Lubricant for high-speed filling line and preparation method thereof

A filling line and lubricant technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems that the production cannot be carried out normally, the lubricity is difficult to meet, the filling amount deviation, etc., and achieve good ecological safety and compatibility. , Significant thickening effect, low surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

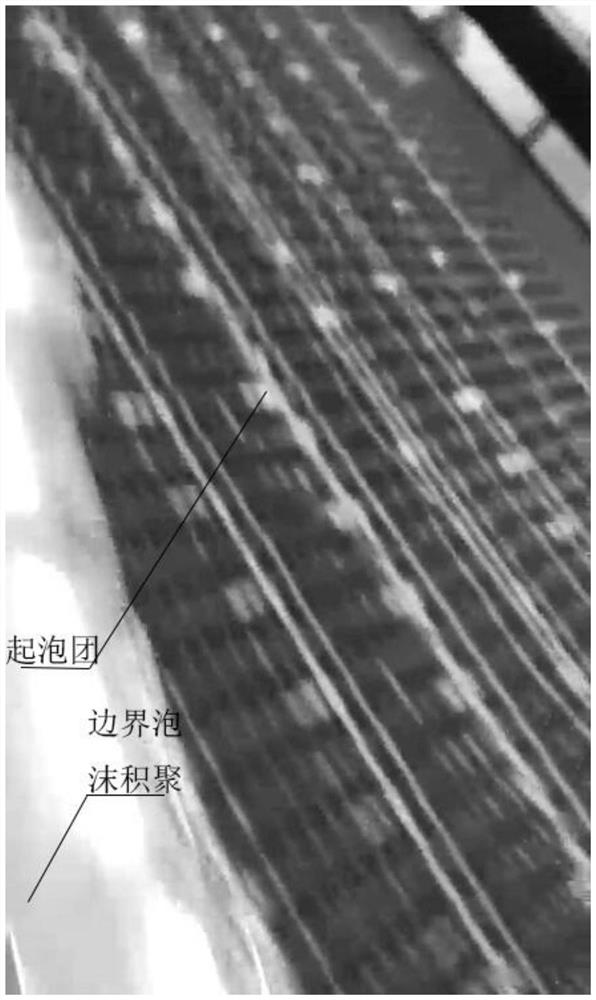

Image

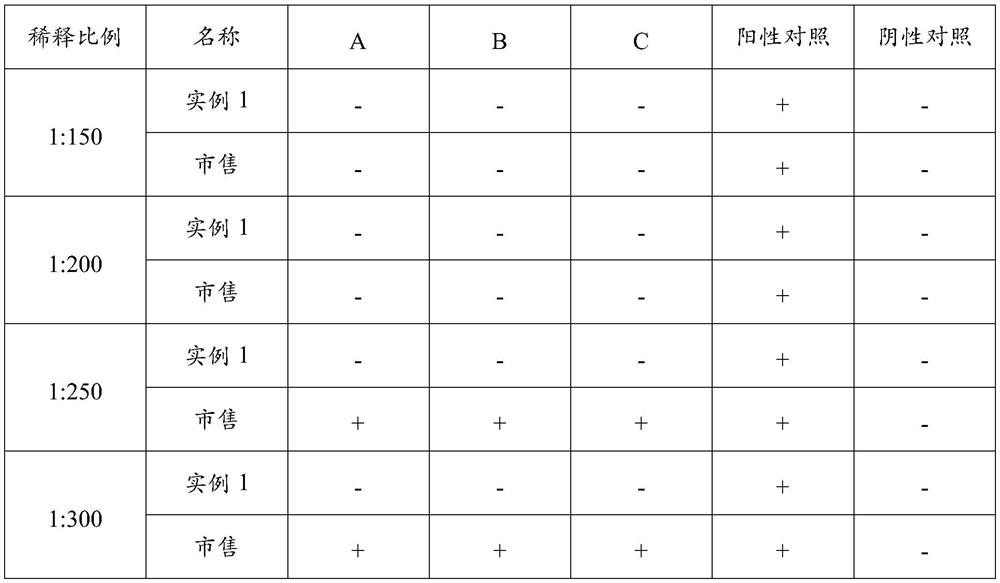

Examples

Embodiment 1

[0039] A high-speed filling line lubricant, its raw materials are: RPE1740 10g, APG0810 6g, APG08142g, fatty alcohol ether phosphate 5g, edetate disodium 3.8g, isothiazolinone 2.5g, ethanol 3g, Water 67.7g.

[0040] Step (1): taking each raw material according to the above weight;

[0041] Step (2): Add RPE1740, APG0810, and APG0814 into water in turn, stir to disperse evenly, and control the stirring time within 10-15 minutes;

[0042] Step (3): Add fatty alcohol ether phosphate to the mixed solution obtained in step (2), stir to disperse evenly, and control the stirring time to 5-10 minutes;

[0043] Step (4): Add disodium edetate to the mixed solution obtained in step (3), stir to disperse evenly, and control the stirring time to 10-15 minutes;

[0044] Step (5): sequentially add isothiazolinone and ethanol to the mixed solution obtained in step (4) and stir evenly; thereby prepare a lubricant for a high-speed filling line.

[0045] The above steps (1)-(5) are carried out ...

Embodiment 2

[0047] A lubricant for high-speed filling line, its raw material composition is: RPE1740 12g, APG0810 7g, fatty alcohol ether phosphate 5.5g, disodium edetate 4g, isothiazolinone 2.5g, ethanol 2.5g, water 66.5g.

[0048] Step (1): taking each raw material according to the above weight;

[0049] Step (2): Add RPE1740 and APG0810 into water in turn, stir to disperse evenly, and control the stirring time within 10-15 minutes;

[0050] Step (3): Add fatty alcohol ether phosphate to the mixed solution obtained in step (2), stir to disperse evenly, and control the stirring time to 5-10 minutes;

[0051] Step (4): Add disodium edetate to the mixed solution obtained in step (3), stir to disperse evenly, and control the stirring time to 10-15 minutes;

[0052] Step (5): sequentially add isothiazolinone and ethanol to the mixed solution obtained in step (4) and stir evenly; thereby prepare a lubricant for a high-speed filling line.

[0053] The above steps (1)-(5) are carried out at ...

Embodiment 3

[0055] A lubricant for high-speed filling line, its raw material composition is: RPE1740 5g, APG0810 8g, APG0814 4g, fatty alcohol ether phosphate 2g, edetate disodium 5g, isothiazolinone 1g, ethanol 8g, water 45g.

[0056] Step (1): taking each raw material according to the above weight;

[0057] Step (2): Add RPE1740 and APG0810 into water in turn, stir to disperse evenly, and control the stirring time within 10-15 minutes;

[0058] Step (3): Add fatty alcohol ether phosphate to the mixed solution obtained in step (2), stir to disperse evenly, and control the stirring time to 5-10 minutes;

[0059] Step (4): Add disodium edetate to the mixed solution obtained in step (3), stir to disperse evenly, and control the stirring time to 10-15 minutes;

[0060] Step (5): sequentially add isothiazolinone and ethanol to the mixed solution obtained in step (4) and stir evenly; thereby prepare a lubricant for a high-speed filling line.

[0061] The above steps (1)-(5) are carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com