Sodium fructose diphosphate capsule and preparation method thereof

A technology of sodium fructose diphosphate and capsules, applied in the field of biomedicine, can solve the problems of uneven mixing, low stability and low recovery rate, and achieve the effects of uniform product content, easy preservation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

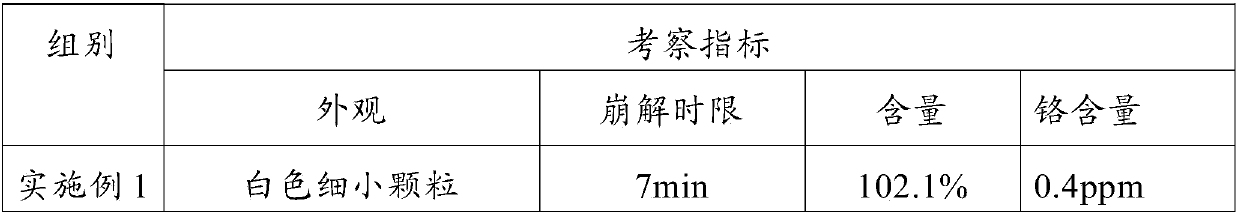

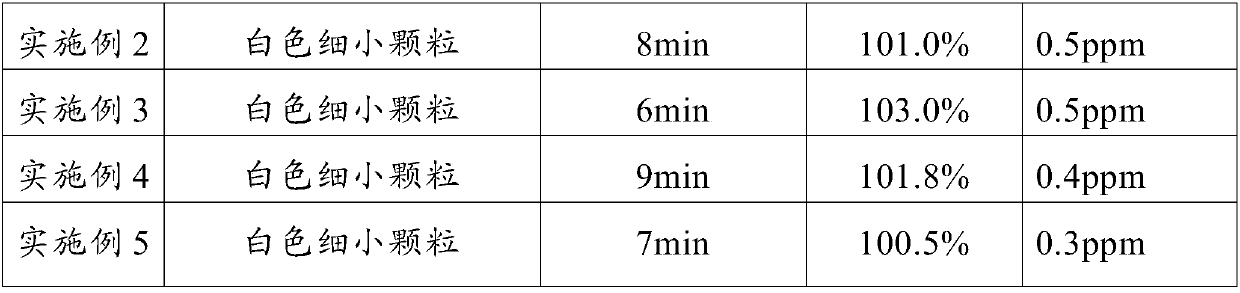

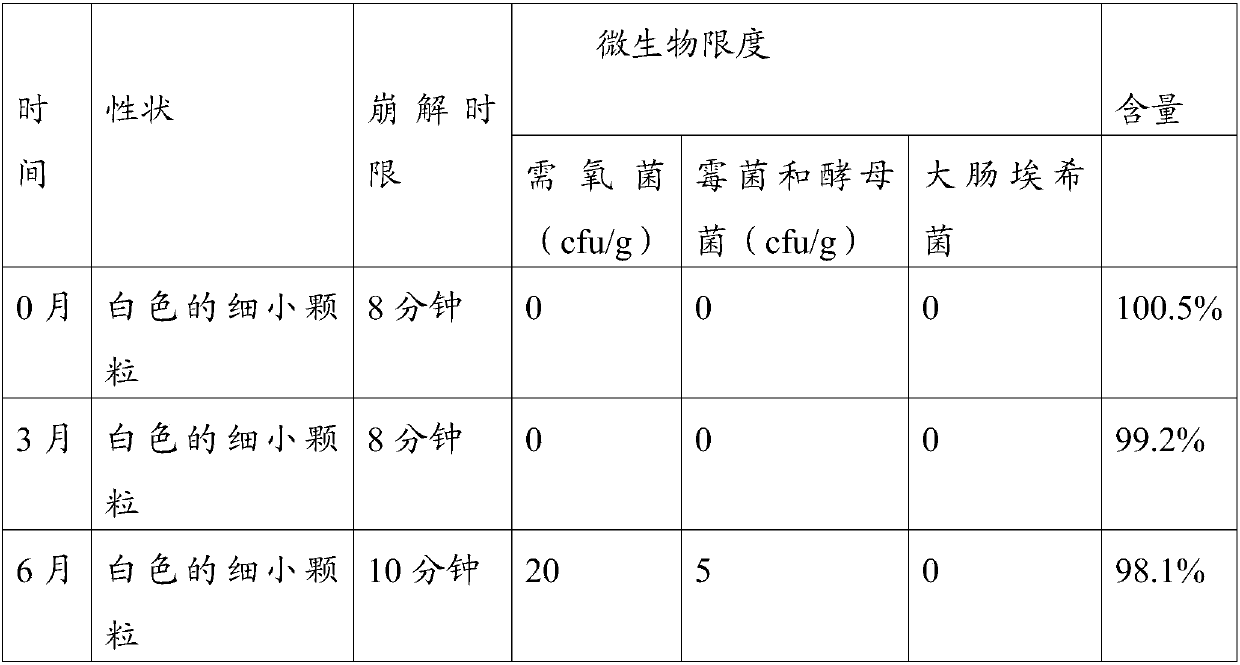

Examples

Embodiment 1

[0025] A sodium fructose diphosphate capsule, comprising the following components by weight: 100 g of sodium fructose diphosphate, 1 g of gel-process silicon dioxide, the average particle diameter of said sodium fructose diphosphate is 300 μm, and the average particle diameter of said silicon dioxide is 2 μm.

[0026] The preparation method of described sodium fructose diphosphate capsule, comprises the following steps:

[0027] (1) Material preparation: Weigh 100 g of sodium fructose diphosphate for use, and 1 g of gel-method silicon dioxide for use.

[0028] (2) Mixing: Sodium fructose diphosphate is moistened with water, and the weight ratio of sodium fructose diphosphate and water is 10:1, and gel method silicon dioxide is added to mix in a mixer. The mixing frequency of the mixer is 15Hz, a mixture was obtained.

[0029] (3) Granulation: The mixture is made into wet granules in a wet granulator filled with alcohol air flow, passed through a 20-mesh sieve, and then put i...

Embodiment 2

[0035] A sodium fructose diphosphate capsule, comprising the following components by weight: 300 g of sodium fructose diphosphate, 5 g of gel-process silicon dioxide, the average particle diameter of said sodium fructose diphosphate is 600 μm, and the average particle diameter of said silicon dioxide is 600 μm. is 14 μm.

[0036] The preparation method of described sodium fructose diphosphate capsule, comprises the following steps:

[0037] (1) Material preparation: 300 g of sieved sodium fructose diphosphate was weighed for use, and 5 g of sieved gel method silica was taken for use.

[0038] (2) Mixing: Sodium fructose diphosphate is moistened with water, the weight ratio of sodium fructose diphosphate and water is 10:5, and gel method silica is added to mix in a mixer. The mixing frequency of the mixer is 35Hz, the mixture was obtained.

[0039] (3) Granulation: make the mixture into wet granules in a wet granulator filled with alcohol air flow, pass through a 30-mesh siev...

Embodiment 3

[0045] A sodium fructose diphosphate capsule, comprising the following components in parts by weight: 150 g of sodium fructose diphosphate, 2 g of gel-formed silicon dioxide, the average particle diameter of the sodium fructose diphosphate is 400 μm, and the average particle size of the silicon dioxide is 400 μm. The diameter is 5 μm.

[0046] The preparation method of described sodium fructose diphosphate capsule, comprises the following steps:

[0047] (1) Raw material preparation: 150 g of sieved sodium fructose diphosphate was weighed for use, and 2 g of sieved gel method silica was taken for use.

[0048] (2) Mixing: Sodium fructose diphosphate is moistened with water, the weight ratio of sodium fructose diphosphate and water is 10:2, and gel method silica is added to mix in a mixer. The mixing frequency of the mixer is 20Hz, the mixture was obtained.

[0049] (3) Granulation: Make the mixture into wet granules in a wet granulator filled with alcohol airflow, pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com