Preparation method of palladium-based polyaniline coated carbon nanotube nano catalyst and application of nano catalyst in Heck reaction

A nano-catalyst, carbon nanotube technology, applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy loss, high cost, polluted products, etc., to suppress loss and agglomeration, and effectively recover. effect of separation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

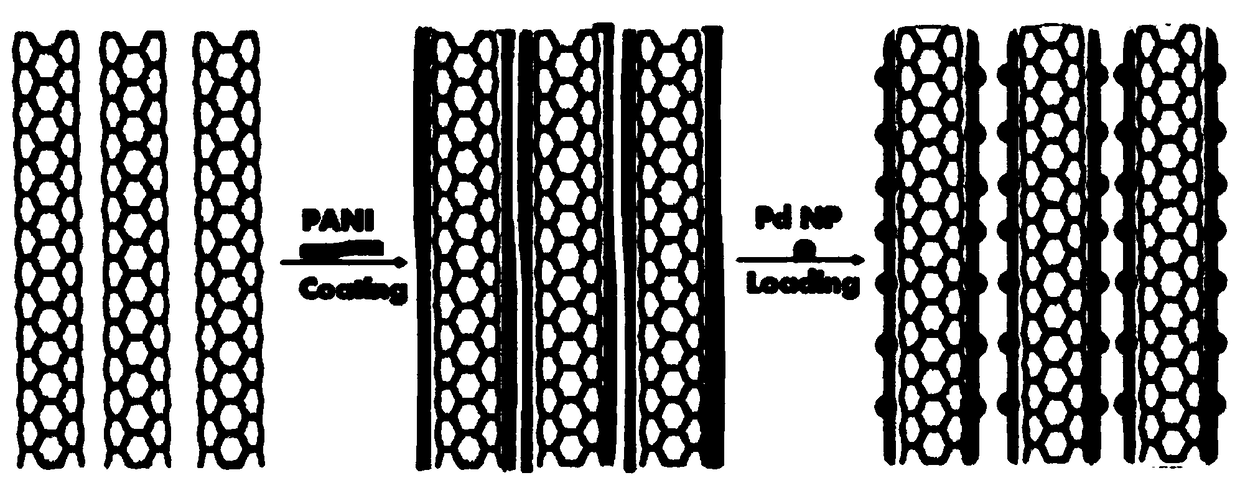

[0031] Preparation of Pd / PANI@CNT

[0032] (1) Purification of carbon nanotubes (CNTs)

[0033] Commercially purchased carbon nanotubes were placed in concentrated nitric acid solution with a mass fraction of 68%, and oxidized and refluxed at 140° C. for 14 hours. The reacted carbon nanotube suspension was first filtered by suction, then repeatedly washed and filtered with deionized water until the pH value of the filtrate was close to neutral, and a large amount of concentrated nitric acid was removed, and then placed in a water bath at 60°C. Stir in a water bath and evaporate to dryness, and finally dry the evaporated black powder in a vacuum oven at 60°C for 24 hours. Store for later use.

[0034] (2) Preparation of Polyaniline (PANI) Wrapped Carbon Nanotubes (PANI@CNT) (PANI@CNT)

[0035] In this paper, the aniline monomer is wrapped on the carbon nanotube by chemical in-situ polymerization. First, 0.25 g of aniline monomer is dissolved in 50 ml of 1 mol / L hydrochloric...

Embodiment 2

[0039] Preparation of Pd / PANI@CNT-1

[0040](1) Purification of carbon nanotubes (CNTs), this part is the same as part (1) in Example 1, and will not be repeated here;

[0041] (2) Preparation of Polyaniline (PANI) Wrapped Carbon Nanotubes (PANI@CNT) (PANI@CNT-1)

[0042] First, 1 g of aniline monomer was dissolved in 50 ml of 1 mol / L hydrochloric acid solution. At the same time, 0.5 g of acid-treated carbon nanotubes were added to another 50 ml of 1 mol / L hydrochloric acid solution, and ultrasonically dispersed for 20 min under ice-bath conditions. Then the hydrochloric acid solution in which the aniline monomer was dissolved and the hydrochloric acid solution in which the carbon nanotubes were dispersed were mixed, and stirred for 20 min. The above carbon tube-aniline mixture was transferred to an ice bath at 0-5 °C, and then ammonium persulfate (0.817 g) was added dropwise to the carbon tube-aniline mixture in 50 ml of 1 mol / L hydrochloric acid solution. The polymerizati...

Embodiment 3

[0046] Preparation of Pd / PANI@CNT-2

[0047] (1) Purification of carbon nanotubes (CNTs), this part is the same as part (1) in Example 1, and will not be repeated here;

[0048] (2) Preparation of Polyaniline (PANI) Wrapped Carbon Nanotubes (PANI@CNT) (PANI@CNT-2)

[0049] First, 2 g of aniline monomer was dissolved in 50 ml of 1 mol / L hydrochloric acid solution. At the same time, 0.5 g of acid-treated carbon nanotubes were added to another 50 ml of 1 mol / L hydrochloric acid solution, and ultrasonically dispersed for 20 min under ice-bath conditions. Then the hydrochloric acid solution in which the aniline monomer was dissolved and the hydrochloric acid solution in which the carbon nanotubes were dispersed were mixed, and stirred for 20 min. Transfer the above carbon tube-aniline mixture to an ice bath at 0-5°C, then dissolve ammonium persulfate (3.268g) in 50ml of 1mol / L hydrochloric acid solution, and add the carbon tube-aniline mixture dropwise . The polymerization reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com