Composite material anti-bird strike baffle for aircraft nose

A composite material board and composite material technology are applied in the field of composite material anti-bird-collision baffles for aircraft noses, which can solve the problems of large influence on the maintainability of radomes, blocking passages for radome disassembly, and unfavorable aircraft economy. Achieve the effect of improving maintainability, strong impact resistance and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

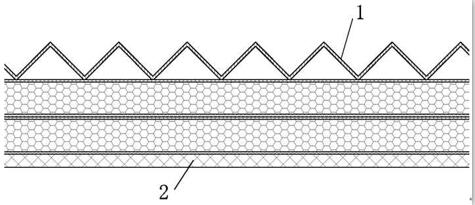

[0027] The composite material anti-bird impact baffle for aircraft nose is composed of tooth plate 1 and composite material plate 2, such as figure 1 shown.

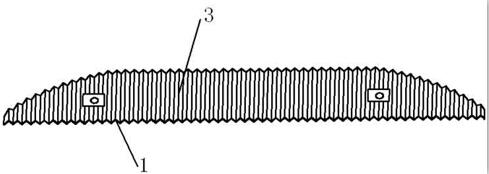

[0028] The tooth plate 1 is made of 2024-T3 aluminum alloy plate with a thickness of 1.5mm, and the surface is distributed with continuous protrusions 3, such as figure 2 shown. The protrusion 3 is a strip-like structure with an inverted V-shaped cross-section, a sharp-angled structure at the top, and a taper angle of 135° at the top. The tooth plate 1 is provided with a connecting hole, and the surrounding area of the hole is a plane structure.

[0029] The composite material board 2 consists of three layers, the first and second layers are sandwich panels, which are formed by bonding the upper and lower skins and the honeycomb sandwich core, and the third layer is an aramid fiber composite material board. Among them, the upper and lower skins of the first layer of sandwich panels are both aramid fiber composite p...

Embodiment 2

[0033] The composite material anti-bird-collision baffle for the aircraft nose is composed of a tooth plate 1 and a composite material plate 2 .

[0034] The tooth plate 1 is made of 2024-T3 aluminum alloy plate with a thickness of 1.2mm, and the surface is distributed with continuous protrusions 3. The protrusion 3 is a strip-shaped structure with an inverted V-shaped cross-section, a rounded corner structure at the top, and a taper angle of 120° at the top. The tooth plate 1 is provided with a connecting hole, and the surrounding area of the hole is a plane structure.

[0035] The composite material board 2 is composed of four layers, the first and third layers are sandwich panels, which are formed by bonding the upper and lower skins and the honeycomb sandwich core, and the second and fourth layers are aramid fiber composite material boards. The upper and lower skins of the two-layer sandwich panels are both carbon fiber composite panels, made of unidirectional carbon fi...

Embodiment 3

[0039] The composite material anti-bird-collision baffle for the aircraft nose is composed of a tooth plate 1 and a composite material plate 2 .

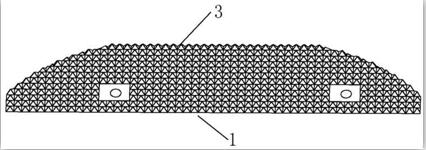

[0040] The tooth plate 1 is made of 2024-T3 aluminum alloy plate with a thickness of 1mm, and the surface is distributed with continuous protrusions 3, such as image 3 shown. The protrusion 3 is a pyramid structure, the upper tip is below, the bottom edge is square, the side length is 44mm, and the angle between the opposite cone surfaces is 90°.

[0041] The composite material panel 2 consists of three layers, all of which are sandwich panels, such as Figure 4 As shown, it is formed by bonding the upper and lower skins and the honeycomb core. Among them, the upper and lower skins of the first layer of sandwich panels are polyethylene fiber composite panels, made of polyethylene fiber orthogonal cloth and epoxy resin, with a density of 1.0 g / cm 3 , 1mm thick; the upper and lower skins of the second and third layers of sandwich ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com