A kind of degradable antibacterial composite fresh-keeping film and preparation method thereof

A composite fresh-keeping and antibacterial technology, applied in the field of related materials, can solve the problems of non-degradable plastic wrap, harmful to human health, and natural environment hazards, to solve environmental problems and human health problems, good fresh-keeping effect, high air permeability barrier Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of PVA rubber: Weigh an appropriate amount of PVA17-88 and add it to a three-neck flask, add an appropriate amount of distilled water, place it in a constant temperature water bath, turn on a high-power stirrer to stir and slowly heat to 60-70 degrees Celsius, then weigh Put a certain amount of glycerin in a beaker, add an appropriate amount of water to heat it to dissolve, slowly add it into the above-mentioned three-necked flask under the stirring of the stirrer, mix well, and then add an appropriate amount of citric acid to remove it. Bubbles, and close the agitator, ultrasonic defoaming filtration treatment to obtain PVA composite glue.

[0029] Pour the prepared PVA composite glue into the mold (glass plate 30×40) by tape casting method, put it into the oven, the temperature of the oven is 55°C, and the baking time is 6 hours. During this period, use a level to ensure the level of the mold, and take it out after the time is up. The mold is placed at 25°...

experiment example

[0037] In this experiment, after determining the mass ratio of chitosan solution, β-cyclodextrin, and glycerol by setting up a single factor experiment, an orthogonal experimental design with 3 factors and 3 levels was adopted, and the L9(33) orthogonal table was used to arrange the experiment. The degree of influence of various factors on the fresh-keeping performance of the film was studied.

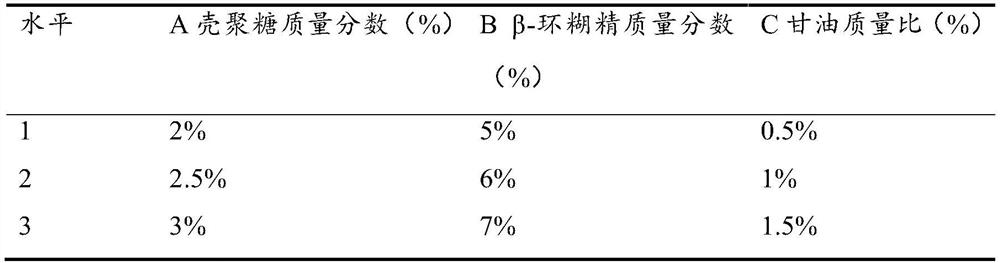

[0038] Table 1L 9 (3 3 ) Orthogonal experimental factor level table

[0039]

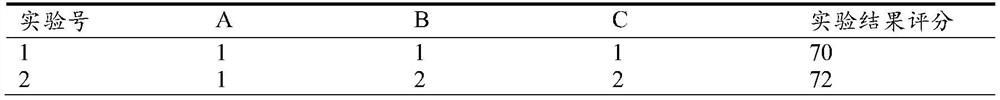

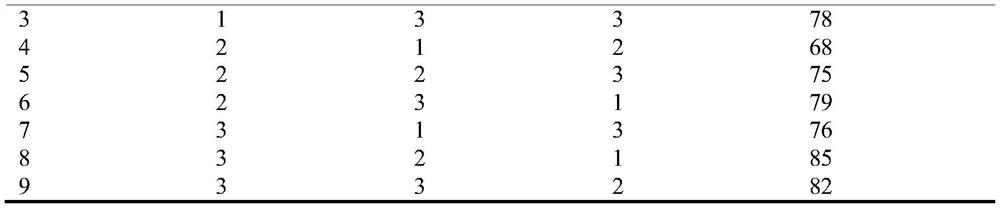

[0040] Table 2L 9 (3 3 ) Orthogonal experiment scheme and results

[0041]

[0042]

[0043] It can be seen from Table 2 that the optimal proportions of the mass ratio of the polysaccharide solution, the mass ratio of β-cyclodextrin and the mass ratio of glycerin are: 3%, 7%, and 1%, respectively.

[0044] 3 By studying the physical and chemical properties of the film, determine the optimal ratio in the orthogonal

[0045] According to GBT 1040.3-2006 and texture analyzer, composite film tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com