A kind of synthetic method of anthranilic acid

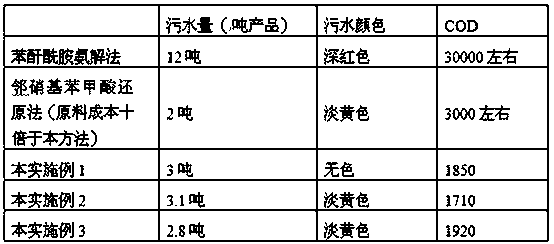

A technology of anthranilic acid and a synthesis method, which is applied in the field of synthesis of anthranilic acid, can solve the problems of large pollution, low yield, low purity of anthranilic acid, etc., and achieves low environmental pollution, high utilization rate, and waste water volume. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

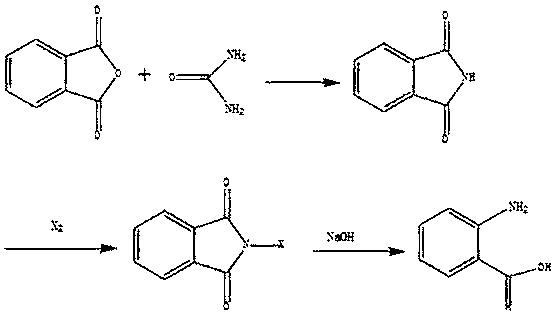

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the present invention provides a kind of synthetic method of anthranilic acid, specifically comprises the following steps:

[0025] (1) Put 600g of phthalic anhydride and 150g of urea into a three-necked flask, heat up to 140°C and stir for half an hour;

[0026] (2) After the reaction is complete, add 1000g of water for beating, and add 600g of glacial acetic acid;

[0027] (3) Pass in about 400g of chlorine gas under stirring, and absorb the excess chlorine gas with liquid caustic;

[0028] (4) After stirring and reacting at room temperature for three hours, filter to obtain the solid, wash the solid with 100 g of water, and put the mother liquor into the next batch of reaction liquid;

[0029] (5) Put the solid into 1800g of sodium hydroxide solution, the mass percentage concentration is 30%, and stir at room temperature for one hour;

[0030] (6) Add hydrochloric acid to the reaction solution to adjust the pH to 3-4, and a large amount of solids are ...

Embodiment 2

[0033] Embodiment 2: the present invention provides a kind of synthetic method of anthranilic acid, specifically comprises the following steps:

[0034] (1) Put 600g of phthalic anhydride and 150g of urea into a three-necked flask, heat up to 140°C and stir for half an hour;

[0035] (2) After the reaction is completed, add 1500 g of the mother liquor obtained by filtering the previous batch of products to make a slurry (specifically step 4 in Example 1 to obtain the mother liquor);

[0036] (3) Pass in about 400g of chlorine gas under stirring, and absorb the excess chlorine gas with liquid caustic;

[0037] (4) After stirring and reacting at room temperature for three hours, filter to obtain the solid, wash the solid with 100 g of water, and put the mother liquor into the next batch of reaction liquid;

[0038] (5) Put the solid into 1800g liquid caustic soda, stir at room temperature for one hour, and the liquid caustic soda adopts a sodium hydroxide solution with a concen...

Embodiment 3

[0042] Embodiment 3: the present invention provides a kind of synthetic method of anthranilic acid, specifically comprises the following steps:

[0043] (1) Put 600g of phthalic anhydride and 150g of urea into a three-necked flask, heat up to 140°C and stir for half an hour;

[0044] (2) After the reaction is complete, add 1000g of water for beating, and add 600g of glacial acetic acid;

[0045] (3) Add 650g of bromine while stirring, and absorb the excess bromine with liquid caustic soda;

[0046] (4) After stirring and reacting at room temperature for three hours, the solid was obtained by filtration, and the mother liquor was put into the next batch of reaction liquid;

[0047] (5) Put the solid into 1800g liquid caustic soda, stir at room temperature for one hour, and the liquid caustic soda adopts a potassium hydroxide solution with a concentration of 40% by mass;

[0048] (6) Add hydrochloric acid to the reaction solution to adjust the pH to 3-4, and a large amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com