoven fabric and use flexo plate water-based ink to print text and patterns on the surface to obtain PET spunbonded nonwoven fabric 1;

[0041] 2) Weigh the raw materials according to the following weight ratio: LDPE 15%, LLDPE 20%, MLLDPE 20%, elastomer PE 5% and calcium carbonate 40%, and produce milky white PE breathable film through casting process;

[0042] 3) Weigh each raw material according to the following weight ratio: 20% LDPE, 40% LLDPE and 40% MLLDPE, obtain a breathable PE film through the film making process, and carry out thermal perforation treatment on the PE film. The thermal perforation condition is: the needle roller adopts Electronic heating tube internal heating method, punching temperature 100°C, needle roller diameter 150mm, needle diameter 0.5mm, needle length 5mm, to obtain perforated breathable PE film 3; ...

Embodiment 3

[0052] Embodiment 3: the production method of high-strength dust-proof quicklime desiccant packaging film

[0053] 1) Take the PET spunbonded nonwoven fabric and use flexo plate water-based ink to print text and patterns on the surface to obtain PET spunbonded nonwoven fabric 1;

[0054] 2) Weigh each raw material according to the following weight ratio: LDPE 20%, LLDPE 15%, MLLDPE 10%, elastomer PE 10% and calcium carbonate 45%, and produce milky white PE breathable film through casting process;

[0055] 3) Weigh each raw material according to the following weight ratio: 30% LDPE, 30% LLDPE, 40% MLLDPE, obtain a breathable PE film through the film making process, and carry out thermal perforation treatment on the PE film. The thermal perforation condition is: the needle roller adopts Electronic heating tube internal heating method, punching temperature 120°C, needle roller diameter 200mm, needle diameter 1mm, needle length 3mm, to obtain perforated breathable PE film 3;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com