Bio-fermentation method for preparing 1,3-propanediol

A technology of biological fermentation and propylene glycol, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of low concentration, high cost, low fermentation level, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

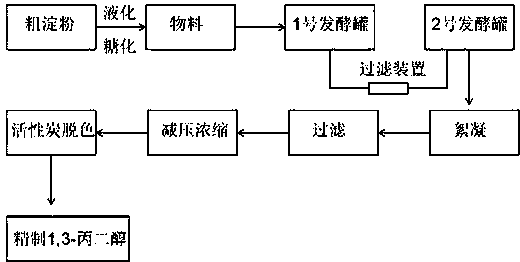

Method used

Image

Examples

Embodiment 1

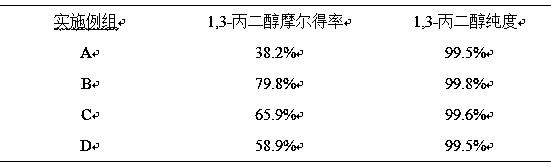

[0024] Set A, B, C, D implementation groups

[0025] 1. Liquefaction and saccharification of crude starch

[0026] Add 500g of starch, add water to make starch milk with a mass fraction of 36%, add 0.6 g of high temperature resistant α-amylase (5U / g) and the DE value of the liquefaction solution is 18%. The liquefied solution was introduced into the mash tun, and 5 g of glucoamylase (200 U / g) was added, and the glucose value measured at the end of saccharification was 98%.

[0027] 2. Fermentation of saccharification liquid to produce glycerin

[0028] Prepare the feed solution (g / L): urea 2.5, glucose concentration 315, corn steep liquor 3 with a phosphorus content of 80 μg / mL, astragalus extract 10 (groups A and C do not add astragalus extract, groups B and D add). Introduce the 50L culture medium after continuous elimination and the expanded strains into the No. 1 fermenter that has been strictly sterilized. Introduce sterile air for aerobic fermentation. The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com