Electronic device packaging tape

A technology of electronic devices and adhesive tapes, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve problems such as warping of electronic device packages, and achieve the effect of suppressing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

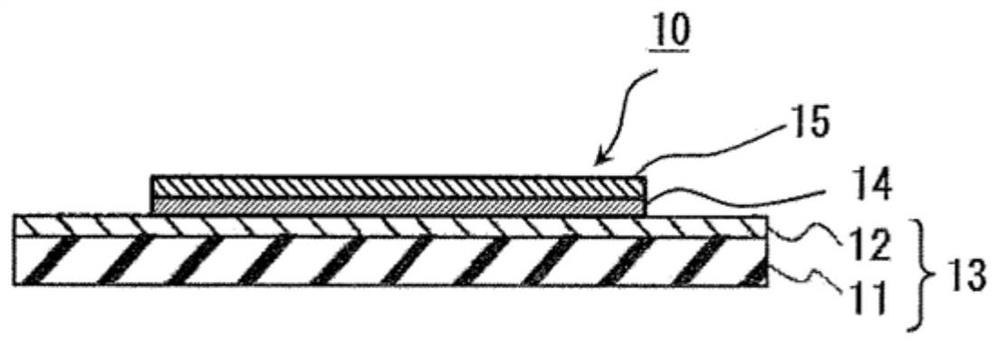

[0040]The preparation of the acrylic polymer can be carried out by applying an appropriate method such as a solution polymerization method, an emulsion polymerization method, a bulk polymerization method, and a suspension polymerization method to a mixture of one or more component monomers. From the viewpoint of preventing wafer contamination, the adhesive layer 12 preferably suppresses the composition containing low molecular weight substances. From this viewpoint, it is preferable to use an acrylic polymer having a weight average molecular weight of 300,000 or more, especially 400,000 to 3 million. As the main component, the adhesive can also be an appropriate crosslinking type based on an internal crosslinking method or an external crosslinking method.

[0041]In addition, in order to control the cross-linking density of the adhesive layer 12 and improve the pick-up properties, for example, the use of polyfunctional isocyanate-based compounds, polyfunctional epoxy-based compounds, m...

Embodiment 2~4、 comparative example 1~4

[0182]The electronic devices of Examples 2 to 4 and Comparative Examples 1 to 4 were produced by the same method as Example 1, except that the combination of the adhesive tape, adhesive layer composition, and metal layer was set to the combination described in Table 1. Tape for packaging.

[0183]The following measurements and evaluations were performed on the electronic device packaging tapes of Examples 1 to 4 and Comparative Examples 1 to 4. The results are shown in Table 1.

[0184](Storage modulus)

[0185]The storage elastic modulus at 25°C of the adhesive layer used in each example and each comparative example was measured as follows. Adhesion of the adhesive layer used in each example and comparative example on a polyethylene terephthalate (PET) separator with a thickness of 25μm so that the film thickness after drying will reach 30μm After the agent layer composition is dried, it is attached to a polyethylene terephthalate (PET) separator with a thickness of 25 μm, the adhesive laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com