Aromatic polyether monomer, special phenolic aldehyde main chain structure water reducing agent derived from same and preparation methods thereof

A technology of polyether monomer and main chain structure, applied in the field of aromatic polyether monomer, can solve the problems of high viscosity, limited strength improvement and poor adaptability of water reducing agent, and achieve low viscosity, water reducing performance and slump retention. Good performance, the effect of improving early strength and final setting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In a specific embodiment, the application provides a kind of preparation method of high molecular weight polyether monomer, it comprises the following steps:

[0048] (1) initiator is mixed with catalyst to obtain mixture 1;

[0049] (2) The resulting mixture 1, ethylene oxide and propylene oxide are mixed for ring-opening polymerization;

[0050] (3) maturation, get final product;

[0051] The initiator is one or more of phenol, ethylene glycol phenyl ether, p-cresol and p-cresyl glycol ether.

[0052] In the present application, the catalyst is conventional in the art, preferably one or more of alkali metals, alkali metal hydroxides, alkaline earth metal hydroxides and alkali metal oxides; more preferably potassium hydroxide , sodium hydroxide, potassium methylate, sodium methylate and sodium metal in one or more.

[0053] In the present application, the initiator: catalyst: ethylene oxide: the parts by weight of propylene oxide are preferably (90-140): (1-5): (244...

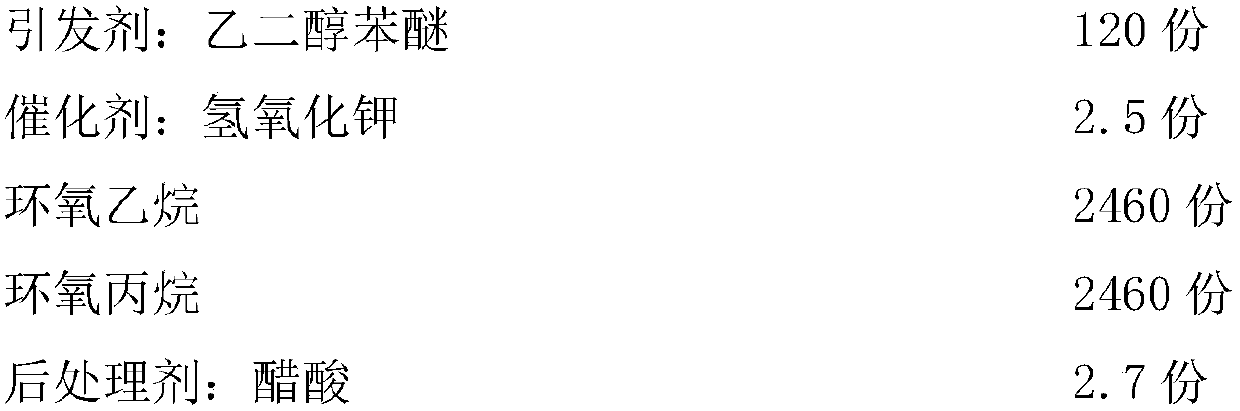

Embodiment 1

[0087] The raw material formula that present embodiment adopts is as follows:

[0088] Preparation:

[0089]

[0090] Mix the initiator and catalyst, vacuum inhale the ethoxylation device, turn on the canned pump, then raise the temperature to 100°C, and vacuum dehydrate for 2 hours. =1:1) At the same time, gradually add epoxide and mature for 2 hours. During the whole reaction process, the pressure of the reaction system is controlled at 0.1-0.4MPa; then cool down to 75°C and add neutralizing agent acetic acid, and stir evenly.

[0091] The hydroxyl value of the high molecular weight polyether monomer prepared in this example is 11.12 mgKOH / g.

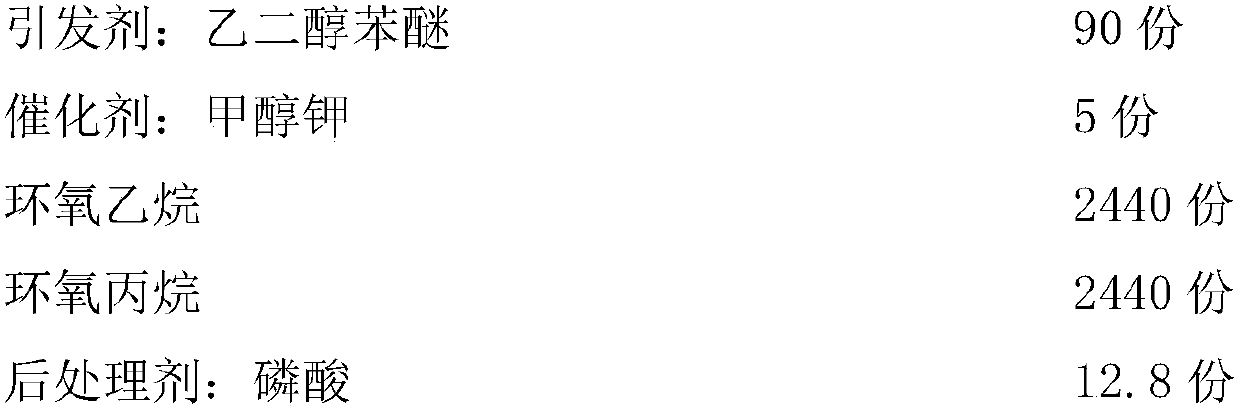

Embodiment 2

[0093] The raw material formula that present embodiment adopts is as follows:

[0094] Preparation:

[0095]

[0096] Mix the initiator and catalyst, vacuum inhale the ethoxylation device, turn on the canned pump, then raise the temperature to 105°C, and vacuum dehydrate for 2 hours. =1:1) At the same time, gradually add epoxide and mature for 2 hours. During the whole reaction process, the pressure of the reaction system is controlled at 0.1-0.4MPa; then cool down to 78°C and add neutralizing agent acetic acid, and stir evenly.

[0097] The hydroxyl value of the high molecular weight polyether monomer prepared in this example is 11.25 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com