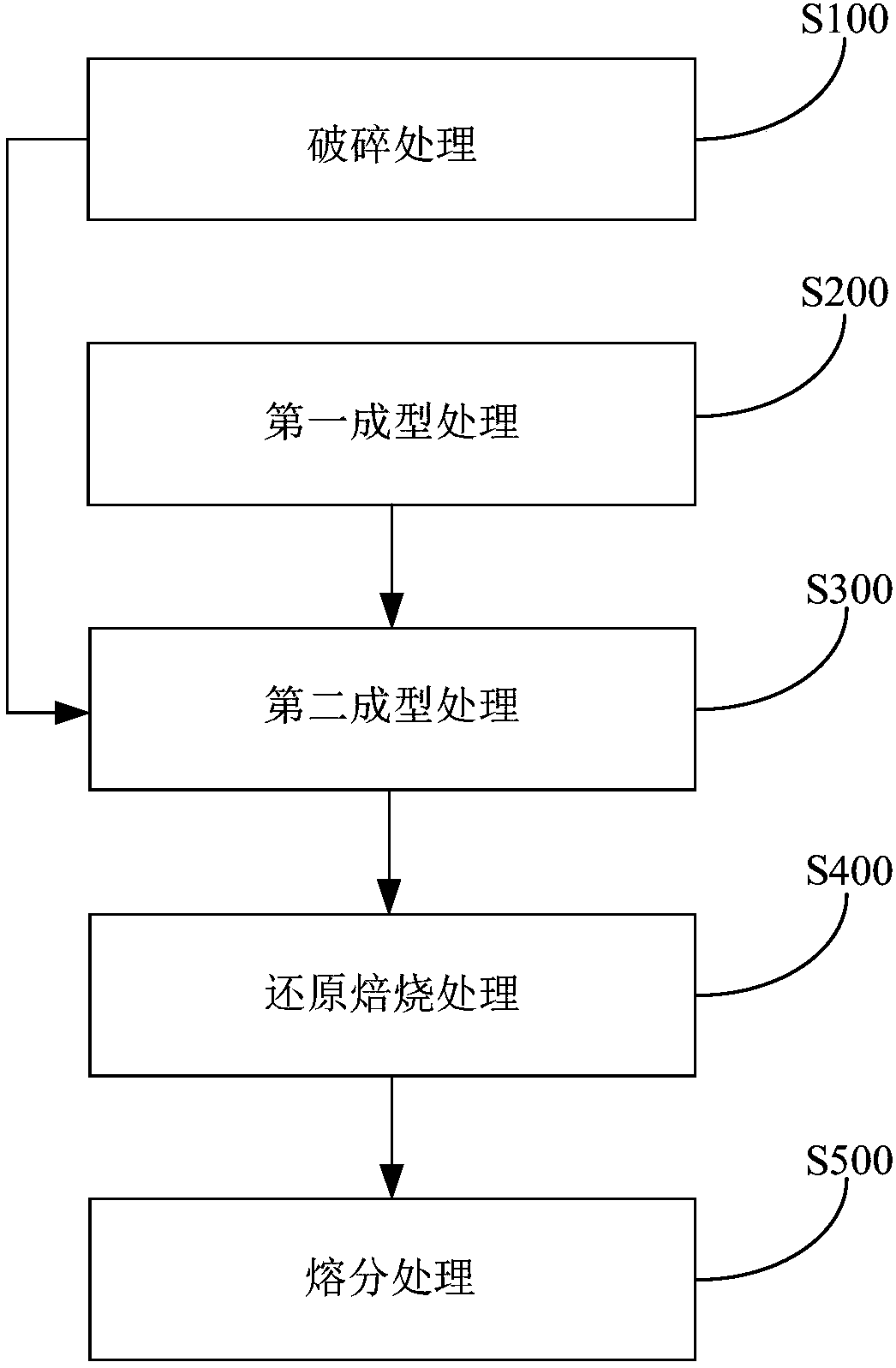

Method and system of treating tin-containing lead slag

A tin-lead and pellet technology, applied in the field of metallurgy, can solve the problems of great potential harm to the ecological environment, waste of resources, difficult to decompose, etc., and achieve the effects of significant economic and environmental benefits and low energy consumption costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

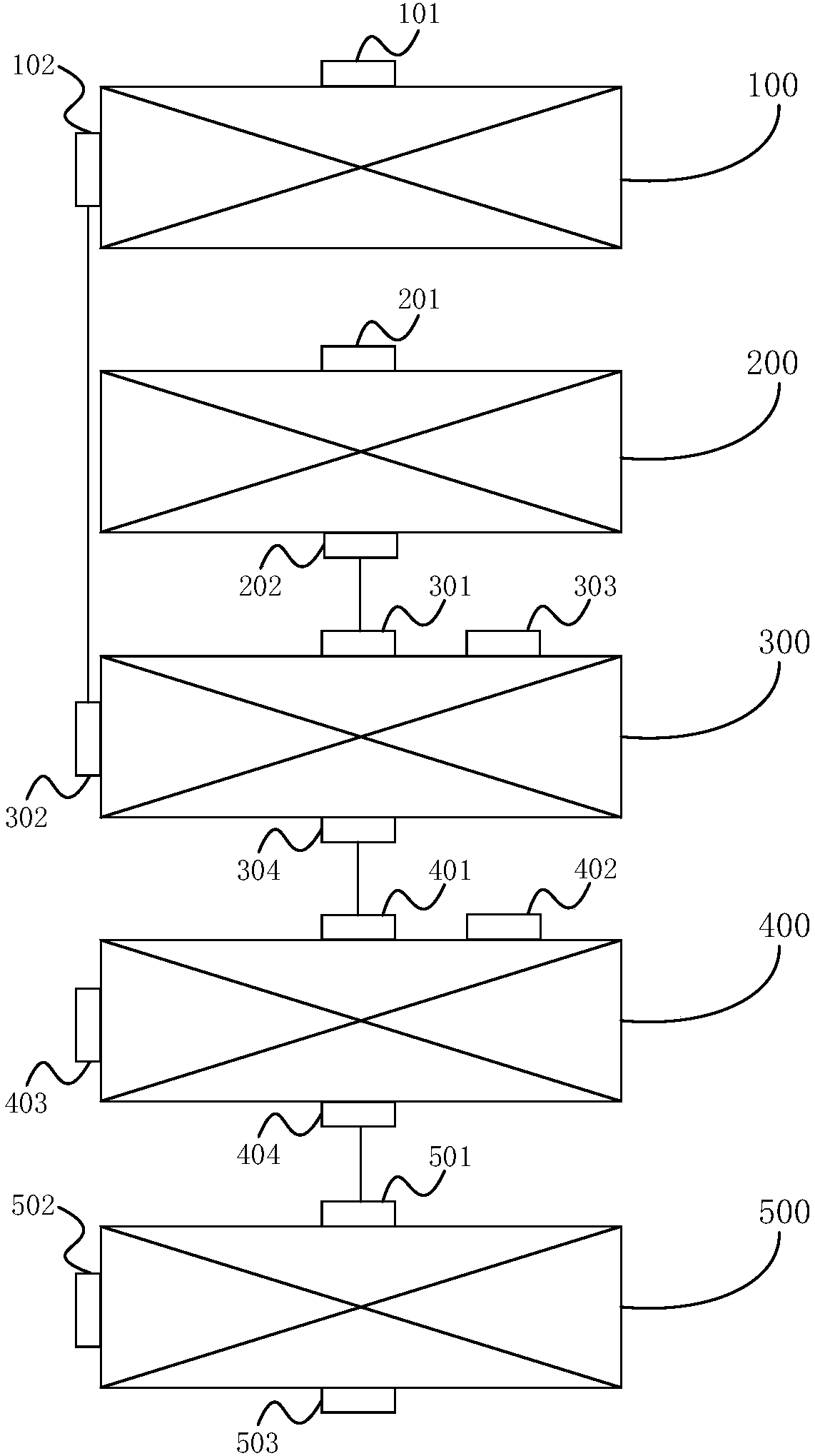

Embodiment 1

[0069] Composition of tin-lead slag: 26wt% TFe, 6wt% lead, 8wt% zinc, 0.8wt% tin, crush the tin-lead slag to less than 0.5mm, first make lignite cue balls, the diameter of the pellets is 5-10mm, and Mix tin-lead slag and dolomite, tin-lead slag, brown coal, and dolomite in a ratio of 10:2.9:1.2, wrap the mixture of tin-lead slag and dolomite outside the lignite cue ball, four Basic alkalinity is 0.8. After drying the prepared pellets, put them into the rotary hearth furnace for roasting, the rotary hearth furnace is equipped with a preheating zone, SnO 2 Reduction zone and discharge zone, SnO 2 The reduction zone temperature is set to 910°C, the reduction time is 22min, SnO 2 The concentration of CO in the reduction zone is 2v%, and the concentration of oxygen is 1v%. After the pellets pass through the rotary hearth furnace, the SnO 2 SnO in the tin-containing dust collected from the flue in the reduction zone 2 The content is 42wt%, the tin content in the metallized pelle...

Embodiment 2

[0071] Composition of tin-lead slag: 30wt% TFe, 4.1wt% lead, 3.8wt% zinc, 0.6wt% tin, crush the tin-lead slag to less than 0.5mm, first make lignite cue balls, the diameter of the pellets is 5-10mm , after the tin-lead slag is crushed, mix the tin-lead slag scrap with dolomite, and mix the tin-lead slag and dolomite with the ratio of 10:3.1:1.3 The mixture is wrapped outside the lignite cue ball, and the quaternary alkalinity is 1.0. After drying the prepared pellets, put them into the rotary hearth furnace for roasting, the rotary hearth furnace is equipped with a preheating zone, SnO 2 Reduction zone and discharge zone, SnO 2 The reduction zone temperature is set to 950°C, the reduction time is 25min, SnO 2 The CO concentration in the reduction zone is 4v%, and the oxygen concentration is 1.3v%. After the pellets pass through the rotary hearth furnace, the SnO 2 SnO in the tin-containing dust collected from the flue in the reduction zone 2 The content is 45wt%, the tin c...

Embodiment 3

[0073] Tin-containing lead slag composition: TFe 34wt%, lead 2.7wt%, zinc 3.2wt%, tin 0.4wt%, the tin-lead slag is crushed to less than 0.5mm, and lignite is first made into cue balls, and the diameter of the pellets is 5-10mm , after the tin-lead slag is crushed, mix the tin-lead slag fragments with dolomite, and mix the tin-lead slag and dolomite with the tin-lead slag fragments, lignite and dolomite according to the ratio of 10:3.3:1.4 The mixture is wrapped outside the lignite cue ball, and the quaternary alkalinity is 1.2. After drying the prepared pellets, put them into the rotary hearth furnace for roasting, the rotary hearth furnace is equipped with a preheating zone, SnO 2 Reduction zone and discharge zone, SnO 2 The reduction zone temperature is set to 980°C, the reduction time is 28min, the SnO 2 The CO concentration in the reduction zone is 5.6v%, and the oxygen concentration is 1.7v%. After the pellets pass through the rotary hearth furnace, the SnO 2 SnO in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com