Cobalt ion-doped metal-organic framework material and preparation method thereof

A metal-organic framework and cobalt ion technology, applied in chemical instruments and methods, other chemical processes, water treatment of special compounds, etc., can solve the problem of low-cost, large-scale production of UiO-66, poor photocatalytic activity, adsorption Poor performance and other problems, to achieve enhanced photocatalytic performance, good application prospects, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

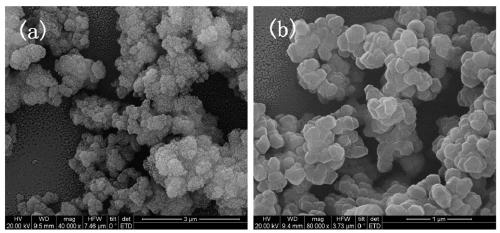

[0035] A metal-organic framework material doped with cobalt ions, comprising cobalt ions and UiO-66(Zr), wherein cobalt ions are doped in UiO-66(Zr).

[0036] In this example, the specific surface area of the metal-organic framework material doped with cobalt ions is 815.178 m 2 / g.

[0037] A method for preparing the cobalt ion-doped metal-organic framework material of the above-mentioned embodiment, specifically, using zirconium chloride, terephthalic acid, and cobalt chloride hexahydrate as raw materials to prepare cobalt ion-doped A metal organic framework material comprising the steps of:

[0038] (1) According to the molar ratio of zirconium chloride, terephthalic acid, N,N-dimethylformamide being 1:1:162 and the molar ratio of cobalt chloride hexahydrate and zirconium chloride being 1:1, the Zirconium chloride, terephthalic acid, and cobalt chloride hexahydrate were dispersed in N,N-dimethylformamide, and stirred for 1 hour at a rotational speed of 300 r / min to obta...

Embodiment 2

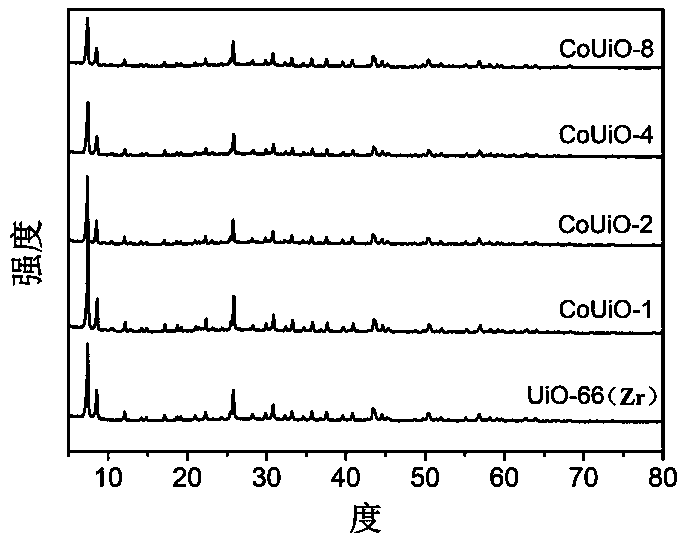

[0041] A method for preparing a cobalt ion-doped metal-organic framework material is basically the same as that in Example 1, except that the molar ratio of cobalt chloride hexahydrate and zirconium chloride in Example 2 is 1:2.

[0042] The cobalt ion-doped metal-organic framework material prepared in Example 2 is named CoUiO-2.

Embodiment 3

[0044] A method for preparing a cobalt ion-doped metal-organic framework material is basically the same as that in Example 1, except that the molar ratio of cobalt chloride hexahydrate and zirconium chloride in Example 3 is 1:4.

[0045] The cobalt ion-doped metal-organic framework material prepared in Example 3 is named CoUiO-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com