System and method for focusing or separating submicron nano-particles on the basis of non-Newtonian effect

A non-Newtonian effect and nanoparticle technology, applied in chemical instruments and methods, laboratory containers, special data processing applications, etc., can solve the problems of manufacturing difficulty and rising production costs, so as to improve scalability and avoid irreversibility Non-destructive, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

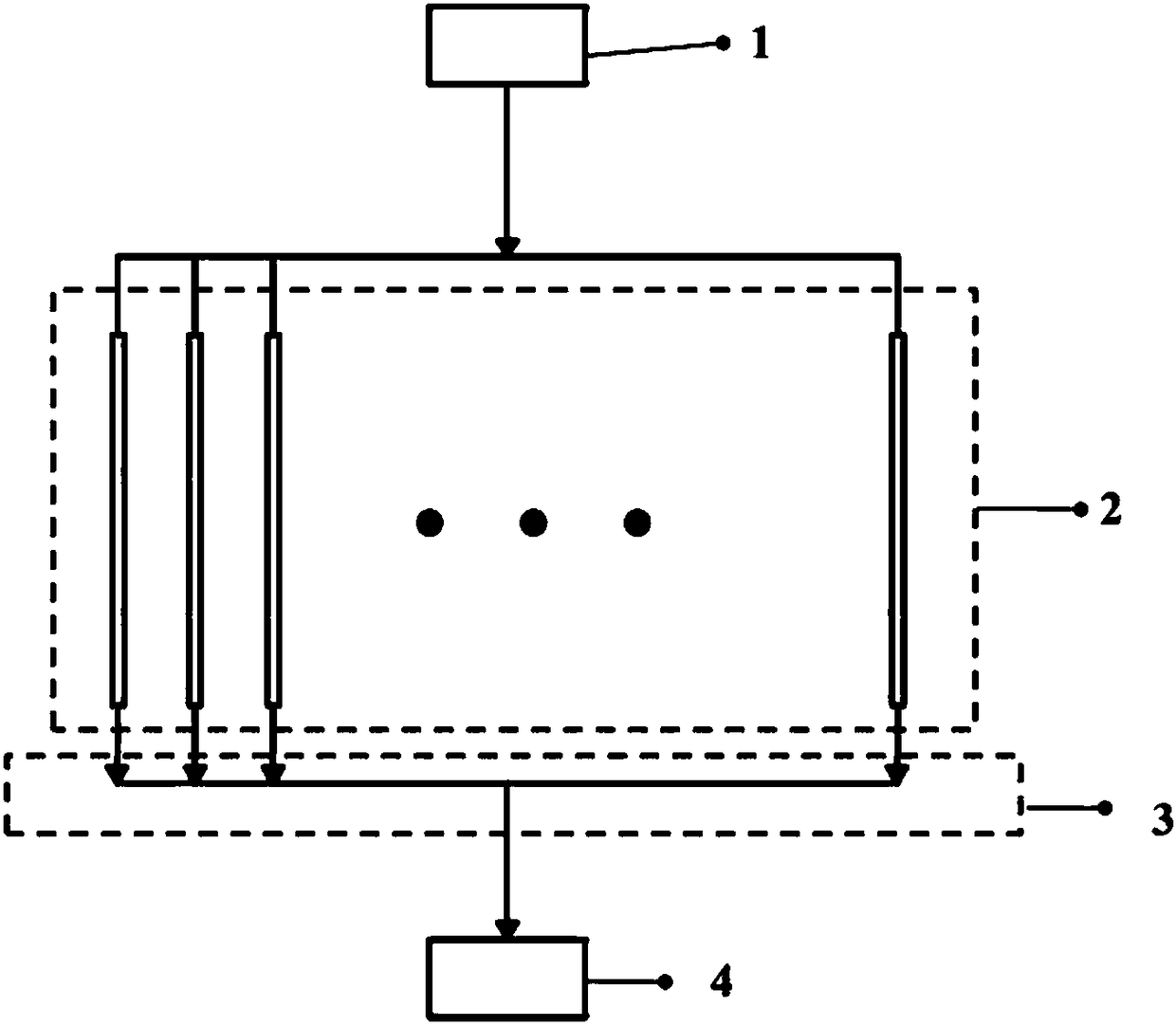

[0042] This example provides the attached figure 1 The shown system for focusing and separating submicron nanoparticles based on the non-Newtonian effect, the system includes:

[0043] Delivery device 1 for delivering working fluid with non-Newtonian fluid effect;

[0044] Microfluidic unit 2 containing microchannels (Liu, C.; Xue, C.; Chen, X.; Shan, L.; Tian, Y.; Hu, G. Size-Based Separation of Particles and Cells Utilizing Viscoelastic Effectsin Straight Microchannels.Anal.Chem.2015,87,6041-6048.), the microfluidic unit 2 communicates with the delivery device 1 through a pipeline, and is used for submicron nanoparticles in the working fluid delivered by the delivery device 1 Focusing in the microchannel;

[0045] A bifurcated outlet 3 arranged at the end of the microfluidic unit 2, the central branch of the bifurcated outlet 3 is used to focus submicron nanoparticles;

[0046] A collection device 4 for collecting target submicron nanoparticles connected to the branch o...

Embodiment 2

[0068] This example presents systems and methods for focusing DNA molecules.

[0069] This example provides the attached Image 6 The system shown for focusing submicron nanoparticles based on the non-Newtonian effect includes:

[0070] Delivery device 1 for delivering working fluid with non-Newtonian fluid effect;

[0071] A microfluidic unit 2 comprising a microchannel, the microfluidic unit 2 is connected to the delivery device 1 through a pipeline, and is used to separate the submicron nanoparticles in the working fluid delivered by the delivery device 1 in the microchannel;

[0072] A branch outlet 3 is provided at the end of the microfluidic unit 2, and the central branch of the branch outlet 3 is used to collect and focus submicron nanoparticles;

[0073] A collection device 4 for collecting target submicron nanoparticles is connected to the central branch of the bifurcation outlet 3 .

[0074] In the present invention, the delivery of the working fluid by the delive...

Embodiment 3

[0094] This example presents systems and methods for isolating submicron nanoparticles.

[0095] This example provides the attached Figure 9 The shown system for focusing and separating submicron nanoparticles based on the non-Newtonian effect, the system includes:

[0096] Delivery device 1 for delivering working fluid with non-Newtonian fluid effect;

[0097] A microfluidic unit 2 comprising a microchannel, the microfluidic unit 2 communicates with the delivery device 1 through a pipeline, and is used to separate the submicron nanoparticles in the working fluid delivered by the delivery device 1 in the microchannel; in order to improve Separation throughput, the microfluidic unit 2 uses a parallel structure;

[0098] The branch outlet 3 provided at the end of the microfluidic unit 2, the central branch 31 of the branch outlet 3 is used to separate submicron nanoparticles with a larger diameter, and the side branch 32 of the branch outlet 3 is used to separate particles wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com