Separation membrane carrier and application thereof

A separation membrane and carrier technology, applied in the field of membrane separation, can solve the problems of carrier layer transmission resistance, lower separation membrane flux, and lower packing density of components, so as to improve flux and selectivity, facilitate production and maintenance, and increase packing density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1. Preparation of separation membrane carrier

[0047] The separation membrane carrier is prepared by a conventional extrusion method, and the material is alumina.

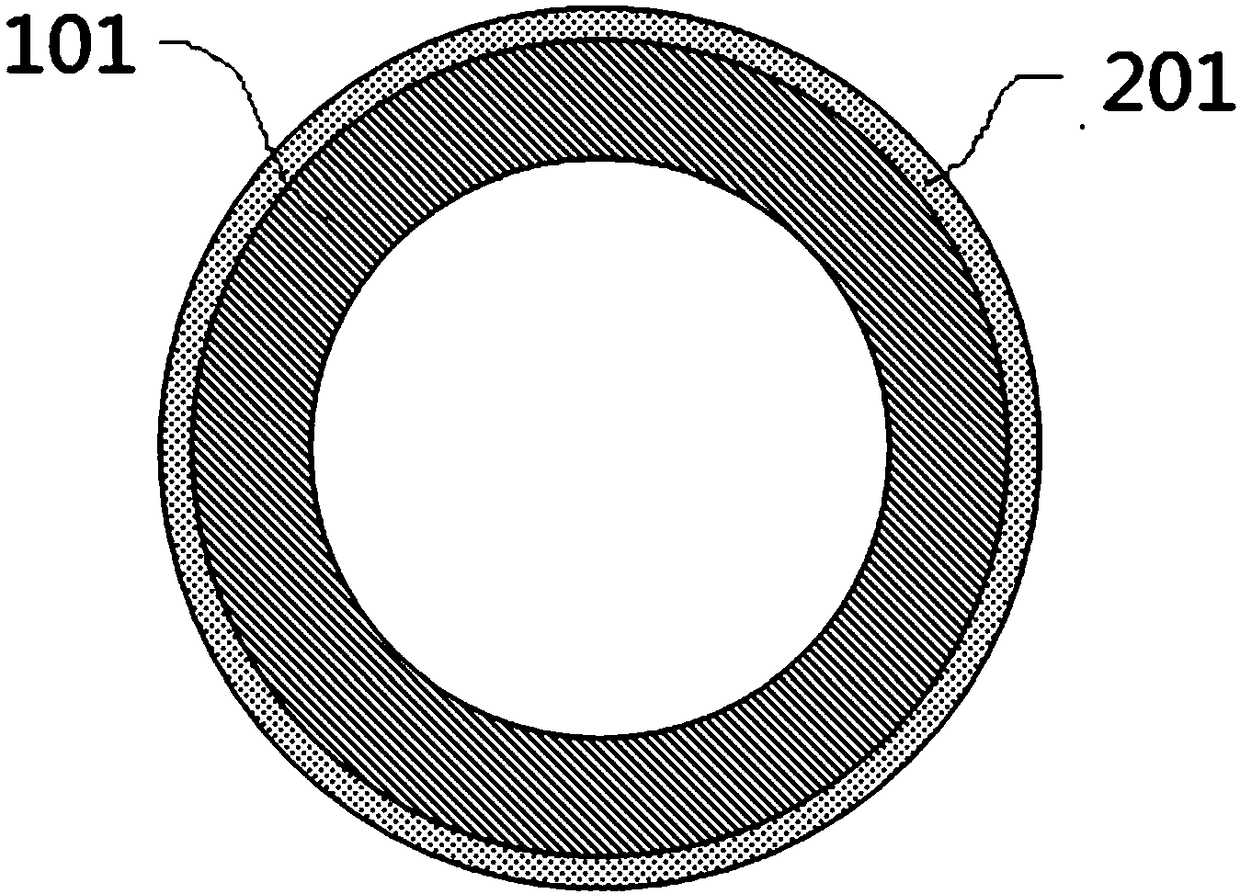

[0048] Carrier A: round tube support body, length 100mm; outer diameter 12mm, inner diameter 8mm;

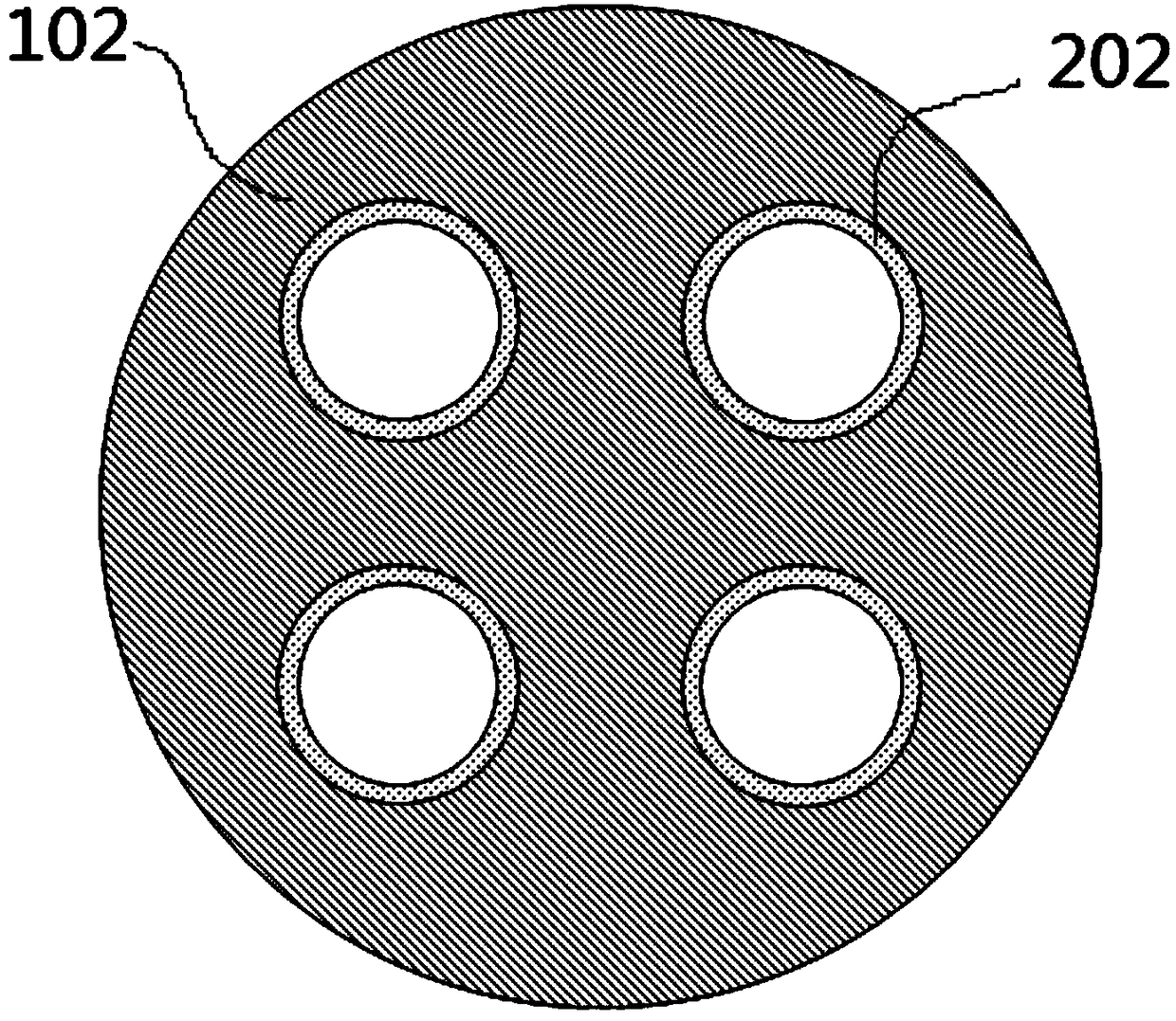

[0049] Carrier B: four-channel circular tube support body, length 100mm; outer diameter 16mm: channel inner diameter 4mm;

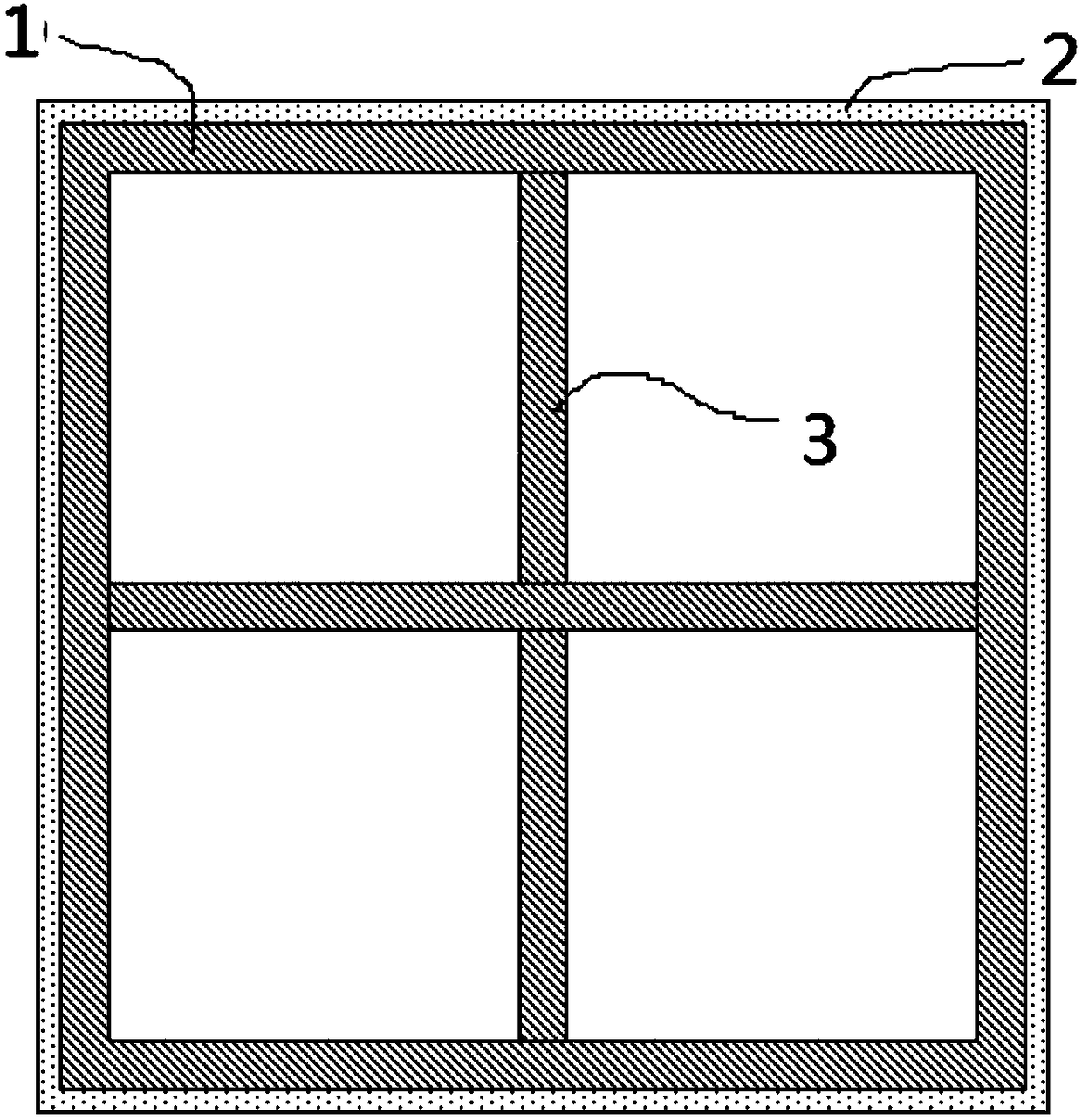

[0050]Carrier C: square support body, length 100mm; section 10mmX10mm, with cross support ridge inside, wall thickness 1mm;

[0051] Carrier D: plate support body, length 100mm; section 5mmX30mm, internal 2mm interval support, wall thickness 1mm.

Embodiment 2

[0052] Embodiment 2. The synthesis of composite separation membrane:

[0053] (1) Synthetic method of NaA type molecular sieve membrane: the synthetic solution of synthetic molecular sieve membrane is formed by mixing silica sol, NaOH, aluminum foil and distilled water, and the proportioning ratio (molar ratio) of the synthetic solution finally obtained is: 50Na 2 O: Al 2 o 3 :5SiO2 2 :1000H 2 O. Expose the surface of the carrier to be coated, place it in the reaction kettle, carefully add the synthesis solution and close the lid of the kettle tightly. After reacting at 90° C. for 6 hours, the synthesized molecular sieve membrane was taken out, washed with distilled water, soaked until neutral, and dried overnight in an oven. In order to obtain a molecular sieve membrane with good separation performance, the above steps are repeated once.

[0054] (2) Synthesis of NaX type molecular sieve membrane

[0055] The synthetic liquid for synthesizing molecular sieve membrane i...

Embodiment 3

[0061] Embodiment 3. Composite molecular sieve membrane performance test test

[0062] 1. Test method

[0063] (1) The flexural strength shall be in accordance with the provisions in 5.4 of HY / T064-2002.

[0064] (2) The measuring method of separation performance is: investigate the performance of pervaporation dehydration of molecular sieve membrane, operating temperature is 50 ℃, raw material liquid is ethanol aqueous solution containing 90% ethanol. By analyzing and measuring the composition of the permeate and the quality of the permeate collected per unit time, the water / ethanol separation coefficient and permeate flux are calculated according to the following formula.

[0065] Separation factor: Indicates the ratio of the relative content of two substances in the material before and after the molecular sieve membrane separation operation. It is defined as:

[0066]

[0067] In the formula, i / j represents the separation coefficient of the molecular sieve membrane fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com