Push-flow electrochemical water softening method and push-flow electrochemical water softening device

An electrochemical and water softening technology, applied in chemical instruments and methods, descaling and water softening, water/sewage treatment, etc., can solve the problems of fully mixed reactor backmixing, axial dispersion, multiple dead water areas, etc., to achieve Effects of improved softening efficiency, increased volumetric efficiency, and shortened gap between electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

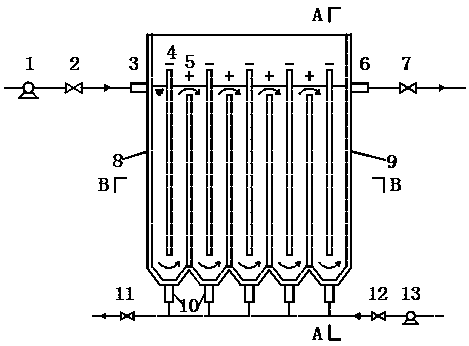

[0040] Industrial circulating water with a hardness of about 350 mg / L and a scale inhibitor concentration of about 2 mg / L is used figure 1 The plug-flow electrochemical water softening device is shown for treatment. The size of the cathode and anode electrodes is 10×10×2 cm, the distance between the electrodes is 10 mm, and the reactor volume is 1400 mL. The operating conditions are as follows: the current density in the softening stage is 40 A / m 2 The average voltage in the softening stage is 4.8V; the water flow rate in the softening stage is 40 L / h; the treatment time in the softening stage is 12 hours; the air velocity in the descaling stage is 45 L / min; The operation results are as follows: the average removal rate of total hardness ions in the effluent in the softening stage is 19.3%, and the deposition rate is 30.6 g / h / m 2 , CaCO energy consumption 5.7 kWh / kg 3 .

Embodiment 2

[0042] Industrial circulating water with a hardness of about 350 mg / L and a scale inhibitor concentration of about 2 mg / L is used figure 1The plug-flow electrochemical water softening device is shown for treatment. The size of the cathode and anode electrodes is 10×10×2 cm, the distance between the electrodes is 20 mm, and the reactor volume is 1400 mL. The operating conditions are as follows: the current density in the softening stage is 10 A / m 2 ; The average voltage in the softening stage was 6.5V, and the water flow rate in the softening stage was 80 L / h; the treatment in the softening stage lasted 9 hours; the air velocity in the descaling stage was 25 L / min; The running results are as follows: the average removal rate of total hardness ions in the softening stage is 13.5%, and the deposition rate is 14.4 g / h / m 2 , CaCO energy consumption 11.2 kWh / kg 3 .

Embodiment 3

[0044] Industrial circulating water with a hardness of about 350 mg / L and a scale inhibitor concentration of about 2 mg / L is used figure 1 The plug-flow electrochemical water softening device is shown for treatment. The size of the positive and negative electrodes is 10×10×2 cm, the distance between the electrodes is 2 mm, and the reactor volume is 1400 mL. The operating conditions are as follows: the current density in the softening stage is 300 A / m 2 ; The average voltage in the softening stage is 12.2V; the water flow rate in the softening stage is 60 L / h; the treatment time in the softening stage is 6 h; the air velocity in the descaling stage is 60 L / min; The operation results are as follows: the average removal rate of total hardness ions in the effluent in the softening stage is 16.1%, and the deposition rate is 105.74 g / h / m 2 , CaCO energy consumption 56.2 kWh / kg 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com