3D printing process for photosensitive resin

A 3D printing, photosensitive resin technology, applied in the field of 3D printing, can solve the problem that it is only suitable for printing specific printing materials, and achieve the effect of excellent surface quality and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

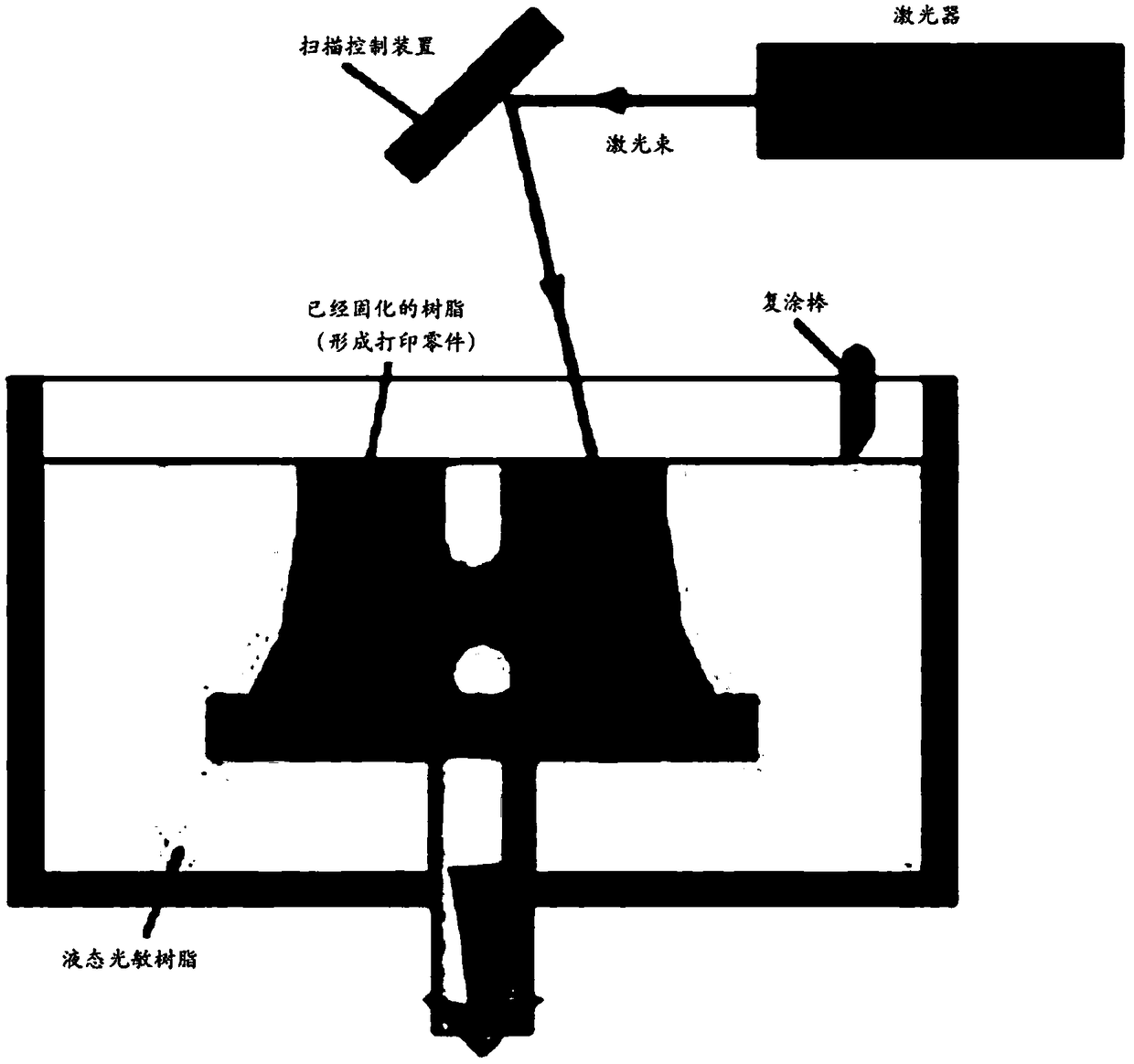

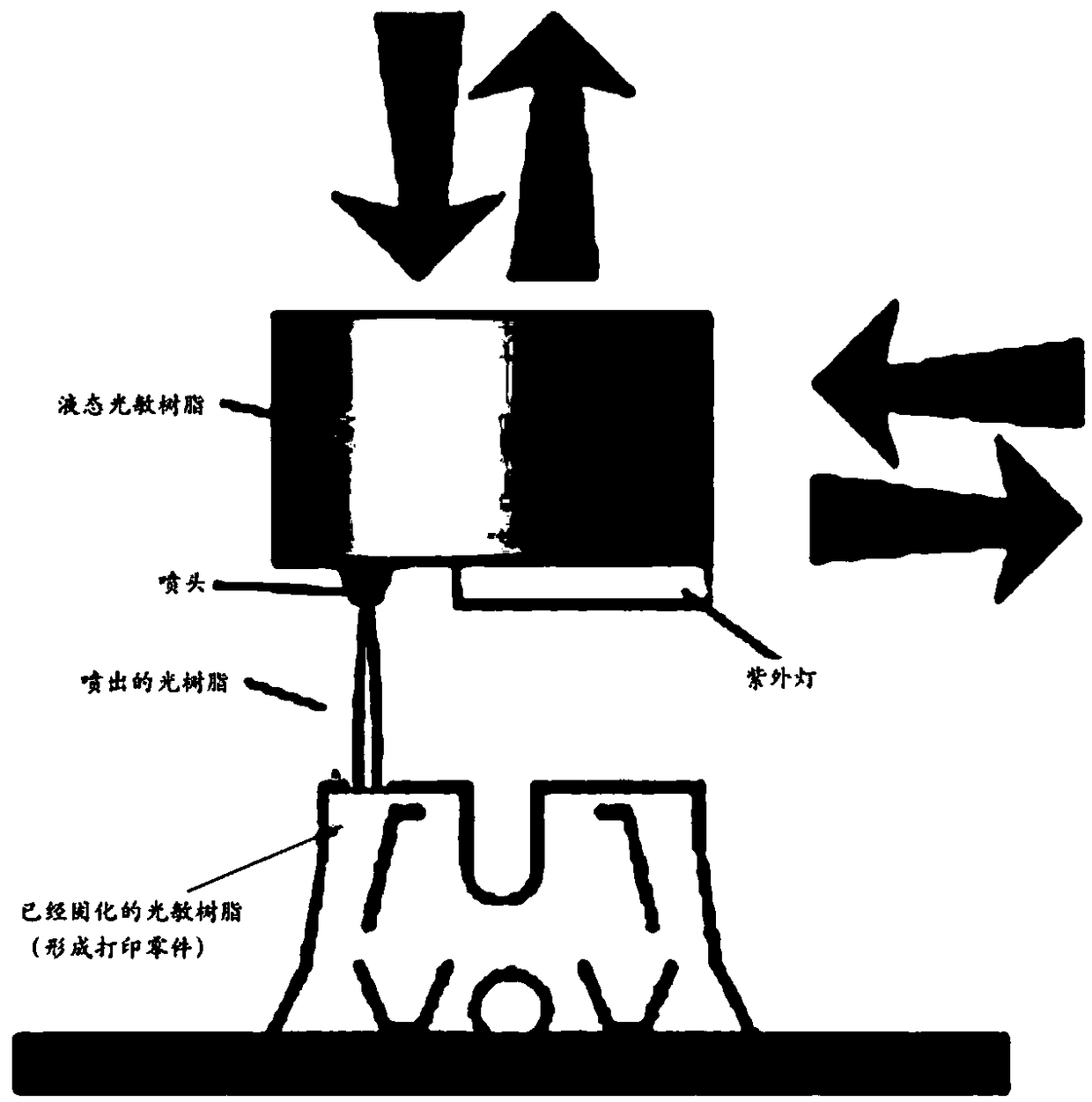

[0015] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Photosensitive resin is a printing material that is stable and liquid in the raw material state. These resins usually include components such as polymer monomers, prepolymers, and ultraviolet photoinitiators. During the printing process, ultraviolet laser irradiation can make it instantly solidify. Therefore, this type of printing consumables has good surface drying performance, smooth and smooth surface after molding, high product resolution, excellent detail display, and the quality even exceeds injection molding products. These outstanding advantages make photosensitive resin the first choice for high-end and artistic 3D printing products. However, the cost of current photosensitive resins is still high, and the mechanical strength, heat resistance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com